The GOS5006B Incremental Rotary Encoder is designed to deliver robust and dependable rotational feedback in a wide variety of machinery and systems. With its durable construction and versatile output options, this encoder ensures consistent performance even in challenging operational settings. Ideal for applications requiring accurate speed and position signals, the GOS5006B supports efficient motion monitoring and control functions.

Principais recursos:

High-resolution incremental output for consistent pulse signals

Heavy-duty construction with dustproof and vibration-resistant housing

Versatile output formats including TTL and open collector signals

Standard flange mounting and shaft coupling for hassle-free installation

Sealed enclosure and premium bearings ensure long operational life

Wide voltage operating range for flexible system compatibility

Vantagens do produto:

Delivers stable and reliable feedback to enhance system responsiveness

Heavy-duty design reduces downtime from equipment wear and harsh conditions

Simplifies integration with multiple output types and mounting options

Enhances machine performance by providing real-time motion data

Compact footprint allows use in space-sensitive environments

Product Model And Meaning

| G | 0 | S | 50 | 06 | B | – | 1000 | – | C | 3 | 2M | |

| Categoria de produto | Tipo de produto | Forma de eixo principal | Contorno de produto | Tamanho do principal eixo, furo do eixo | Saída e formulário de selagem | Resolução | Formulário de saída | Sinal de saída | Cabo | |||

| G:ncremental type | O:megneto- eletricidade | S: eixo sólido | 50:φ50mm | 06:φ6mm | B:Diagonal outlet | 10,20,50, 60,100, 200360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C: saída de coletor aberto F: saída complementar L:Saída de acionamento de 5V | 1:fase Asignal 2:sinal de fase AB 3:fase do sinal ABZ 4:fase Sinal ABA/B/ 5:fase do sinal ABZA/B/Z/ | Padrão 2m linha, para não 2m, A rotulagem é suficiente |

Tabela de fiação

Cor da linha | Sinal de saída C/F | – | Cor da linha | L/Aoutput signal |

| marrom | VCC | marrom | VCC | |

| azul | GND | |||

| azul | GND | |||

| preto | Uma fase | |||

| preto | Uma fase | branco | Fase B | |

| laranja | Fase Z | |||

| branco | Fase B | |||

| preto vermelho | Fase | |||

| laranja | Fase Z | branco vermelho | Fase B | |

| vermelho alaranjado | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

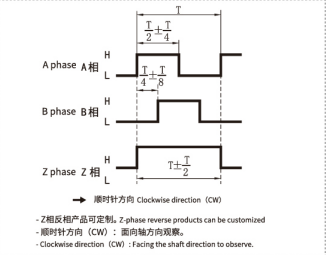

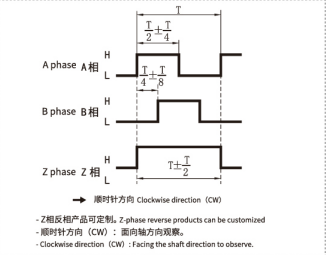

Output Phase Difference

saída complementar/saída de circuito aberto de coletor NPN

saída de acionamento de linha longa

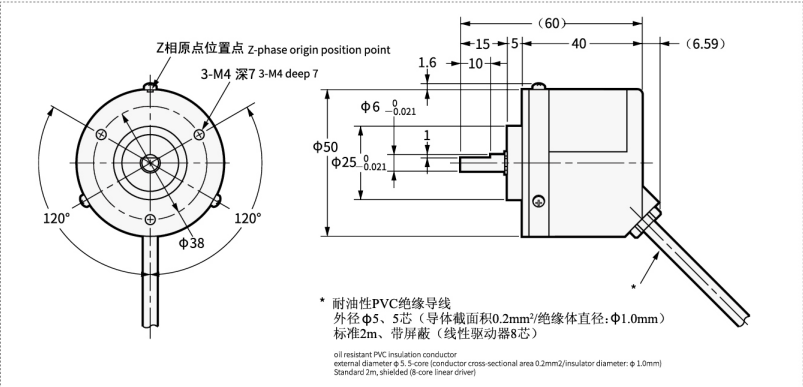

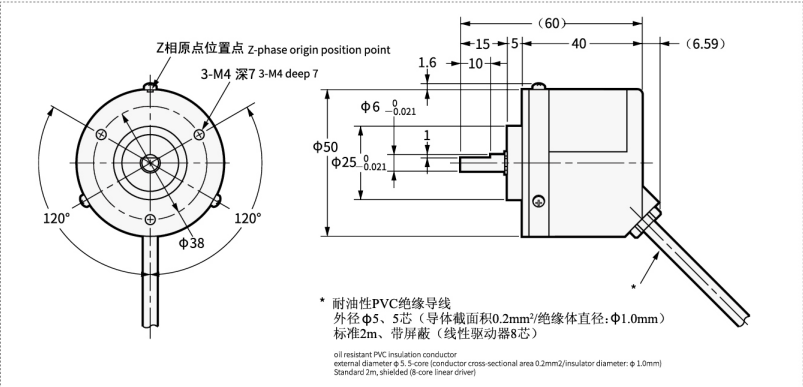

Desenhos mecânicos (mm)

Installation and Maintenance:

Mount the GOS5006B encoder securely onto the shaft using the provided coupling or adapter.

Align the encoder shaft precisely to avoid mechanical stress and ensure accurate signal output.

Connect the wiring according to the provided schematic, confirming voltage and signal correctness.

Test the encoder signals with your control or monitoring system before full deployment.

Periodically clean the encoder body to remove dirt and prevent buildup.

Check mounting hardware and connections regularly; perform lubrication if recommended.

Detailed Product Applications:

The GOS5006B encoder is suited for a broad spectrum of machinery and applications, including:

Conveyor belts and material handling systems requiring speed and position monitoring

Robotics and automated equipment needing consistent motion feedback

Packaging and printing machinery synchronization

Elevators, escalators, and lifts for smooth motion control and safety monitoring

Renewable energy systems such as wind turbines for rotational position feedback

Agricultural and construction equipment requiring rugged and reliable encoders

Medical diagnostic and treatment machinery demanding consistent operational data