The GOS38A03 Incremental Rotary Encoder offers reliable, high-precision feedback for industrial automation and motion control applications. With a compact 38 mm solid shaft, this encoder provides customizable resolutions up to 600 pulses per revolution (PPR), delivering accurate position, speed, and direction signals. Designed for durability, it features robust construction and versatile electrical output options, making it an ideal choice for CNC machines, packaging equipment, robotics, and other automated systems requiring precise rotational measurement.

Key Features

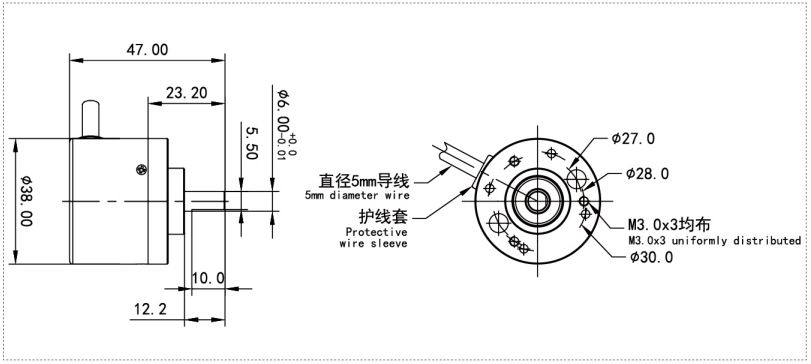

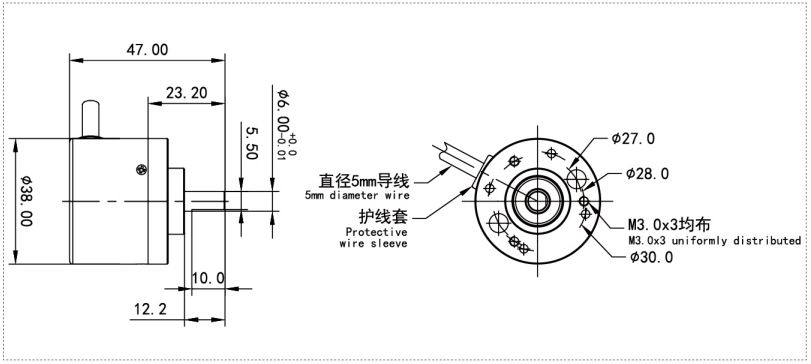

Compact 38 mm outer diameter with a 6 mm solid shaft

Custom resolution options from 100 to 600 PPR for diverse needs

Provides two-phase AB quadrature pulse outputs for direction sensing

Optional zero pulse channel for accurate indexing and homing

Multiple output signal types including open-collector, voltage, and push-pull

Robust metal housing supports high vibration and shock tolerance

Operating voltage range flexible from 5V to 24V DC

Product Advantages

Ensures stable, accurate incremental feedback for enhanced system control

Rugged mechanical design suitable for harsh industrial environments

Low power consumption and high-frequency response up to 100 kHz

Easy integration with standard industrial controllers and PLCs

Long service life due to durable bearings and sealed enclosure

Reduces maintenance requirements and system downtime

Product Model And Meaning

| G | 0 | S | 38 | □ | A | 03 | 1000 | F | 3 | 0.7M | |||

| Categoryof product | Type of product | Form of main shaft | Contour of product | Size of main shaft,shaft hole | Outlet and sealing form | Outline structure | Resolution | Output form | Output signal | Cable | |||

| G:incremental type | 0:megneto- electricity | S:solid shaft | 38:φ38mm | 口:φ6mm | A:sideoutlet rubber | 03:3 outline structure3 | 10,20,50, 60,100, 200,360 400,500, 600,800 1000,1024,1200,2000,2048,2500,3000,3600,4096 | C:open collector output F:complementary output L:5V drive output | 1:phase Asignal 2:phase AB signal 3:phase ABZ signal 4:phase ABA/B/ signal 5:phase ABZA/B/Z/ signal | Default 0.7m line,For non 0.7m, labeling is sufficient | |||

Wiring Table

| Line color | C/F output signal | – | Line color | Loutput signal |

| brown | VCC | brown | VCC | |

| blue | GND | |||

| blue | GND | |||

| black | A phase | |||

| black | A phase | white | B phase | |

| orange | Z phase | |||

| white | B phase | |||

| black red | Aphase | |||

| orange | Z phase | white red | Bphase | |

| orange red | Z phase | |||

| shield | F ·G | |||

| shield | F ·G |

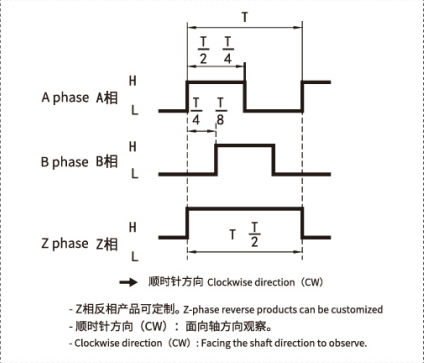

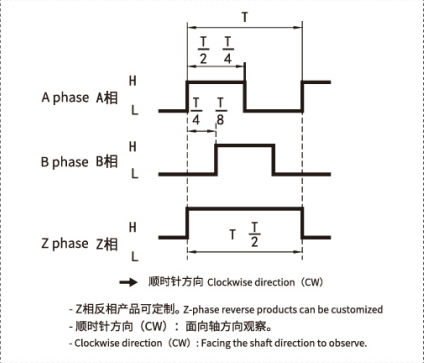

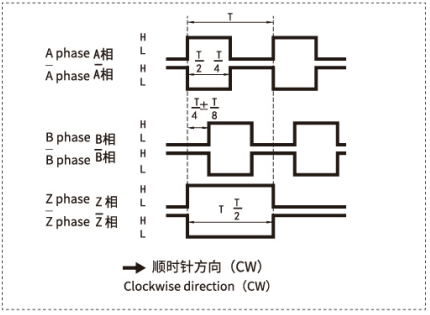

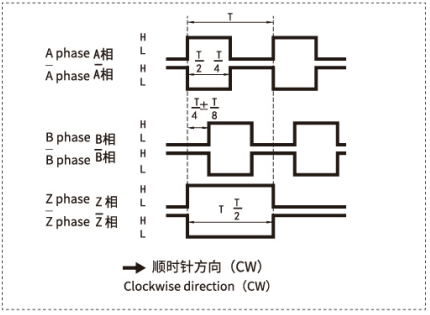

Output Phase Difference

complementary output/NPN collector open circuit output

longline drive output

Mechanical Drawings(mm)

Installation Steps & Maintenance

Align the encoder’s 6 mm shaft carefully with the machinery shaft to avoid misalignment and undue stress.

Securely mount the encoder using the designated mounting holes or flange to prevent vibration during operation.

Connect encoder output wires according to wiring diagram for ABZ phase signals, matching the control system requirements.

Confirm power supply is within specified voltage range (5-24V DC).

Perform testing by rotating the shaft to verify pulse output and direction detection.

For routine maintenance, periodically inspect the encoder for dirt, dust, and secure wiring connections. Clean gently without solvents if necessary.

Due to sealed bearings, lubrication is generally unnecessary, minimizing upkeep.

Applications

Precision feedback for CNC machinery and tool positioning

Automated packaging and printing equipment speed control

Robotics for accurate motion and position sensing

Conveyor systems requiring precise speed and direction feedback

Industrial automation processes needing reliable rotary measurements

Medical equipment where exact rotational control is crucial

Request a Quote Now

Our team will get back to you within 24 hours.