يوفر جهاز التشفير الدوَّار التزايدي GOS38B التشفير الدوَّار التزايدي موثوقًا ودقيقًا للموضع والسرعة لمجموعة كبيرة من تطبيقات الأتمتة الصناعية. تم تصميم أداة التشفير هذه بغطاء قوي بقطر 38 مم وعمود صلب 6 مم، وتوفر دقة نبضات متعددة مصممة خصيصًا لتلبية متطلبات التحكم المتنوعة. تضمن دائرته المتطورة المضادة للتداخل وتصميمه المتين أداءً مستقرًا في البيئات القاسية، مما يجعله مثاليًا للمحركات والناقلات وماكينات التغليف وأنظمة التحكم الرقمي باستخدام الحاسوب. يتوافق GOS38B مع أنظمة تحكم متعددة، مما يوفر خرج إشارة متناسق لتحسين كفاءة الماكينة ودقتها.

الميزات الرئيسية

مشفر دوّار تزايدي مع دقة نبضات تتراوح من 100 إلى 5000 نبضة لكل دورة

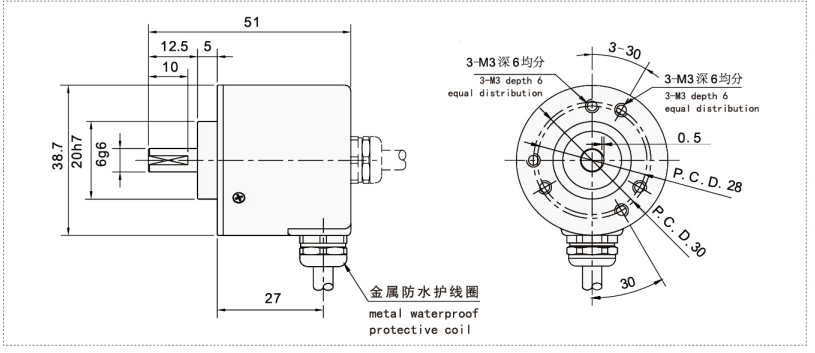

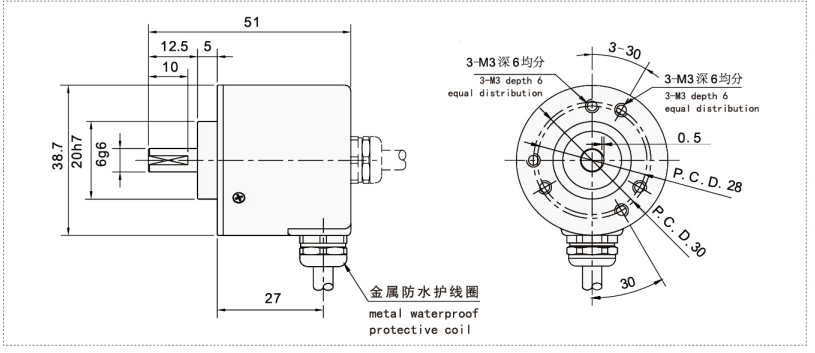

قطر مدمج 38 مم مع عمود صلب 6 مم لتركيب متعدد الاستخدامات

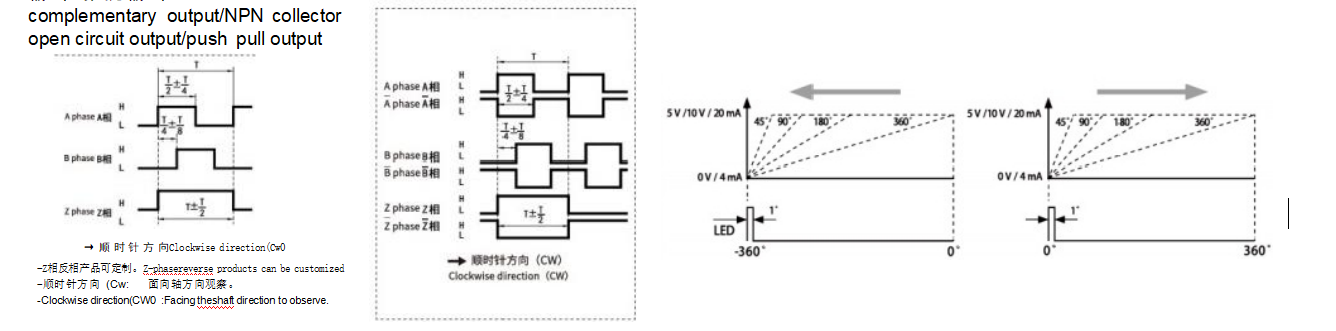

أنواع مخرجات متعددة: مجمّع مفتوح (NPN) ومخرجات دفع وسحب ومخرجات تكميلية

دائرة قوية مضادة للتداخل لإرسال إشارة مستقرة ومقاومة للتشويش

نطاق تشغيل واسع للجهد (عادةً 5-24 فولت تيار مستمر) مناسب لمعظم أنظمة التحكم الصناعية

