The GLT38B Incremental Rotary Encoder offers high accuracy and reliable performance tailored for industrial automation and motion control systems. Designed with robust construction, this rotary encoder provides stable signal output and easy installation, making it an ideal choice for various machinery, robotics, and manufacturing equipment.

Caractéristiques principales :

Precise incremental output with high-resolution pulse signals

Durable and compact design resistant to harsh industrial environments

Multiple output signal formats for versatile integration

Easy to install with standardized mounting options

Long service life with maintenance-friendly components

Compatible with various power supplies and control systems

Avantages du produit :

Ensures accurate speed and position feedback for enhanced control

Increases operational efficiency and reduces downtime

Robust build minimizes failure risk, ensuring continuous operation

Versatile use in diverse industrial applications including robotics, conveyors, and CNC machines

Supports extended cable lengths for flexible system design

Modèle de produit et signification

| G | O | H | 38 | A | 02 | 1000 | T | 3 | 2M | ||||

| Catégorie de produit | Type de produit | Forme de arbre principal | Contour de la produit | Taille de l'arbre principal, trou de l'arbre | Outlet and formulaire de scellement | Aperçu structure | Résolution | Formulaire de sortie | Signal de sortie | Câble | |||

| G:incrémental type | 0:megneto- électricité | H:semi- arbre creux | 38:φ38mm | □:φ8mm | A:fil de caoutchouc protecton manchon | 02:2 outline structure2 | 10,20,50, 60,100, 200360, 400,500, 600800, 1000,1024, 1200,2000, 2048,2500, 3000,3600, 4096等 | T:sortie push pull L:Sortie d'entraînement 5V A:Sortie d'entraînement 24V | 1:phase Asignal 2:signal de phase AB 3:phase signal ABZ 4:phase ABA/B/ signal 5:phase ABZA/B/Z/ signal | Défaut 2m ligne, pour non 2m, L'étiquetage est suffisant | |||

Tableau de câblage

| Couleur de la ligne | Signal de sortie C/F | – | Couleur de la ligne | Signal de sortie |

| brun | VCC | brun | VCC | |

| bleu | GND | |||

| bleu | GND | |||

| noir | Une phase | |||

| noir | Une phase | blanc | Phase B | |

| orange | Phase Z | |||

| blanc | Phase B | |||

| purple | Aphase | |||

| orange | Phase Z | gris | Bphase | |

| jaune | Phase Z | |||

| bouclier | F -G | |||

| bouclier | F -G |

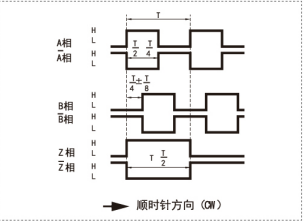

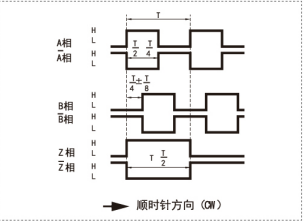

Output Phase Difference

push pull output

long line drive output

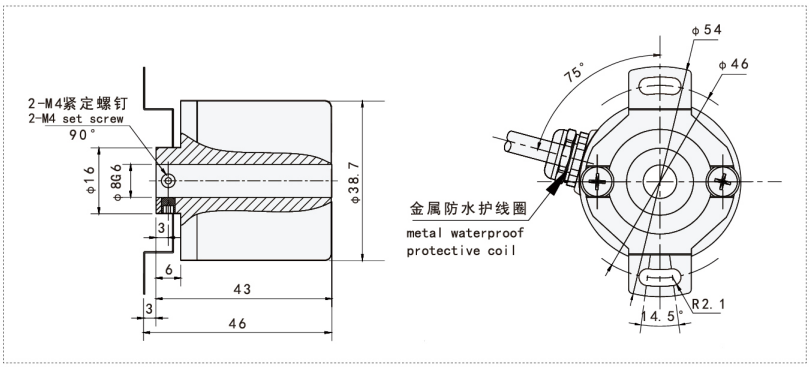

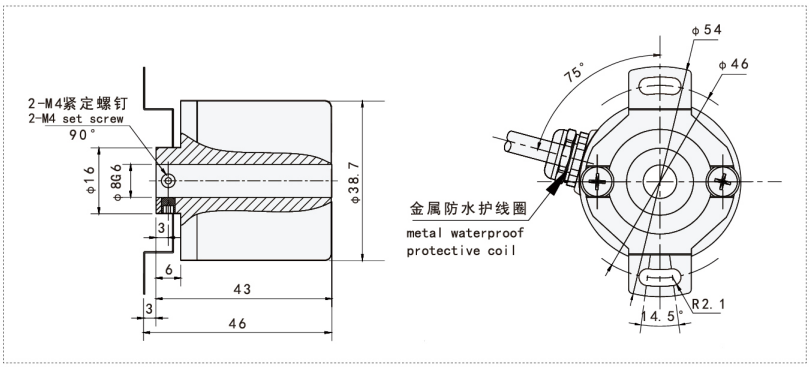

Mechanical Drawings(mm)

Installation and Maintenance Steps:

Secure the GLT38B encoder to the mounting shaft using the provided coupling or adapter.

Align the encoder carefully to prevent shaft misalignment and potential signal errors.

Connect the encoder wiring according to the wiring diagram, ensuring correct power and signal connections.

Test the output signals with your control system to confirm proper operation.

For maintenance, regularly inspect for dust or debris buildup and clean the encoder body gently.

Check for loose connections or wear on mechanical couplings during periodic inspections.

Applications des produits

The GLT38B Incremental Rotary Encoder is highly versatile and widely used across various industries for precise motion control and monitoring tasks. Its reliable performance and robust design make it suitable for a broad range of applications, including but not limited to:

Automatisation industrielle :

Integral for feedback systems in automated production lines, robotics arms, and assembly machinery, providing accurate position and speed data to optimize processes and ensure product quality.Robotics and Automated Guided Vehicles (AGVs):

Essential for navigation, positioning, and speed control in robotic applications and AGVs, enhancing movement precision and operational safety in warehouses and manufacturing facilities.Computer Numerical Control (CNC) Machines:

Provides real-time position feedback on milling, drilling, and turning machines, enabling high-precision machining and improved accuracy of manufactured parts.Conveyor and Material Handling Systems:

Monitors speed and position of conveyor belts and other material handling equipment, ensuring smooth operation and synchronized workflow in logistics, packaging, and assembly.Printing and Packaging Machinery:

Controls the motion of printing rollers, feeders, and packaging lines to guarantee consistent output speed and precise material handling, reducing errors and waste.Renewable Energy Systems:

Used in wind turbine and solar tracking systems to measure rotational position and optimize energy capture efficiency.Elevators and Escalators:

Provides feedback for smooth and safe operation by tracking shaft rotation and position, enhancing safety protocols and ride comfort.Medical Equipment:

Applied in devices like MRI machines and robotic surgical tools, where precise motion control is critical.Textile Machinery:

Ensures accurate control of fabric feed and machine operations for consistent product quality.

The versatility, accuracy, and ruggedness of the GLT38B Incremental Rotary Encoder make it a preferred choice in any application that demands reliable rotational position sensing and speed feedback.