Dust-Proof, Oil-Tolerant, Harsh-Environment Magnetic Rotary Encoder

목차

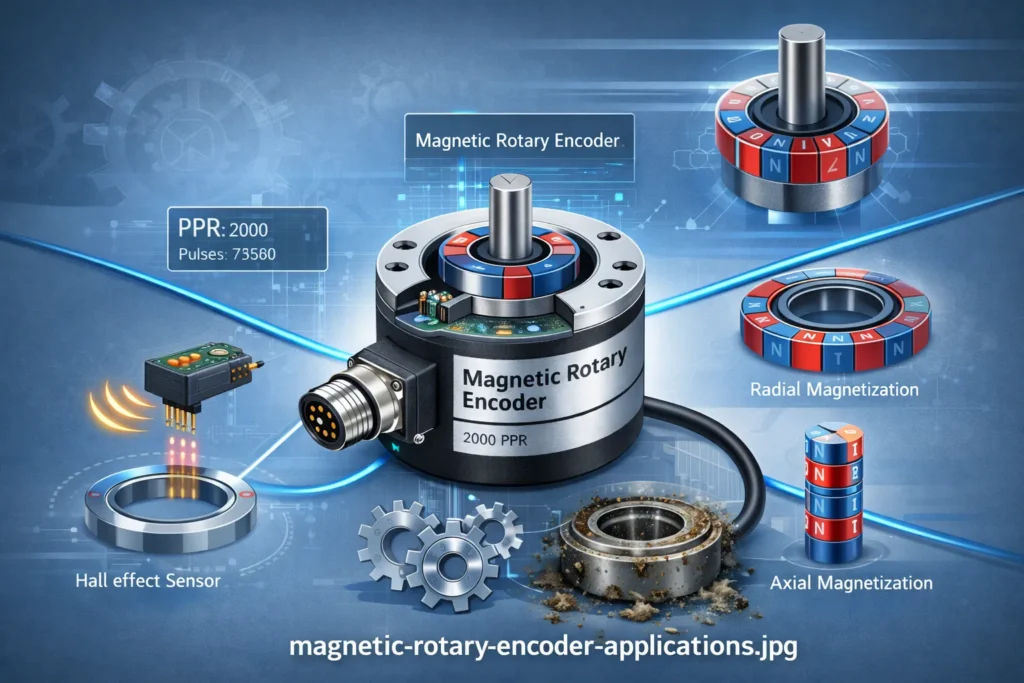

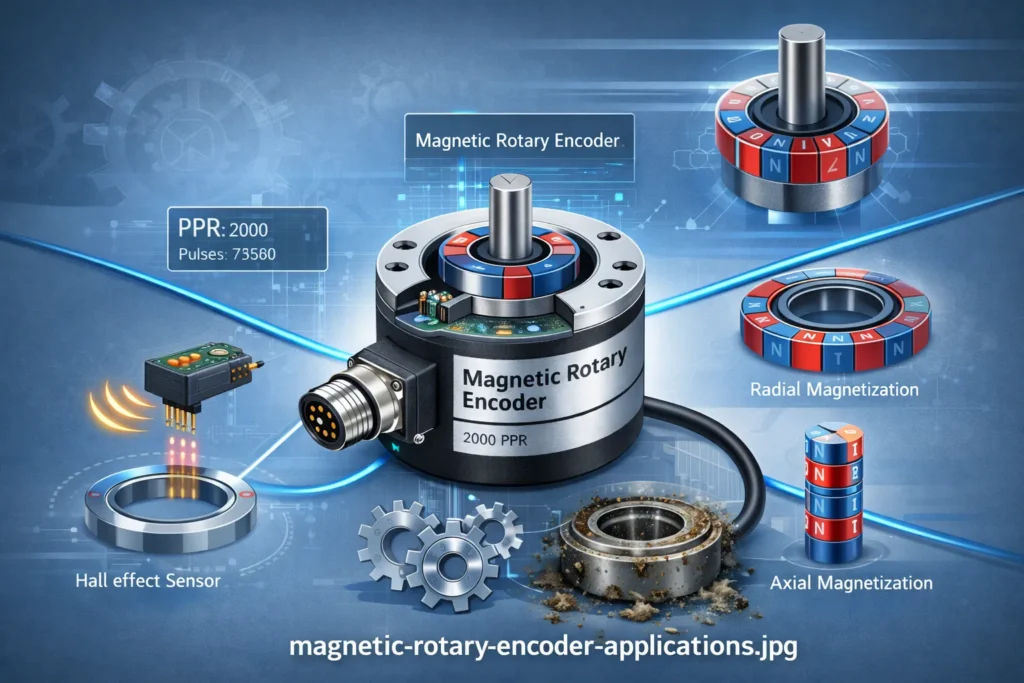

When reliability meets tough conditions, our magnetic rotary encoder is your go-to solution. Utilizing advanced Hall effect, AMR-GMR-TMR sensors, and robust radial or axial magnetized rings, this non-contact rotary encoder delivers accurate and consistent 360° position feedback—even in the most demanding environments.

