يوفر أداة التشفير الدوارة GLS50H تغذية راجعة دورانية موثوقة ومتسقة مصممة لتطبيقات الماكينات والأتمتة الصعبة. صُممت أداة التشفير هذه بهيكل قوي وخيارات إخراج متعددة الاستخدامات، وتوفر إشارات مستقرة للسرعة والموضع لدعم تتبع الحركة السلس وكفاءة النظام. تصميمه المتين وسهولة تركيبه يجعله مناسبًا لمجموعة كبيرة من البيئات الصناعية.

الميزات الرئيسية:

خرج تزايدي عالي الدقة ينتج إشارات نبضية مستقرة

حاوية متينة محكمة الغلق تحمي من الغبار والرطوبة والاهتزازات

يدعم تنسيقات إخراج TTL والمُجمِّع المفتوح للتكامل المرن

تركيب الشفة القياسية واقتران العمود لسهولة التركيب

محامل ممتازة تضمن عمر تشغيلي أطول

يتكيف نطاق إدخال الجهد العريض مع متطلبات إمداد الطاقة المتنوعة

مزايا المنتج:

يوفر تغذية راجعة موثوقة وثابتة للحركة لتعزيز الاتساق التشغيلي

تصميم شديد التحمل يقلل من وقت التعطل، حتى في البيئات القاسية

تعمل خيارات الإخراج والتركيب المرنة على تبسيط تكامل النظام

حجم صغير الحجم يسمح بالتركيب في التطبيقات محدودة المساحة

تعمل متطلبات الصيانة المنخفضة على تحسين وقت تشغيل النظام بشكل عام

نموذج المنتج والمعنى

| G | L | S | 50 | □ | H | 1000 | T | 3 | 2M | ||||

| فئة المنتج | نوع المنتج | شكل العمود الرئيسي | محيط المنتج | حجم الرئيسي العمود، فتحة العمود | المخرج و نموذج الختم | القرار | نموذج الإخراج | إشارة الإخراج | الكابل | ||||

| ز: النوع الإضافي | ل:فوتوويليك- تريسيتي | S:عمود صلب | 50:φ50 مم | □ □: Φ8 مم | ح:بلاستيك المخرج الخلفي | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | ج: خرج المجمع المفتوح T: دفع وسحب الخرج L: 5 فولت خرج محرك 5 فولت ج: خرج محرك 24 فولت | 1:إشارة المرحلة A 2:المرحلة AB إشارة 3:إشارة ABZ الطورية 4:مرحلة ABA/B/إشارة 4:4 6:الطور ABZA/B/Z/إشارة 6:6 | افتراضي 2m خط، لغير 2 م, التوسيم كافٍ | ||||

