Description

The COP-21R controller is a handheld industrial device engineered to provide dependable directional control for various machinery, including electric hoists, cranes, conveyors, and automated systems. Its two-button layout simplifies command inputs, enhancing operator safety and accuracy. Constructed with a waterproof and anti-oil ABS body, this control box resists dust, moisture, and industrial contaminants, making it suitable for outdoor and heavy-duty factory environments. With compatibility for 380V systems and a yellow ergonomic handle for comfort and safety, the COP-21R optimizes operational efficiency and reduces accident risks in industrial settings.

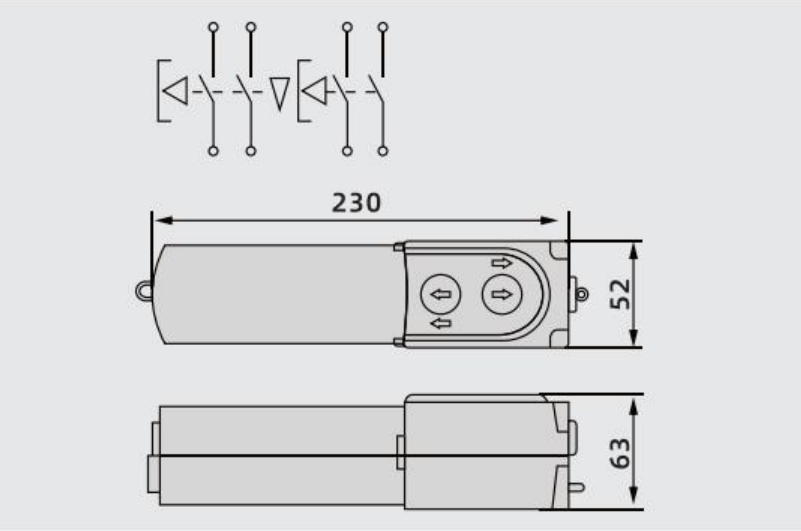

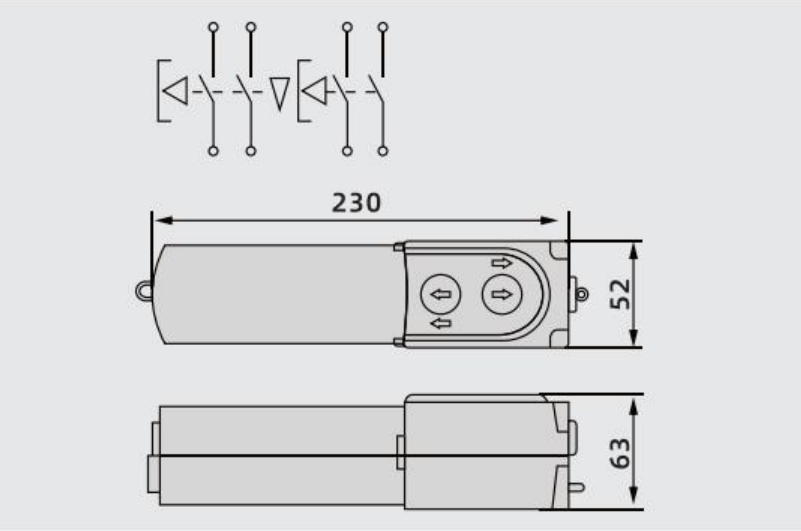

| Parameter | Specification |

|---|---|

| Model | COP-21R |

| Button Type | Push lock with capacitor |

| Number of Buttons | Two ON buttons |

| Capacitor Values | 1 µF, 30 µF, 40 µF, 50 µF (customizable) |

| Rated Insulation Voltage (Ui) | 500V |

| Rated Thermal Current (Ith) | 2A |

| AC-15 Contact Rating | 250V, 5A |

| Dimensions (L x W x H) | 230 mm x 52 mm x 63 mm |

Key Features

Durable ABS housing for water, oil, and dust resistance

Bright yellow ergonomic handle for easy identification and comfortable grip

Two-button layout for simple up/down directional control

Compatible with 380V electric hoists and industrial machinery

Compact handheld design ensures portability and ease of use

Reliable switch components designed for heavy-duty industrial environments

Safety certifications ensuring compliance with industrial standards

Product Advantages

Enhances operator safety by minimizing risks during equipment operation

Resistant to harsh industrial conditions, extending product lifespan

Improves operational precision with tactile, easy-to-use controls

Reduces downtime by enabling quick, responsive machine control

Portable and lightweight for flexible use across different workstations

Supports energy-efficient and optimized equipment performance through precise control

Complies with safety regulations and reduces workplace accidents

Installation Steps and Maintenance

Ensure the power to the connected machine is turned off before installation.

Mount the controller securely using the designated fixing points or attach it to the operator’s position for handheld use.

Connect wiring according to the electrical diagram, ensuring all terminals are firmly secured and insulated.

Test the button functions without load to confirm proper signal transmission.

Power on the machine and perform operational tests with load while maintaining safety precautions.

For maintenance, regularly inspect the controller for damage, wear, or contamination.

Clean the surface with a dry cloth; avoid water pressure or chemical cleaners to maintain waterproof integrity.

Replace worn or malfunctioning buttons immediately to ensure operational safety.

Product Applications

The COP-21R Handheld Industrial Direction Controller is highly versatile and can be applied across a broad range of industrial scenarios requiring reliable and precise directional control. Its robust design and two-button interface make it ideal for the following applications:

Cranes and Hoists Control: Primarily used for up/down and directional control in electric hoists and overhead cranes in factories, construction sites, and warehouses. It enables operators to safely maneuver heavy loads with tactile feedback and ergonomic handling.

Industrial Conveyor Systems: Facilitates directional control of conveyor belts used in manufacturing assembly lines, packaging plants, and material handling systems. The controller ensures smooth and accurate operation of equipment for loading, unloading, and transferring goods.

Automated and Robotic Equipment: Suitable for manual override and directional commands in automated production lines, robotic arms, and CNC machinery, enhancing safety by providing direct human control when needed.

Construction and Heavy Machinery: Ideal for operating machinery such as concrete pumps, lifts, and other mobile construction equipment where precise directional control is crucial for safety and efficiency.

Material Handling Equipment: Can be integrated with forklifts, stackers, and pallet jacks for intuitive manual directional inputs that improve maneuverability in tight spaces and busy warehouses.

Manufacturing and Assembly Lines: Used in assembly processes requiring manual directional inputs or movement of parts and equipment to specific stations or positions.

Agricultural and Mining Equipment: Adapted for durable outdoor use in controlling directional movements of specialized machinery in harsh environments such as mining drills or agricultural machinery.

Energy and Utility Systems: Operates mechanical components in energy plants, such as valves, pumps, and hoist mechanisms, supporting maintenance and emergency controls.

Safety Critical Systems: Because of its simple yet effective control layout with safety-certified components, it is commonly used in environments where quick and reliable emergency stop or directional control is vital to protect personnel and equipment.

Overall, the COP-21R controller is suited for industrial remote controls, heavy-duty directional switches, and manual machine control where durability, reliability, and safety compliance are paramount. Its long-lasting construction and ergonomic design support demanding industrial operations across sectors such as manufacturing, logistics, construction, energy, and automation.

Request a Quote Now

Our team will get back to you within 24 hours.