인코더 기호: 엔지니어링에서 인코더 기호를 이해하고 사용하기 위한 가이드

자동화, 로봇 공학 또는 산업 제어 시스템과 관련된 작업을 하다 보면 "인코더"라는 용어를 자주 접하게 됩니다. 하지만 기술 다이어그램에서 인코더 기호가 무엇을 의미하는지 궁금해하신 적이 있으신가요? 다음번에 인코더 기호를 볼 때 정확히 무엇을 보고 있는지, 왜 [...]인지 알 수 있도록 함께 분석해 보겠습니다.

자세히 보기

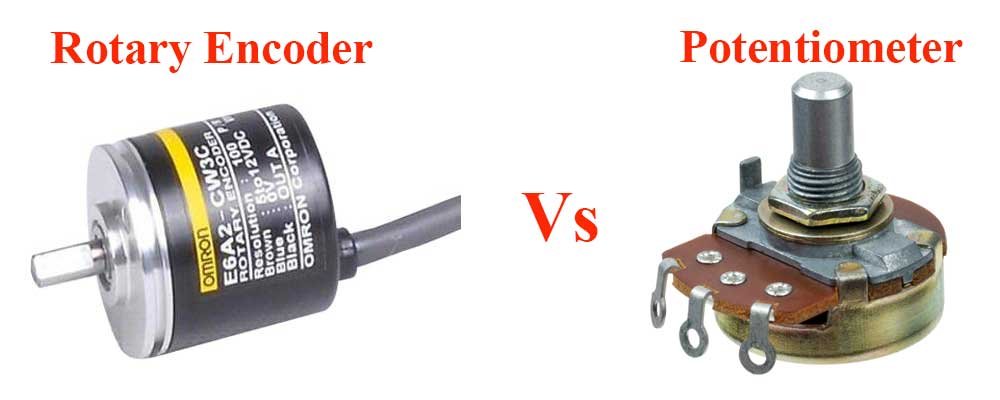

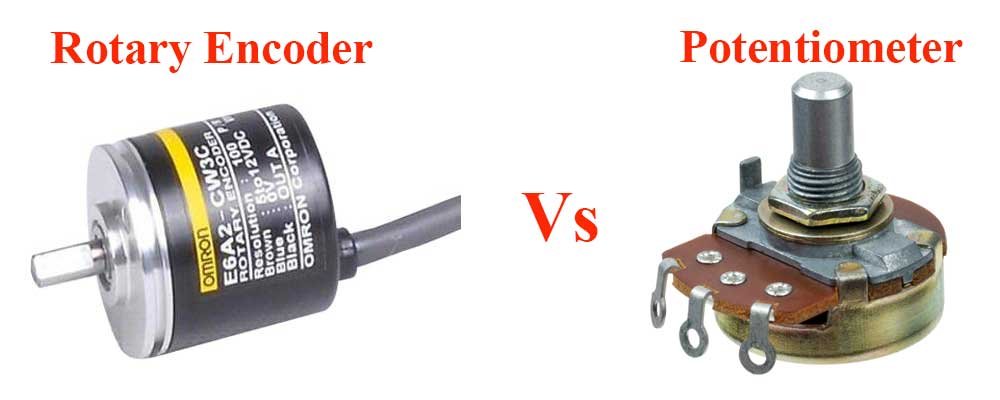

When you need to measure position or movement in automation, robotics, or industrial control, two names usually come up: encoder vs potentiometer.

While both serve a similar purpose—providing position feedback—their working principles, strengths, and ideal use cases are very different.

Let’s dig deeper into how these two popular sensors stack up so you can make a confident choice for your next project.

An encoder is a sensor that converts mechanical movement—whether rotation or linear travel—into digital signals.

It uses optical, magnetic, or capacitive technology to detect movement and outputs either pulses (incremental) or unique codes (absolute).

Encoders stand out for their high precision, reliability, and seamless integration with digital control systems.

You’ll find them in everything from industrial automation and robotics to CNC machines and advanced manufacturing setups.

Key advantages of encoders:

However, encoders do have a few considerations. Incremental encoders, for example, may require a homing procedure after power loss to re-establish position.

Some types can be sensitive to dust or oil contamination, especially optical models, but magnetic and capacitive designs are much more robust.

A potentiometer, or “pot,” is a much simpler device. It consists of a resistive track and a moving wiper.

As the wiper moves, it changes the resistance and produces an analog voltage that corresponds to position.

Potentiometers are widely used for basic position sensing in simple circuits, manual controls, and low-cost feedback systems.

Key advantages of potentiometers:

That said, potentiometers come with their own set of trade-offs. Because they rely on physical contact between the wiper and resistive track, they wear out over time.

They’re also more susceptible to dust, vibration, and electrical noise. If you need long-term reliability or high accuracy, these factors can become limiting.

| 기능 | 인코더 | Potentiometer |

|---|---|---|

| 출력 유형 | Digital pulses or codes | Analog voltage |

| Precision | High (especially optical types) | Moderate (limited by mechanical wear) |

| 내구성 | Long life (non-contact options) | Wears out over time (contact-based) |

| 비용 | Higher | Very low |

| Integration | Ideal for digital systems | Simple for analog circuits |

| Environmental Suitability | Robust (magnetic/capacitive types) | Sensitive to dust, vibration, wear |

| Power-on Behavior | May require homing (incremental type) | Always knows position |

| Application Focus | Precision, automation, robotics | Basic, low-cost feedback |

| 유지 관리 | Minimal (non-contact types) | Needs periodic replacement |

| 신호 안정성 | Stable, immune to analog drift | Can drift due to temperature or wear |

Choosing between an encoder and a potentiometer depends on your project’s requirements, budget, and environment.

Both encoders and potentiometers have their place in the world of position sensing.

Encoders excel in precision, digital compatibility, and long-term durability, making them the smart choice for advanced automation and demanding environments.

Potentiometers, on the other hand, offer simplicity and affordability for straightforward feedback needs.

Consider your project’s requirements, environment, and future scalability before making your choice.

The right sensor will keep your system running smoothly and accurately for years to come.