جدول الأسلاك

| لون الخط | إشارة الإخراج C/F/T | لون الخط | إشارة خرج L/A | |

| بني | VCC | بني | VCC | |

| أزرق | GND | |||

| أزرق | GND | |||

| أسود | المرحلة أ | |||

| البرقوق | المرحلة أ | أبيض | المرحلة ب | |

| النطاق | المرحلة Z | |||

| أبيض | المرحلة ب | |||

| أحمر | المرحلة أ | |||

| برتقالي | المرحلة Z | رمادي | بفاس | |

| أصفر | المرحلة Z | |||

| الدرع | واو - زاي | |||

| الدرع | واو - زاي |

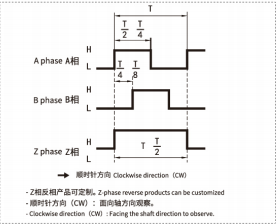

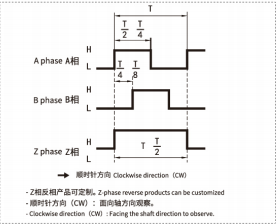

فرق طور الإخراج

المخرجات التكميلية/خرج الدائرة المفتوحة لمُجمِّع NPN

مخرجات محرك الخط الطويل

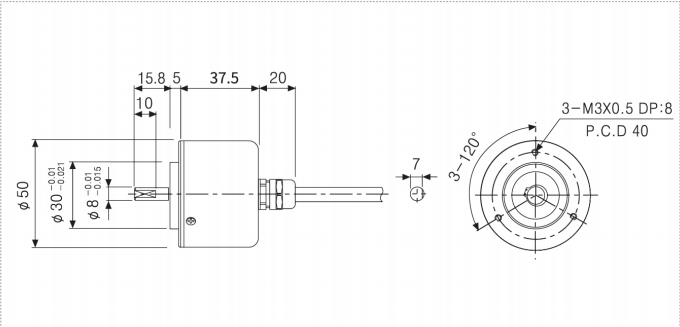

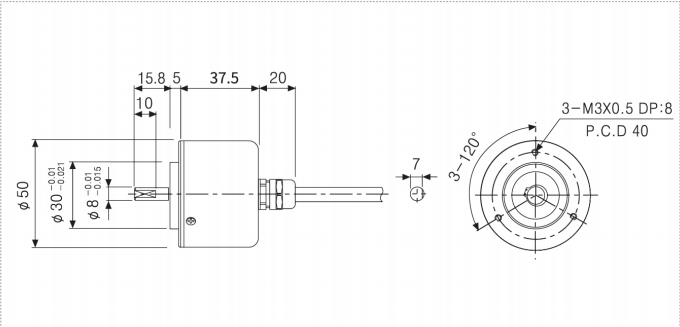

الرسومات الميكانيكية (مم)

التركيب والصيانة:

قم بتركيب أداة التشفير GLS50H بإحكام على العمود باستخدام الوصلة أو المحول المرفق.

تأكد من محاذاة العمود بشكل صحيح لتجنب الإجهاد الميكانيكي والقراءات غير الدقيقة.

قم بتوصيل الأسلاك بدقة وفقًا للمخطط المرفق، مع التحقق من الطاقة والإشارات الصحيحة.

قم بإجراء اختبار لإشارات الخرج مع نظام التحكم الخاص بك قبل النشر الكامل.

نظف جسم أداة التشفير بانتظام لمنع تراكم الغبار والحطام.

افحص الأجهزة والوصلات بشكل دوري؛ قم بتشحيم المحامل على النحو الموصى به.

تطبيقات المنتج التفصيلية:

جهاز التشفير GLS50H مناسب لمجموعة متنوعة من التطبيقات، بما في ذلك:

أنظمة الناقل ومناولة المواد ومراقبة السرعة والموقع

معدات الروبوتات والأتمتة التي تتطلب إشارات حركة موثوقة

ماكينات التعبئة والتغليف والطباعة لمزامنة العملية

مصاعد، وسلالم متحركة، ومصاعد كهربائية، ومصاعد كهربائية لمراقبة الأعمدة بسلاسة وأمان

أنظمة الطاقة المتجددة مثل توربينات الرياح للتغذية المرتدة لموضع الشفرة

الآلات الزراعية والمعدات الثقيلة في البيئات الصعبة

المعدات الطبية والمخبرية التي تتطلب استشعار دوران يمكن الاعتماد عليه

تُعد أجهزة التشفير الدوارة مثل GLS50H من المكونات المهمة في تعزيز موثوقية التغذية المرتدة للحركة عبر الأنظمة الآلية والميكانيكية. تركز التطورات في تقنية أداة التشفير على تحسين المقاومة البيئية وسلامة الإشارة لضمان التشغيل المستمر في الظروف الصعبة. تؤثر تقنيات التركيب المناسبة، بما في ذلك المحاذاة ودقة الأسلاك، بشكل كبير على طول عمر المشفر وأدائه. يتيح تكامل أجهزة التشفير مع منصات التحكم الرقمية الحديثة أيضًا الصيانة التنبؤية وتشخيص النظام، مما يمهد الطريق لعمليات أكثر ذكاءً وكفاءة للماكينات.