Unlike optical encoders, our dust-proof 그리고 oil-tolerant position sensor excels where dirt, moisture, vibration, and shock challenge performance. Designed for harsh environments, it maintains precision without wear, ensuring longer service life and lower maintenance costs.

Discover a contactless angle sensor built to withstand heavy dust, oil contamination, and industrial vibrations—perfect for industrial automation, heavy machinery, and outdoor applications.

Ready to upgrade your system?

[Get a Quote] | [View Models]

Key Features & Benefits of Magnetic Rotary Encoder

Our magnetic rotary encoder offers top-notch performance with features designed for harsh environments and reliable precision:

- Non-contact magnetic sensing: No physical wear means a longer lifespan and consistent accuracy.

- High tolerance to contaminants: Resistant to dust, oil, moisture, vibration, and shock—perfect for tough industrial settings.

- Wide temperature range: Operates smoothly from -40°C up to +125°C or beyond, ensuring stable performance in extreme heat or cold.

- Flexible mounting options: Choose between radial or axial magnetization, fitting your application needs easily.

- Output types:

- Incremental: A/B/Z quadrature signals for speed and position tracking.

- Absolute: Supports SSI, BiSS-C, SPI, and PWM interfaces for precise angle measurement.

- High resolution: Up to 14-bit or more for ultra-precise position feedback with low latency.

- Compact and easy to integrate: Available in hollow shaft and solid shaft styles to match your mechanical setup.

- Energy-efficient design: Low power consumption helps reduce system energy costs.

| 기능 | 혜택 |

|---|---|

| Non-contact sensing | Extended lifespan, no wear |

| Dust/oil/moisture resistant | Reliable in dirty, oily places |

| Wide operating temperature | Works in extreme climates |

| Radial & axial magnetization | Flexible installation |

| Incremental & absolute outputs | Versatile signal compatibility |

| High resolution (up to 14-bit) | Precise angle and speed data |

| Shaft options | Easy mechanical integration |

| Low power consumption | Energy-saving |

This combination of durability, flexibility, and precision makes our magnetic rotary encoder ideal for industries needing robust and long-lasting position feedback.

For related connectivity options, you can check out aviation connectors designed to complement these encoders for seamless integration.

How Magnetic Rotary Encoders Work

Magnetic rotary encoders use contactless magnetic sensing to track rotational position accurately. At the core, they rely on a magnetic rotary position sensor made up of advanced Hall effect, AMR, GMR, or TMR sensors. These sensors detect changes in the magnetic field generated by a nearby magnetized ring.

The magnetized ring can be designed with either radial or axial magnetization, depending on the mounting setup. Radial magnetization projects the magnetic field outward around the ring’s circumference, while axial magnetization points the field along the ring’s axis. The sensor picks up these magnetic fields, converting them into electrical signals that change as the shaft rotates.

Inside the encoder, sophisticated signal processing takes place to translate these magnetic variations into precise angle and speed data. This ensures reliable 360° position feedback with minimal latency, even in harsh environments affected by dust, oil, or vibration. Thanks to this technology, magnetic rotary encoders deliver accurate rotation measurements without wear, extending lifespan and reducing maintenance. For related hardware like connectors that support harsh conditions, check out our durable LD28 series aviation connector.

Why Choose Magnetic Over Optical Encoders?

Magnetic rotary encoders outperform optical encoders in many harsh environments. Here’s a quick comparison to show why magnetic encoders are often the better choice:

| 기능 | Magnetic Rotary Encoder | Optical Encoder |

|---|---|---|

| 내구성 | High – dust-proof, oil-tolerant | Low – sensitive to dirt & oil |

| Environmental Resistance | Excellent in vibration, moisture, shock | Moderate, prone to contamination |

| Air Gap Tolerance | Flexible, works with larger gaps | Requires precise, small gaps |

| 비용 | Generally lower total cost (less maintenance) | Higher initial & upkeep costs |

| 유지 관리 | Minimal, no cleaning needed | Regular cleaning required |

| Resolution & Accuracy | Up to 14-bit and suitable accuracy | Very high, but less robust |

Real-World Advantages of Magnetic Encoders

- 산업 자동화: Handle dusty factory floors and oily machinery with ease, providing precise angle and speed feedback.

- Outdoor Machinery: Work reliably under moisture, mud, and varying temperatures.

- Motors & Drives: Perfect for brushless DC motors and servo drives operating with vibrations and tough environments.

