Desvendando a magia dos sensores capacitivos: Como eles funcionam e por que são importantes

Neste artigo, vamos nos aprofundar no mundo dos sensores capacitivos e explorar seus princípios e aplicações.

Leia mais

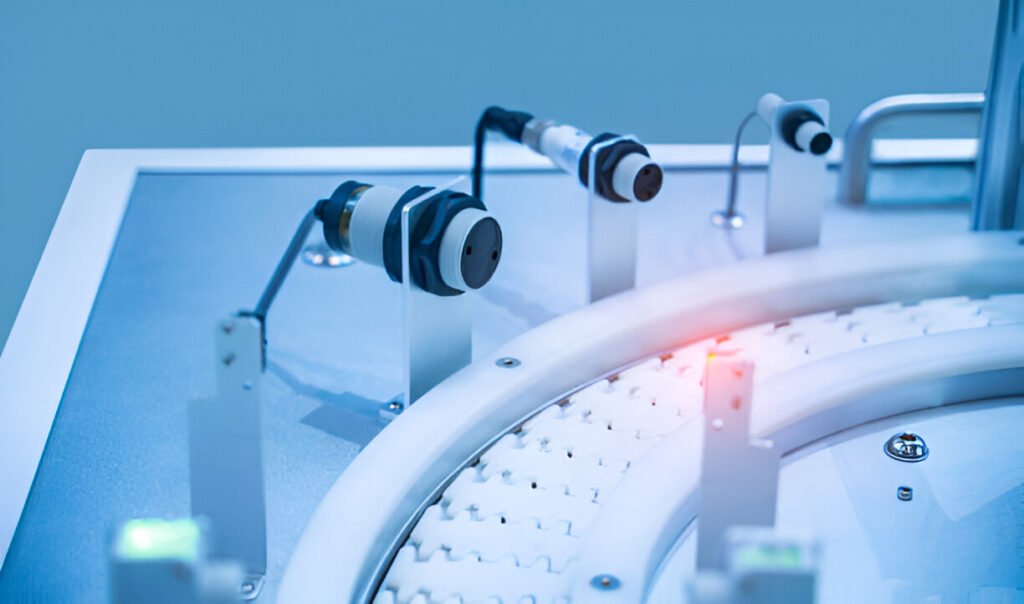

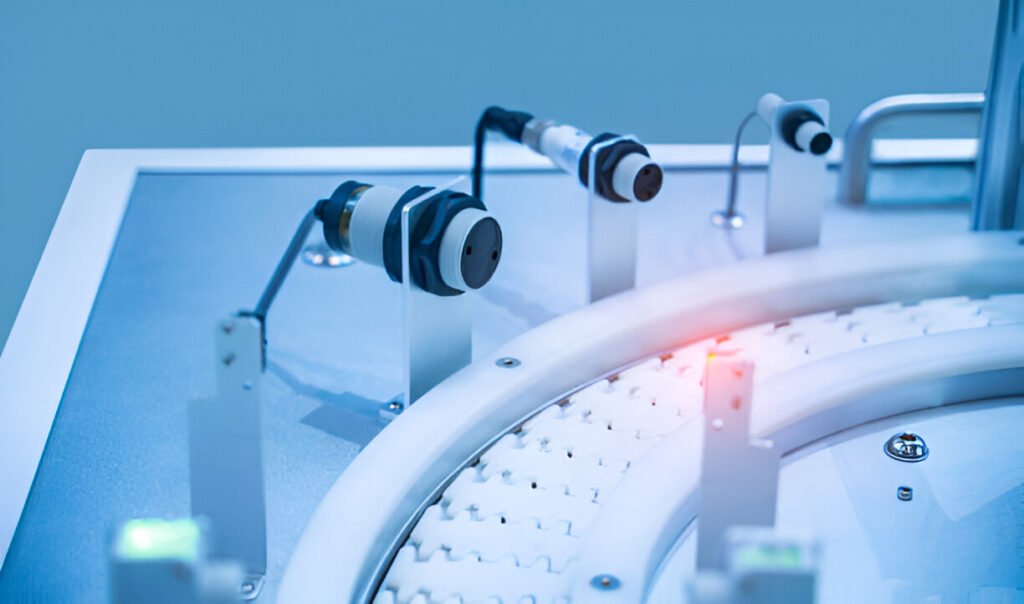

Have you ever wondered how machines in factories “see” objects without actually touching them? That’s the magic of sensor do interruptor de proximidade. A proximity switch sensor is an electronic device designed to detect the presence of nearby objects without physical contact.

Imagine a production line where proximity sensors accurately detect products on a conveyor belt and control machinery accordingly, without any mechanical contact or wear. This greatly increases efficiency and safety. That’s why proximity switch sensors play an irreplaceable role in manufacturing, automation, and safety systems.

Today, we’ll dive deep into the working principle, types, applications, and common issues of proximity switch sensors to help you better understand and choose the right products for your factory. If you’re considering upgrading your production line’s intelligence, this article is the perfect start!

