The GOS38A02 incremental rotary encoder is designed for precision motion control in industrial automation applications. Featuring a compact 38mm diameter and semi-hollow shaft, it delivers accurate position and speed feedback with resolutions up to 10,000 pulses per revolution. Its robust IP65-rated construction guarantees reliable performance in harsh environments. Compatible with various PLCs and control systems, the GOS38A02 offers versatile output signals including open collector, push-pull, and line driver, ensuring seamless integration in conveyor, robotics, CNC, and packaging machines.

Key Features

Incremental optical rotary encoder with high-resolution options from 100 to 10,000 PPR

Semi-hollow shaft design (typically 8mm diameter) for direct motor installation and easy coupling

IP65-rated housing protects against dust and water ingress for industrial durability

Wide DC input voltage range from 5 to 24V for flexible system compatibility

Multiple output signal types: open collector (NPN), complementary push-pull, and 5V line driver differential signals

Anti-interference circuitry for stable, noise-resistant signal output

Compact 38mm outer diameter facilitating integration in tight mechanical assemblies

Long cable options with protective rubber sleeves available

Product Advantages

High-resolution measurement enabling precise speed and position control

Semi-hollow shaft supports easier installation and shaft alignment

Robust IP65 protection increases encoder longevity in tough environments

Versatile outputs support a wide range of industrial control applications

Enhanced signal noise immunity ensures consistent feedback in electrically noisy settings

Space-saving compact size suits applications with limited installation room

Product model and meaning

| G | 0 | S | 38 | □ | A | 02 | 2000 | C | 3 | 2M | |||

| Category of product | Type of product | Form of main shaft | Contour of product | Size of main shaft,shaft hole | Outlet and sealing form | Outline structure | Resolution | Output form | Output signal | Cable | |||

| G:incremental type | 0:megneto- electricity | S:solid shaft | 38:φ38mm | □:φ6mm | A:side outlet rubber | 02:2outline structure2 | 10,20,50,60, 100,200,360, 400,500,600, 800,1000, 1024,1200, 2000,2048, 2500,3000, 3600,5000 | C:open collector output F:complementary output T:push pull output L:5V drive output A:24V drive output | 1:phase Asignal 2:phase AB signal 3:phase ABZ signal 4:phase ABA/B/ signal 5:phase ABZA/B/Z/ signal | Default 2m line,For non 2m, labeling is sufficient |

Wiring table

| Line color | C/F output signal | – | Line color | Loutput signal |

| brown | VCC | brown | VCC | |

| blue | GND | |||

| blue | GND | |||

| black | A phase | |||

| black | A phase | white | B phase | |

| orange | Z phase | |||

| white | B phase | |||

| black red | Aphase | |||

| orange | Z phase | white red | Bphase | |

| orange red | Z phase | |||

| shield | F ·G | |||

| shield | F ·G |

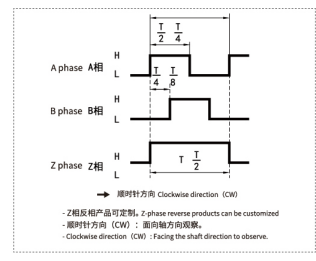

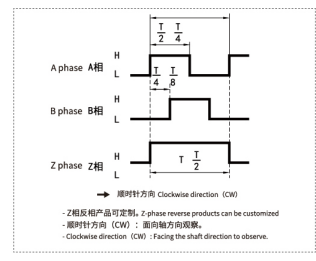

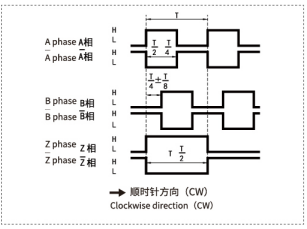

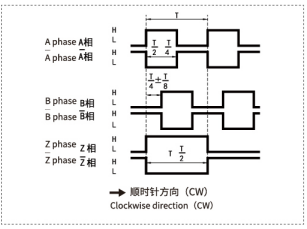

Output phase difference

complementary output/NPN collector open circuitoutput/push pull output

long line drive output

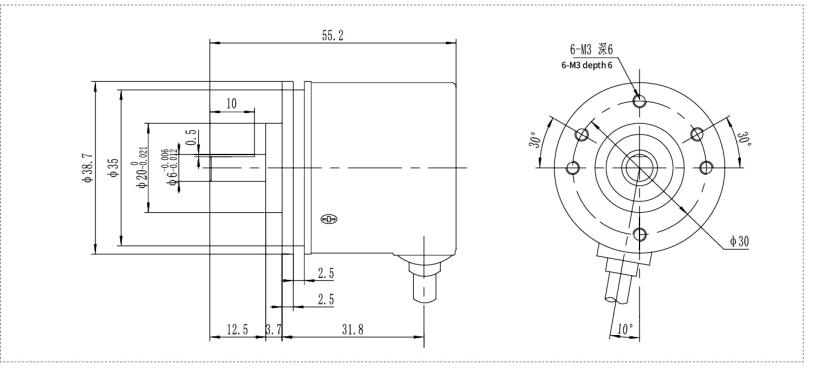

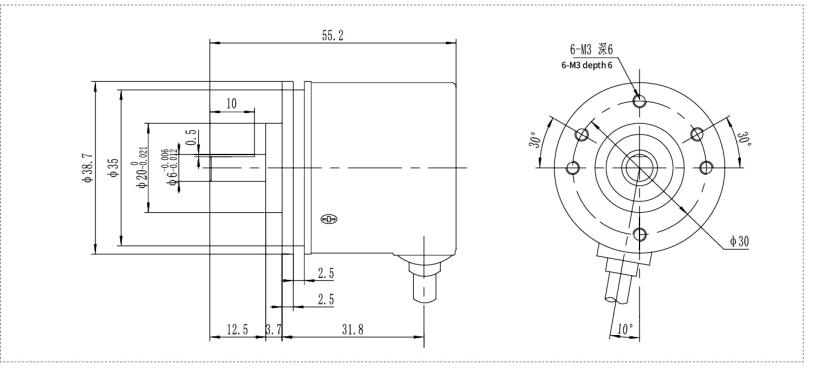

Mechanical drawings(mm)

Application Scenarios

Industrial motor speed and position measurement for automation

CNC machinery for precision tool positioning and rotation feedback

Conveyor belt speed and position control in packaging lines

Robotics requiring accurate joint and axis feedback

Printing machines for synchronizing roller and sheet movements

Automated assembly lines demanding high reliability rotary feedback

Installation & Maintenance

Verify shaft diameter and match with the semi-hollow 8mm encoder shaft for secure fitting.

Align shafts carefully to prevent mechanical stress and ensure accurate feedback. Flexible coupling is recommended.

Secure the encoder firmly with mounting screws to prevent vibrations or rotational movement.

Connect the power supply between 5 to 24V DC, and wire output signals according to required interface (refer to wiring diagrams).

Use shielded, twisted-pair cables wherever possible to minimize electromagnetic interference.

Keep the encoder housing clean and free of dust buildup.

Periodically inspect electrical connections for tightness and signs of wear.

Replace the encoder promptly if signal integrity degrades or mechanical damage occurs.

Request a Quote Now

Our team will get back to you within 24 hours.