متانة ميكانيكية عالية وغطاء مصنف IP لمقاومة الغبار والماء

متوافق مع مختلف أجهزة التحكم المنطق المنطقية القابلة للبرمجة (PLC) وأجهزة التحكم في السرعة

أطوال الكابلات الاختيارية وتكوينات الإخراج لتخصيص التركيبات

مزايا المنتج

تعمل الدقة والدقة العالية على تحسين دقة التحكم في الموضع والسرعة

تصميم متين وصغير الحجم يتحمل البيئات الصناعية الوعرة

تسمح إشارات الخرج المرنة بالتكامل مع أنظمة التحكم المختلفة

تصميم متقدم مضاد للتداخل يقلل من تشويش الإشارة ويعزز الموثوقية

يقلل التركيب السهل من وقت التعطل وجهود الصيانة

تدعم مجموعة كبيرة من الآلات الصناعية واحتياجات الأتمتة الصناعية

نموذج المنتج والمعنى

| G | 0 | S | 38 | B | 2500 | C | 3 | 2M | ||||

| فئة المنتج | نوع المنتج | شكل العمود الرئيسي | محيط المنتج | حجم العمود الرئيسي، فتحة العمود | المخرج و نموذج الختم | القرار | نموذج الإخراج | إشارة الإخراج | الكابل | |||

| ز: النوع الإضافي | س:ميجنيتو- الكهرباء ف:ضوئي- تريسيتي | S: عمود صلب | 38:φ38 مم | □: □ 6 مم 08:φ8 مم | ب: مخرج معدني جانبي د:معدن المخرج الخلفي | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1200,200,2048,2500,3000,3600,5000

| M: إخراج كمية تناظرية ج: خرج المجمع المفتوح و: الإخراج التكميلي ر: دفع سحب الإخراج L: خرج محرك الأقراص 5 فولت ج: خرج محرك 24 فولت | 1:إشارة المرحلة A 2:المرحلة AB إشارة 3:إشارة ABZ الطورية 4:ABA/B/إشارة 5: الطور ABZA/B/Z/إشارة ABZA/B/Z/ 6:420 مللي أمبير 7:0-5 فولت أمبير 8:0-10V | 2الافتراضي 2m خط،لأجل غير 2 م, الوسم هو كافية | |||

جدول الأسلاك

| لون الخط | إشارة الإخراج C/F/T | لون الخط | إشارة خرج L/A | لون الخط | إشارة M (تيار) | لون الخط | إشارة M (الجهد) | |||

| أحمر | في سي سي | أحمر | في سي سي | براون | في سي سي | براون | في سي سي | |||

| أسود | 0V | أسود | 0V | أبيض | 0V | أبيض | 0V | |||

| أخضر | أفيس | أخضر | أفيس | أخضر | 1 | أخضر | +U | |||

| أبيض | المرحلة ب | أبيض | المرحلة ب | أصفر | -1 | أصفر | -U | |||

| أصفر | المرحلة Z | أصفر | زفيز | الدرع | واو - زاي | الدرع | واو - زاي | |||

| الدرع | واو - زاي | بني | أ/المرحلة | |||||||

| رمادي | ب/المرحلة | |||||||||

| برتقالي | Z/المرحلة | |||||||||

| الدرع | واو - زاي |

فرق طور الإخراج

الرسومات الميكانيكية (مم)

سيناريوهات التطبيق

سرعة المحرك وملاحظات الموضع في الأتمتة الصناعية

مراقبة سرعة الحزام الناقل والتحكم فيها

مزامنة ماكينات التعبئة والتغليف وتشغيلها

استشعار موضع معدات CNC

الروبوتات لزاوية المفصل والتغذية المرتدة الدورانية

ماكينات الطباعة وأتمتة خط التجميع

التركيب والصيانة

تأكد من تطابق عمود أداة التشفير مع قطر اقتران التطبيق (عمود صلب 6 مم).

قم بمحاذاة عمود أداة التشفير بدقة مع عمود الماكينة؛ استخدم وصلات مرنة لتجنب إجهاد المحاذاة الخاطئة.

قم بتركيب أداة التشفير بإحكام باستخدام الأجهزة المرفقة لتقليل الاهتزاز.

قم بتوصيل مصدر الطاقة ضمن نطاق الجهد الموصى به (5-24 فولت تيار مستمر) باتباع مخطط الأسلاك.

استخدم كابلات محمية لأسلاك الإشارة لمنع التداخل الكهرومغناطيسي.

قم بالتنظيف المنتظم لإزالة الغبار والحطام؛ تجنب استخدام المواد الكيميائية القاسية أو نفاثات المياه.

افحص الأسلاك والموصلات بشكل دوري للتأكد من سلامة التوصيلات وسلامة الإشارة.

استبدل أداة التشفير إذا ظهرت علامات تآكل ميكانيكي أو إشارات غير مستقرة.

اطلب عرض أسعار الآن

سيقوم فريقنا بالرد عليك خلال 24 ساعة.