Capacitive proximity switches might sound like something out of a sci-fi movie, but they’re actually a game-changer in the world of automation and sensing technology. Whether you’re a tech enthusiast, an engineer, or just someone curious about how things work, this guide will break down everything you need to know about these fascinating devices. Ready to dive in? Let’s get started!

—

What is a Capacitive Proximity Switch?

A capacitive proximity switch is a type of sensor that detects the presence or absence of an object without physical contact. Think of it as a silent guardian that can “feel” objects nearby, even through barriers like plastic or glass. It’s like having a sixth sense for machines!

These switches are widely used in industries like manufacturing, automotive, and food processing. But what makes them so special? Let’s find out.

—

How Does a Capacitive Proximity Switch Work?

At its core, a capacitive proximity switch works by creating an electrostatic field. When an object enters this field, it changes the capacitance, triggering the switch. It’s similar to how your phone screen responds to your touch—except this is on a whole new level of precision.

The switch doesn’t care if the object is metal, plastic, or even liquid. As long as it has a dielectric constant, the switch can detect it. Pretty cool, right?

—

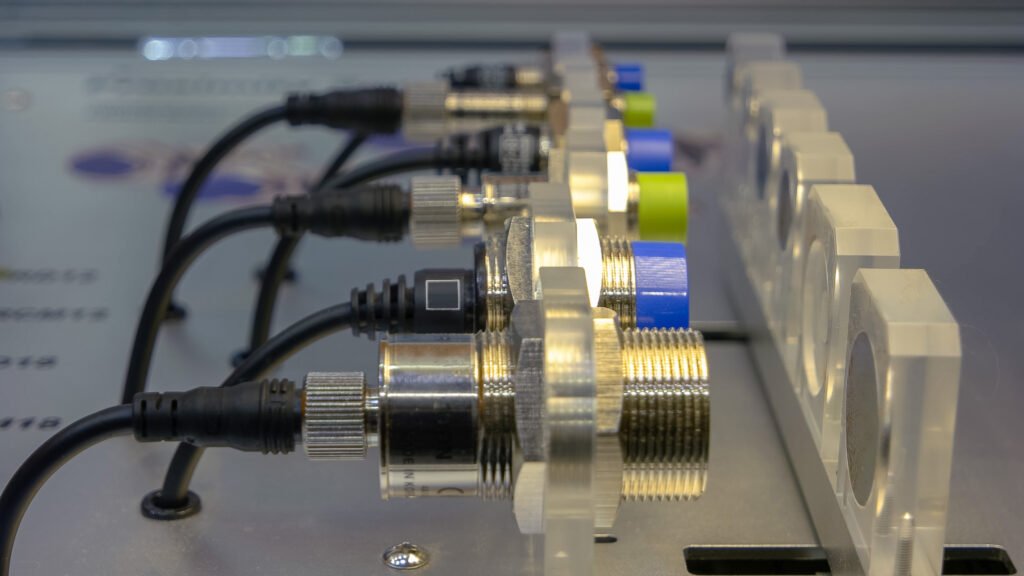

Key Components of a Capacitive Proximity Switch

Sensing Electrode

This is the heart of the switch. It generates the electrostatic field and detects changes in capacitance.

Oscillator Circuit

This component creates the high-frequency signal needed to generate the electrostatic field.

معالج الإشارات

Once the capacitance changes, the signal processor interprets the data and decides whether to trigger the switch.

Output Circuit

This is the final step, where the switch sends a signal to the connected system, like turning on a light or stopping a conveyor belt.

—

Types of Capacitive Proximity Switches

Standard Capacitive Switches

These are the most common type, ideal for general-purpose applications.

High-Temperature Capacitive Switches

Designed to withstand extreme heat, these are perfect for industries like metalworking.

Miniature Capacitive Switches

Compact and lightweight, these are used in tight spaces where size matters.

—

Applications of Capacitive Proximity Switches

From detecting liquid levels in tanks to ensuring packaging lines run smoothly, capacitive proximity switches are everywhere. They’re also used in touchscreens, vending machines, and even smart home devices.

—

Advantages of Using Capacitive Proximity Switches

Non-Contact Sensing:

Versatility:

المتانة:

—

Limitations of Capacitive Proximity Switches

While they’re amazing, they’re not perfect. They can be affected by environmental factors like humidity and temperature. Plus, they might struggle with very small objects or materials with low dielectric constants.

—

How to Choose the Right Capacitive Proximity Switch

Consider factors like sensing range, material compatibility, and environmental conditions. Don’t forget to check the IP rating for dust and water resistance!

—

نصائح التركيب والصيانة

Proper Alignment:

Regular Cleaning:

Routine Testing:

—

Future Trends in Capacitive Proximity Switch Technology

The future looks bright! Expect smarter switches with IoT integration, enhanced sensitivity, and even smaller designs. Imagine a world where these switches can communicate with each other in real-time—mind-blowing, right?

—

الخاتمة

Capacitive proximity switches are the unsung heroes of modern automation. They’re versatile, reliable, and incredibly efficient. Whether you’re using them in a factory or a futuristic smart home, these devices are here to make life easier. So, the next time you see a machine working seamlessly, remember—there’s probably a capacitive proximity switch behind the scenes.

—

الأسئلة الشائعة

What materials can a capacitive proximity switch detect?

Capacitive proximity switches can detect a wide range of materials, including metals, plastics, liquids, and even wood, as long as the material has a dielectric constant.

Can capacitive proximity switches work in harsh environments?

Yes! Many capacitive proximity switches are designed to withstand harsh conditions like dust, moisture, and extreme temperatures, thanks to their robust construction and high IP ratings.

How far can a capacitive proximity switch detect an object?

The sensing range varies depending on the model, but most switches can detect objects within a few millimeters to several centimeters.

Are capacitive proximity switches expensive?

While they might be slightly more expensive than other types of sensors, their durability and versatility often make them a cost-effective choice in the long run.

Can I use a capacitive proximity switch for liquid level detection?

Absolutely! Capacitive proximity switches are commonly used for liquid level detection in tanks and containers, making them a popular choice in industries like food processing and chemical manufacturing.