The GOS50C incremental rotary encoder is built for robust performance in heavy-duty industrial automation applications. Featuring a sturdy 50mm flange diameter with an 8mm solid shaft, this encoder provides precise rotational position and speed feedback with pulse resolutions ranging up to 5000 PPR. Designed with enhanced protection against dust and moderate moisture, the GOS50C is ideal for environments with challenging operating conditions. Its multiple output formats, including push-pull and open collector, offer flexible integration with Siemens PLCs and other automation control systems.

주요 기능

Incremental rotary encoder with resolution options from 10 to 5000 pulses per revolution

Sturdy 50mm flange housing for reliable mounting stability

8mm solid shaft designed for heavy-duty rotary equipment

Supports output signals: push-pull, open collector, and line driver types

Wide supply voltage range of 5V to 30V DC for versatile system compatibility

Dust-resistant enclosure suitable for industrial factory floors

Precise phase difference outputs (A, B, Z signals and their complements) for accurate position detection

Designed to withstand high shaft shock and vibration loads

제품 이점

Robust mechanical construction suited for continuous industrial use

Versatile resolution and output options allow custom configuration for multiple applications

Compatible with Siemens PLCs and other major industrial control systems

High tolerance to mechanical shock and vibration reduces breakdown risks

Reliable signal output ensures precise control and monitoring of motors, conveyors, and coiling equipment

Easy to install with straightforward wiring and connection

제품 모델 및 의미

| G | 0 | S | 50 | □ | C | 1000 | T | 3 | 2M | |||

| 카테고리 제품 | 유형 제품 | 형태 메인 샤프트 | 컨투어 제품 | 메인 크기 샤프트, 샤프트 구멍

| 아울렛 및 씰링 양식 | 해상도 | 출력 양식 | 출력 신호 | 케이블 | |||

| G:incremental type | O:megneto- 전기 L: photoelec– 트라이시티 | S:solid shaft | 50:φ50mm | □:Φ8mm

| C:rear-outlet rubber | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096

| T: push pull output L: 5V drive output A: 24V drive output | 1:위상 신호 2:위상 AB 신호 3:위상 ABZ 신호 4:위상 ABA/B/ 신호 5:위상 ABZA/B/Z/ 신호 | 기본값 2m line,For non 2m, labeling is sufficient |

배선 테이블

| 선 색상 | Toutput signal | 선 색상 | L/A output signal | |

| 빨간색 | VCC | 빨간색 | VCC | |

| 검은색 | GND | |||

| 검은색 | GND | |||

| 녹색 | 단계 | |||

| 녹색 | 단계 | 흰색 | B 단계 | |

| 노란색 | Z 단계 | |||

| 흰색 | B 단계 | |||

| blue black | Aphase | |||

| 노란색 | Z 단계 | white black | B단계 | |

| yellow black | Zphase | |||

| 방패 | F -G | |||

| 방패 | F -G |

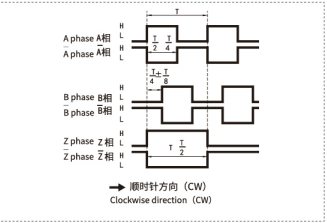

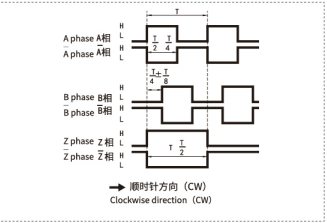

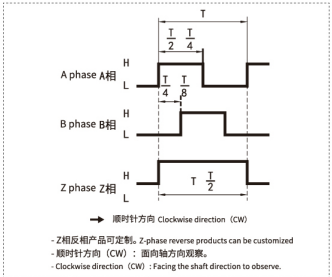

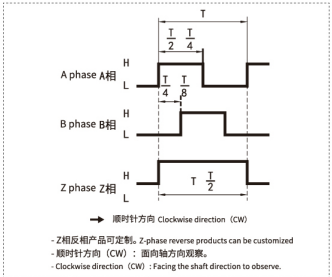

출력 위상차

보완적 출력/푸시 풀 출력/NPN 콜렉터 개방 회로 출력

롱라인 드라이브 출력

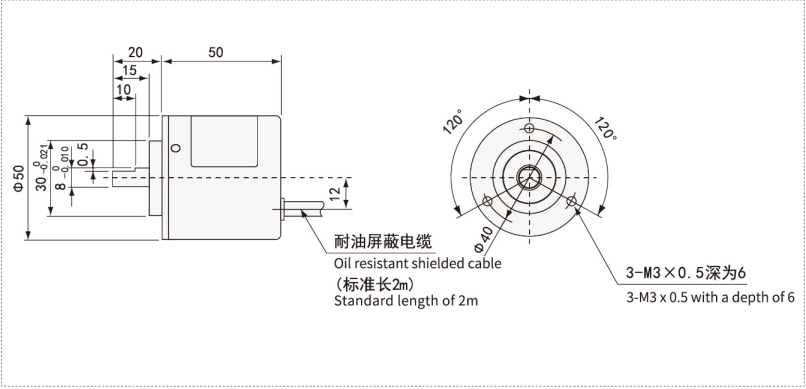

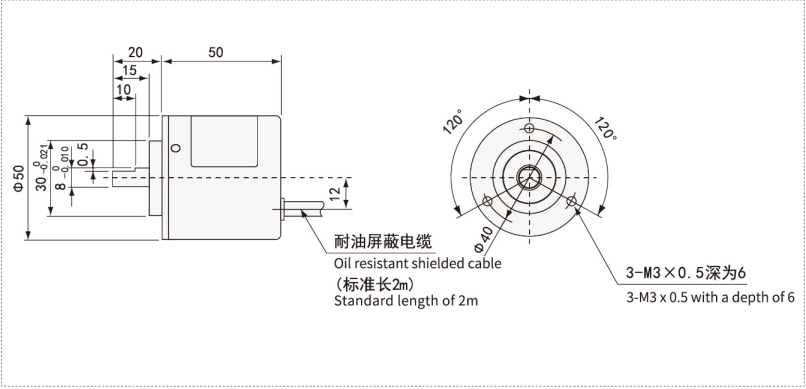

기계 도면(mm)

애플리케이션 시나리오

Heavy-duty coiling and rolling machines requiring accurate speed and position control

Conveyor belt systems in manufacturing plants with PLC automation

Industrial motor feedback for precise speed regulation

Automation systems utilizing Siemens PLCs and similar controllers

Packaging machines and material handling equipment

Robotics and mechanical handling applications requiring reliable rotary position feedback

설치 및 유지 관리

Verify that the mounting flange and 8mm shaft match the intended application equipment.

Carefully align the encoder shaft to prevent mechanical stress and premature wear; use flexible couplings if necessary.

Securely fasten the encoder with mounting screws to minimize vibrations.

Connect power supply (5-30V DC) observing polarity and follow wiring diagrams for the chosen output signals.

Employ shielded cables for output signals to avoid electromagnetic interference in industrial environments.

Regularly check for dust accumulation and clean the encoder surface gently as needed.

Periodically inspect wiring connections to avoid loose contacts.

Replace the encoder if abnormal signal behavior or mechanical damage occurs.

지금 견적 요청하기

저희 팀이 24시간 이내에 연락을 드릴 것입니다.