The GOS5008B Rotary Encoder is engineered to deliver robust and reliable rotational feedback, ensuring consistent performance in demanding environments. Featuring a rugged design and versatile output options, this encoder offers accurate speed and position signals that are essential for various automation and machinery applications. Designed for heavy-duty use, it supports enhanced motion monitoring and control with minimal maintenance requirements.

Principais recursos:

High-resolution incremental output providing stable and consistent pulse signals

Rugged, dustproof, and vibration-resistant housing for long-lasting durability

Supports multiple output formats including TTL and open collector signals

Standard flange mounting and shaft coupling for easy and secure installation

Sealed enclosure and premium bearings to extend operational lifespan

Wide voltage range for seamless integration with different power supplies

Vantagens do produto:

Delivers dependable and steady feedback to optimize machine motion accuracy

Heavy-duty construction minimizes downtime from wear and harsh conditions

Flexible output and mounting options simplify system integration

Enhances machine performance by ensuring real-time and precise motion data

Compact size fits easily into confined spaces without compromising performance

Modelo e significado do produto

| G | 0 | s | 50 | 06 | B | 1000 | c | 3 | 2M | |||

| Categoria de produto | Type of product | Form of main shaft | Contorno de produto | Tamanho do eixo principal, furo do eixo

| Saída e formulário de selagem | Resolução | Formulário de saída | Sinal de saída | Cabo | |||

| G:tipo incremental | 0:megneto electricity L:photoelec- tricidade | S: eixo sólido | 50:φ50mm | □:φ8mm 06:φ6mm | E:side outlet metal D:rear-outlet metal | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C: saída de coletor aberto F: saída complementar T:saída push pull L:Saída de acionamento de 5V A:Saída de acionamento de 24V | 1: phase Asignal 2: phase AB signal 3:fase do sinal ABZ 4:fase Sinal ABA/B/ 5:fase do sinal ABZA/B/Z/ | Padrão 2m lne,For não 2m, labeing is suficiente |

Tabela de fiação

| Cor da linha | Sinal de saída C/F/T | Cor da linha | Sinal de saída L/A | |

| vermelho | VCC | vermelho | VCC | |

| preto | GND | |||

| preto | GND | |||

| verde | Uma fase | |||

| verde | Uma fase | branco | Fase B | |

| amarelo | Fase Z | |||

| branco | Fase B | |||

| marrom | Uma fase | |||

| amarelo | Fase Z | cinza | Fase B | |

| laranja | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

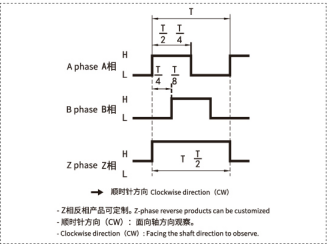

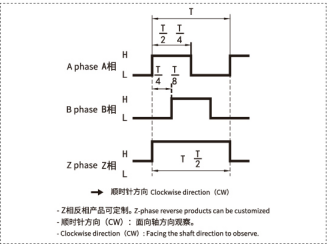

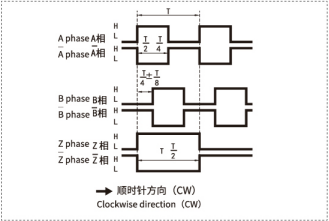

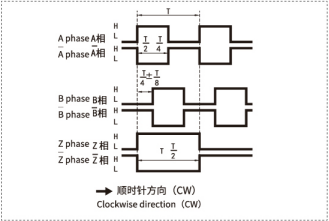

Diferença de fase de saída

saída complementar/push pull Saída de circuito aberto de coletor NPN/saída de circuito aberto

saída de acionamento de palangre

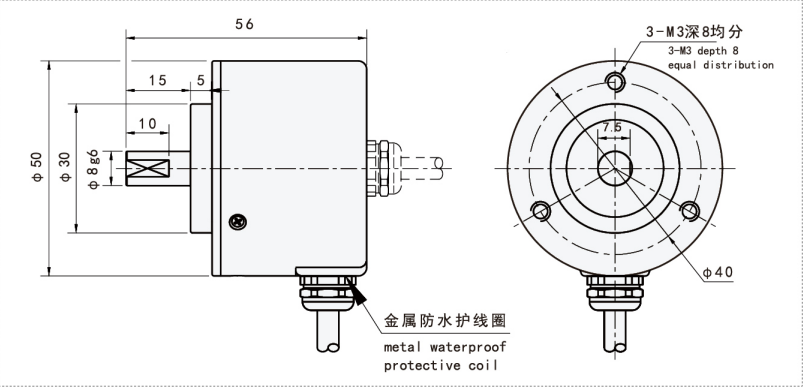

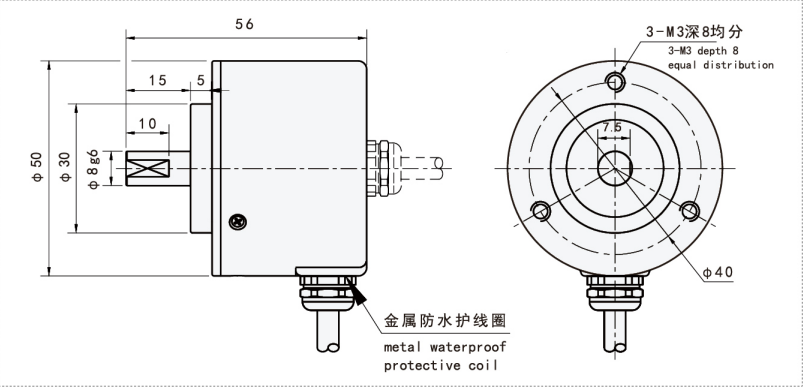

Desenhos mecânicos (mm)

Installation and Maintenance:

Mount the GOS5008B encoder securely to the equipment shaft using the supplied coupling or adapter.

Ensure precise shaft alignment to avoid mechanical wear and signal distortion.

Connect the wiring according to the provided schematic, verifying all connections for correctness.

Test output signals with your control or monitoring system before full operation.

Periodically clean the encoder housing to eliminate dust and debris accumulation.

Inspect mounting hardware, mechanical couplings, and electrical connectors regularly; lubricate components as recommended.

Detailed Product Applications:

Ideal for rugged and sensitive environments, the GOS5008B Rotary Encoder is perfect for:

Material handling and conveyor systems requiring precise speed and position monitoring

Robotic arms and automated machinery demanding consistent motion feedback

Packaging and printing equipment for accurate synchronization and quality control

Elevator and escalator systems to ensure smooth, safe shaft rotations

Renewable energy systems such as wind turbines for blade positioning and speed sensing

Agricultural and construction machinery functioning in harsh outdoor conditions

Medical devices and laboratory instruments requiring reliable rotational data

The GOS5008B is part of a broader category of incremental rotary encoders that have significantly advanced in technology, focusing on enhancing durability and signal integrity in challenging environments. These encoders play a crucial role in enabling smart automation by supplying real-time rotational data that directly impacts system precision and efficiency. Understanding proper installation practices and maintenance routines is key to maximizing encoder performance and longevity. Moreover, innovations in encoder materials and sealing technologies continue to push the limits of their application, opening doors for their use in extreme conditions such as offshore energy production and heavy machinery in mining operations.

Solicite uma cotação agora

Nossa equipe entrará em contato com você em 24 horas.