The core appeal of proximity switch sensor lies in their “contactless detection” ability. This means they detect objects entering a preset detection range and trigger corresponding electrical signals without physical touch.

The working process is simple yet precise:

| Advantage | Descrição |

|---|---|

| Contactless Detection | Avoids mechanical wear, extends life |

| Fast Response | Millisecond detection for fast lines |

| Fácil instalação | No complex mechanical parts |

| Wide Applicability | Suitable for many materials & conditions |

| High Stability | Excellent resistance to interference |

This mechanism allows devices to keep perfect timing without relying on mechanical switches prone to wear and tear. Imagine reduced maintenance and downtime—wouldn’t that streamline your factory operation?

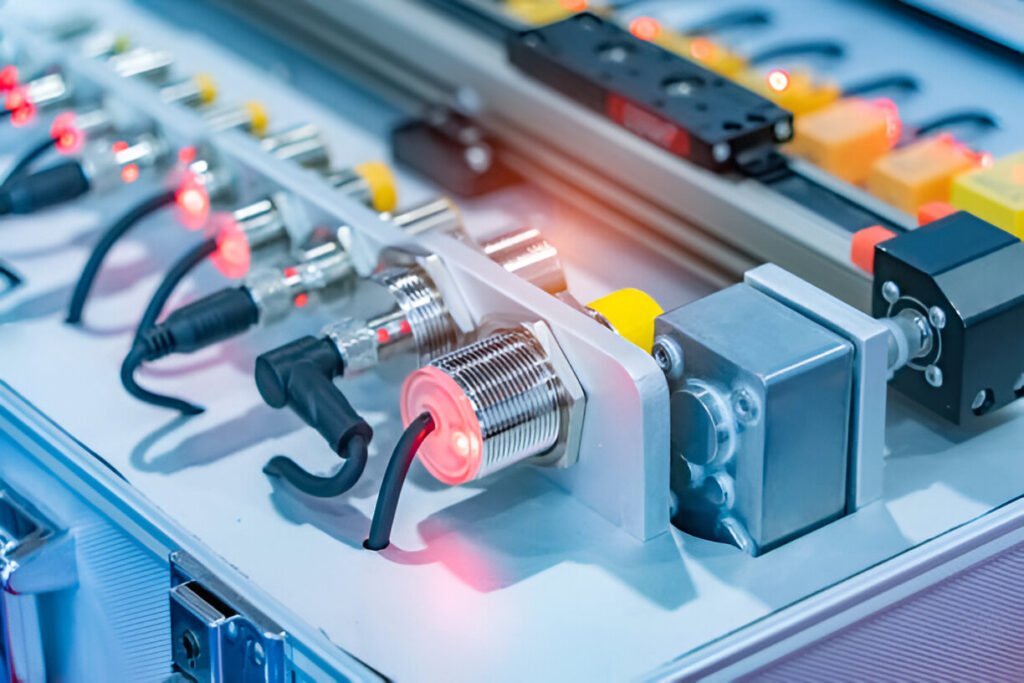

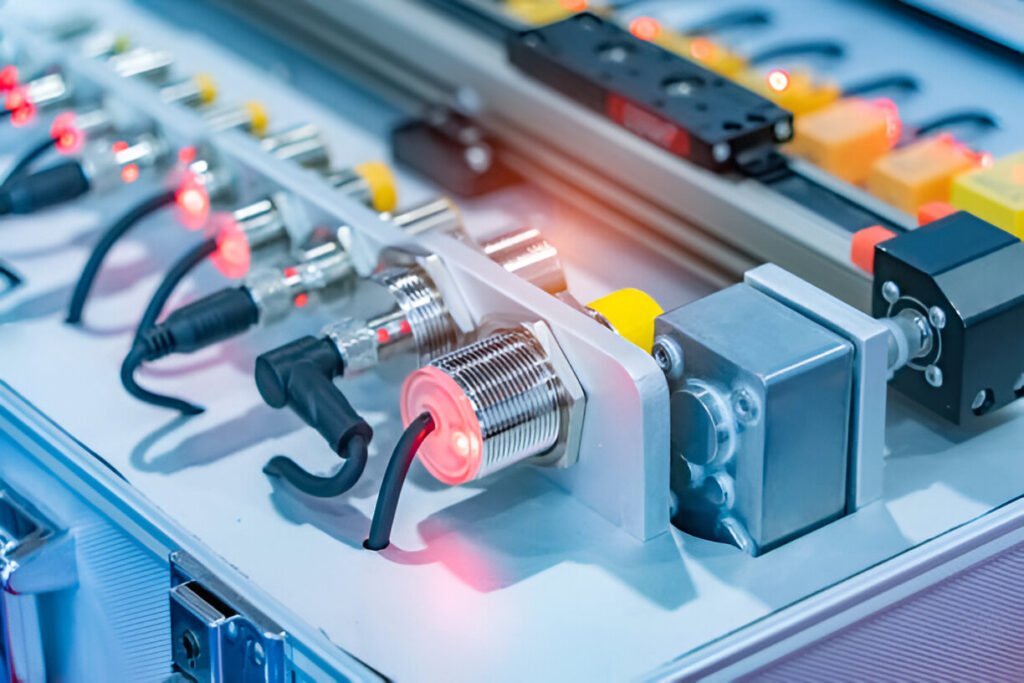

Choosing the right type is crucial to meet detection needs and environmental conditions.