In , magnetic rotary position sensors offer rugged, long-lasting feedback solutions that optical encoders can’t match in demanding conditions. For projects that need both precision and durability, magnetic encoders are the smart choice.

Check out our durable magnetic rotary encoders with various output options and robust designs—perfect for tough industrial setups like those featured in our GOS5008A01 magnetic encoder.

Technical Specifications of Magnetic Rotary Encoder

Here’s a clear overview of the key technical specs for our magnetic rotary encoders, designed to meet tough industrial demands:

| 사양 | 세부 정보 |

|---|---|

| 해상도 | Up to 14-bit or higher (bits / PPR) |

| Accuracy | Typically ±0.1° to ±10 arcsec depending on model |

| Output Interfaces | SSI, BiSS-C, SPI, PWM, ABZ quadrature, Analog |

| 공급 전압 | 5 V to 24 V DC |

| Current Draw | Low power, typically under 30 mA |

| Max Rotational Speed | Up to 12,000 RPM or as per model |

| 보호 등급 | Industrial grade IP67, IP68, or IP69K |

| Shaft Options | Hollow shaft & solid shaft, various bore diameters |

| Magnetic Field Strength | Compatible with radial or axial magnetized rings (strength varies by ring type) |

| Operating Temperature | -40°C to +125°C (some units offer wider ranges) |

| Storage Temperature | -40°C to +125°C or wider |

| Vibration & Shock Resistance | Compliant with industrial standards (e.g., IEC 60068) |

Our magnetic rotary encoders deliver reliable non-contact angle sensing suited for harsh environments. The combination of Hall effect, AMR, GMR, and TMR sensor technology ensures precise position feedback even under dust, oil, and vibration stresses.

With flexible interface options and rugged IP ratings, these encoders integrate easily into industrial automation, outdoor machines, and motor control applications. The compact designs and various shaft configurations make installation straightforward for different setups.

For detailed layout and customizable options, check out the comprehensive specs on the product page or request a datasheet to see how the dust-proof magnetic encoder fits your needs.

Applications of Magnetic Rotary Encoder

Magnetic rotary encoders are ideal for tough environments where accuracy and durability matter. Their dust-proof, oil-tolerant, and harsh environment design makes them perfect for:

- Industrial automation & robotics: Providing precise position feedback for robot arms and automated machinery, even in dusty or oily factory floors.

- Motor commutation for BLDC 그리고 servo motors: Enabling smooth and accurate motor control with contactless angle sensors that handle vibration and heat.

- Heavy machinery & off-road vehicles: Offering reliable position sensing in construction equipment, mining trucks, and other rugged vehicles exposed to dirt and shock.

- Wind turbines & renewable energy: Delivering non-contact, high-resolution position feedback for rotor blades and yaw control in variable weather conditions.

- Agricultural equipment: Withstanding dust, mud, and moisture to ensure precise control in tractors, harvesters, and other farm machinery.

- Harsh environment position feedback: Essential in oil & gas and mining sectors where magnetic rotary position sensors resist contamination and physical wear.

These use cases highlight why magnetic encoders outperform optical sensors where harsh conditions demand longevity and reliability. If your application requires robust performance in challenging environments, magnetic rotary encoders are your go-to solution.

For further guidance on sensor types suitable for tough conditions, check out our detailed proximity switch sensors application guide.

Product Models / Variants

Wilmall offers a range of magnetic rotary encoders designed to fit various industrial needs. Here are some key series and models to consider:

- SD13 Series: Contactless hall effect rotary encoder with high durability, perfect for harsh environments. Offers incremental outputs with resolutions up to 14-bit and supports solid or hollow shaft options.

- GLS38A05: An incremental magnetic encoder optimized for industrial automation, featuring robust dust and oil tolerance, ideal for vibration-prone settings. It supports ABZ quadrature output and flexible shaft sizes.

- Custom Variants: Available in both radial and axial magnetization designs, supporting absolute outputs like SSI, BiSS-C, SPI, and PWM to meet diverse application demands.

| 모델 | 해상도 | 출력 유형 | Shaft Style |

|---|---|---|---|

| SD13 Series | Up to 14-bit | Incremental (ABZ) | Solid / Hollow |

| GLS38A05 | Up to 13-bit | Incremental (ABZ) | Solid / Hollow |

| Custom Models | Up to 16-bit+ | Absolute (SSI, BiSS) | Radial/Axial |

Pricing depends on model specifications and order volume. For tailored solutions or bulk orders, we encourage you to request a quote.

Explore our detailed options and technical details on our incremental rotary encoder page or check the robust GLS38A05 incremental encoder for industry-standard performance.

Feel free to contact us for custom magnetic rotary encoders matching your specific application requirements.