| Tipo | Princípio de funcionamento | Suitable For | Pros and Cons |

|---|---|---|---|

| Indutivo | Detects metal objects through electromagnetic induction | Metals (iron, steel, other conductive metals) | High precision and stability; metal-only detection |

| Capacitivo | Detects changes in capacitance | Metals, plastics, liquids, wood | Wide application; sensitive to environment |

| Magnético | Uses magnetic field or reed switch | Magnetic or magnet-assisted objects | Simple structure; waterproof; moderate range |

| Fotoelétrico | Emits and receives light to detect presence | Various materials; long-distance | Long range and high sensitivity; sensitive to dust |

For instance, if you mainly detect metal parts, an inductive sensor is ideal; for plastics or liquid levels, capacitive sensors work best.

Upgrade your automation with smart proximity switch sensor. Reach out to our experts for the perfect solution tailored to your needs.

To truly grasp these sensors, let’s explore their sensing and signal processes.

Inductive sensors have a high-frequency oscillator that creates an electromagnetic field. When metal objects disturb this field, the oscillation amplitude drops, triggering the switch.

Capacitive sensors detect changes in the electric field’s capacitance when the object is close. This works for both metallic and non-metallic objects.

Processed signals are amplified and filtered internally, then converted into switch outputs for use in control systems. The entire process is rapid and accurate.

| Tipo de sensor | Working Mechanism | Detection Method |

|---|---|---|

| Indutivo | Metal disturbs electromagnetic oscillation | Electromagnetic induction |

| Capacitivo | Object changes electric field capacitance | Capacitance sensing |

| Magnético | Magnetic field actuation or reed switch | Magnetic detection |

| Fotoelétrico | Light beam interrupted or reflected | Optical detection |

Though complex, these principles form the foundation of industrial automation technology. Understanding them helps you confidently select suitable sensors.

Choosing correctly ensures accurate sensing and long-lasting, stable operation. Key considerations:

| Fator | Descrição | Focus Point |

|---|---|---|

| Target Material | Metal or non-metal | Determines sensor type |

| Sensing Distance | Max detection range needed | Meet production requirements |

| Meio ambiente | Temperature, humidity, dust, interference | Select protective models |

| Sinal de saída | NPN, PNP, normally open/closed | Compatible with control system |

| Installation Space | Size and mounting style | Plan equipment layout |

A quick selection roadmap:

| Step | Process |

|---|---|

| 1 | Identify target material |

| 2 | Confirm sensing distance & accuracy |

| 3 | Evaluate environment & interference |

| 4 | Choose output type & power supply |

| 5 | Pick sensor size & installation method |

Correct sensor choice boosts sensitivity, reduces false triggers, and lowers downtime. Any doubts? Contact us for tailored advice from our experts.

The demand for proximity switch sensors grows steadily as global manufacturing becomes smarter and more digital. They are essential in factory automation, robotics, smart logistics, and smart warehousing.

Digital communication technologies like IO-Link and adjustable sensors make sensors more flexible and intelligent. You can remotely adjust sensitivity and monitor sensor health for predictive maintenance.

| Trend | Descrição |

|---|---|

| Intelligence | Adjustable parameters, remote monitoring |

| Connectivity | IoT integration, data networking |

| Multi-functionality | Combining temperature, pressure, and more sensors |

| Reliability | Adapt to difficult environments, longer life |

| Customization | Industry and environment-specific designs |

As a supplier, we keep pace with leading tech to bring you the most advanced and reliable sensors and service.

Proximity switch sensors are the “eyes” of industrial automation, becoming smarter, more accurate, and reliable. With advancing technology, they evolve into intelligent devices integrated into smart manufacturing systems.

Future sensores de proximidade will offer advanced detection and feedback capabilities empowered by IoT and AI. This means boosted equipment efficiency and easier maintenance for more flexible factory operation.

Ready to upgrade your system or find the right proximity switch sensor for a new project? Contact us today. We offer quality products and professional support to help your automation journey succeed.

The max stable detection distance with a standard test object. Real distance varies by material and size.

They rely on eddy currents generated in conductive metals, which non-metals cannot produce.

Yes, they sense changes in dielectric constant, enabling detection of plastics, liquids, and more.

Possible reasons: unstable mounting, target out of specs, temperature changes, unstable power supply.

Match sensor type, detection range, environment, and control system compatibility.

Check wiring, system compatibility, or sensor damage.

Yes, but ensure electrical design avoids signal interference.

Operating distance is where the sensor activates, release distance is where it deactivates, allowing hysteresis to prevent false activation.

Leave safety distance margin, avoid interference, and perform regular maintenance.

Greatly. Use power supply within specs to ensure stable operation.