Mounting & Installation Guide for Magnetic Rotary Encoders

Proper mounting and installation are key to getting accurate feedback from your magnetic rotary encoder. Here’s what to keep in mind:

Recommended Air Gap & Alignment

- Maintain the specified air gap between the magnetic ring and the sensor (typically 0.5 to 2.5 mm) to ensure precise readings.

- Align the encoder sensor and the magnet ring carefully; misalignment can cause signal distortion or loss.

- Radial magnetization requires consistent concentric mounting, while axial magnetization demands precise axial alignment.

Magnet Ring Installation Tips

- Choose the right magnet ring type (radial or axial) based on your application and sensor model.

- Secure the magnet firmly to prevent movement; slight magnet shifts can impact accuracy.

- Avoid magnet contamination with dust or oil during installation to preserve signal quality.

Wiring Diagrams for Common Interfaces

- Follow recommended wiring practices for your encoder’s output type, such as SSI, BiSS-C, SPI, PWM, or incremental A/B/Z signals.

- Use shielded cables and proper grounding to minimize electrical noise, especially in harsh environments.

- Reference specific wiring guides for interface connections, ensuring power supply and signal lines meet your device’s specs.

Calibration & Zero-Position Setup

- After installation, perform calibration to set the zero or reference position. Calibration can be done manually or via software depending on the encoder model.

- Regular recalibration is advised if used in environments with vibration or temperature changes to maintain accuracy.

For detailed wiring instructions and practical tips on connector handling, check out our working principle of aviation connector page for compatible connection solutions.

Following these steps ensures your contactless magnetic rotary encoder will deliver reliable, precise position feedback even in the toughest conditions.

FAQs: Magnetic Rotary Encoder Common Questions

| Question | Answer |

|---|---|

| How does it handle oil and dust? | Thanks to contactless magnetic sensing with Hall effect / AMR-GMR-TMR sensors, these encoders resist oil, dust, moisture, and vibration much better than optical types. Their sealed design prevents contaminants from affecting accuracy or lifespan. |

| What’s the difference from optical encoders? | Magnetic rotary encoders use magnetic fields, making them more durable in harsh environments. Optical encoders rely on light and can fail if dust or oil blocks the optics. Magnetic ones also allow larger air gaps, reducing mounting concerns. |

| Can it work with my motor? | Most likely yes. They support common interfaces (SSI, BiSS-C, SPI, PWM, ABZ) and come in various shaft styles to fit BLDC, servo, and other motor types. Check your motor specs against our compatibility guides to be sure. |

| What output types are available? | Incremental (A/B/Z quadrature) and absolute (SSI, BiSS-C, SPI, PWM) outputs cover a wide range of control systems and applications. |

| What’s the max operating temperature? | These magnetic rotary position sensors generally operate reliably from around -40°C up to +125°C or even higher, depending on the model. |

| Is it easy to install? | Yes. With options for radial or axial magnet rings and detailed mounting instructions, installation is straightforward. Wiring guides simplify connection for your control system. |

Got more questions? Feel free to reach out or check out related installation tips for magnetic sensors on our site. For detailed connection info, our industrial remote control transmitter guide is a useful resource for understanding signal management in harsh environments.

Resources & Downloads

Access all the essential resources you need for your magnetic rotary encoder right here. Download detailed datasheets, CAD models, and 3D files to help with your design and integration process. Our user manuals and installation videos make setup straightforward, whether you’re working with Hall effect rotary encoders or advanced AMR-GMR-TMR sensor-based devices.

Explore related products like durable magnetic rings and accessories to complement your non-contact rotary encoder system. These tools ensure you get the best from your dust-proof, oil-tolerant, harsh environment magnetic rotary encoder.

For easy sourcing of compatible parts, check out our range of high-quality products such as the GOS50C series magnetic rotary encoders and robust cable glands designed for tough installations.

Why Wilmall?

Choosing Wilmall means you get reliable quality magnetic rotary encoders designed to perform in harsh environments. Our products are dust-proof, oil-tolerant, and built to last, offering exceptional durability compared to optical encoders. With competitive pricing and fast customization options, we make it easy to find the right contactless angle sensor or absolute magnetic encoder that fits your specific needs.

We back our magnetic rotary position sensors and hall effect rotary encoders with expert support tailored for industrial applications, including heavy machinery, robotics, and renewable energy sectors. From radial magnetization encoders to axial magnetization sensors, Wilmall ensures you have the best tech combined with knowledgeable service.

Ready to experience precision without compromise? Contact us for custom solutions or request a sample today and discover why Wilmall is the trusted partner for reliable, harsh environment rotary encoders. For more insights on rotary encoder technology, visit our comprehensive rotary encoder guide.