O codificador rotativo incremental GOS38A03 oferece feedback confiável e de alta precisão para aplicações de automação industrial e controle de movimento. Com um eixo sólido compacto de 38 mm, esse codificador oferece resoluções personalizáveis de até 600 pulsos por revolução (PPR), fornecendo sinais precisos de posição, velocidade e direção. Projetado para durar, ele apresenta construção robusta e opções versáteis de saída elétrica, o que o torna a escolha ideal para máquinas CNC, equipamentos de embalagem, robótica e outros sistemas automatizados que exigem medição rotacional precisa.

Principais recursos

Diâmetro externo compacto de 38 mm com um eixo sólido de 6 mm

Opções de resolução personalizadas de 100 a 600 PPR para diversas necessidades

Fornece saídas de pulso de quadratura AB de duas fases para detecção de direção

Canal de pulso zero opcional para indexação e localização precisas

Vários tipos de sinal de saída, incluindo coletor aberto, tensão e push-pull

O invólucro metálico robusto suporta alta tolerância a vibrações e choques

Faixa de tensão operacional flexível de 5V a 24V CC

Vantagens do produto

Garante um feedback incremental estável e preciso para um controle aprimorado do sistema

Design mecânico robusto adequado para ambientes industriais adversos

Baixo consumo de energia e resposta de alta frequência de até 100 kHz

Fácil integração com controladores industriais padrão e PLCs

Longa vida útil devido aos rolamentos duráveis e ao gabinete vedado

Reduz os requisitos de manutenção e o tempo de inatividade do sistema

Modelo e significado do produto

| G | 0 | S | 38 | □ | A | 03 | 1000 | F | 3 | 0.7M | |||

| Categoria do produto | Tipo de produto | Forma de eixo principal | Contorno de produto | Tamanho do eixo principal, furo do eixo | Saída e formulário de selagem | Esboço estrutura | Resolução | Formulário de saída | Sinal de saída | Cabo | |||

| G:incremental tipo | 0:megneto- eletricidade | S: eixo sólido | 38:φ38mm | 口:φ6mm | A:borracha da saída lateral | 03:3 esboço estrutura3 | 10,20,50, 60,100, 200,360 400,500, 600,800 1000,1024,1200,2000,2048,2500,3000,3600,4096 | C: saída de coletor aberto F: saída complementar L:Saída de acionamento de 5V | 1:fase Asignal 2:sinal de fase AB 3:fase do sinal ABZ 4:fase Sinal ABA/B/ 5:fase do sinal ABZA/B/Z/ | Padrão 0.7m linha, para não 0,7 m, A rotulagem é suficiente | |||

Tabela de fiação

| Cor da linha | Sinal de saída C/F | – | Cor da linha | Sinal de saída |

| marrom | VCC | marrom | VCC | |

| azul | GND | |||

| azul | GND | |||

| preto | Uma fase | |||

| preto | Uma fase | branco | Fase B | |

| laranja | Fase Z | |||

| branco | Fase B | |||

| preto vermelho | Fase | |||

| laranja | Fase Z | branco vermelho | Fase B | |

| vermelho alaranjado | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

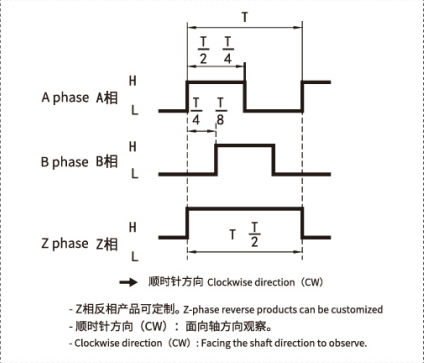

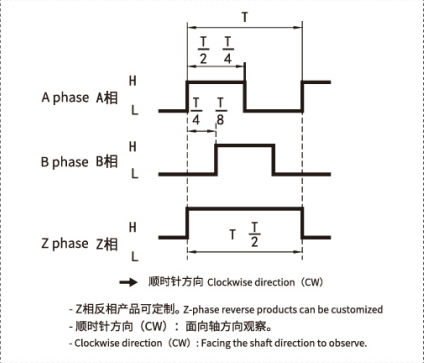

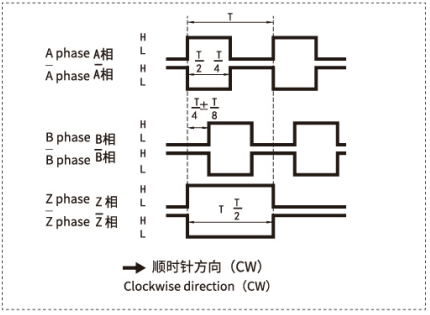

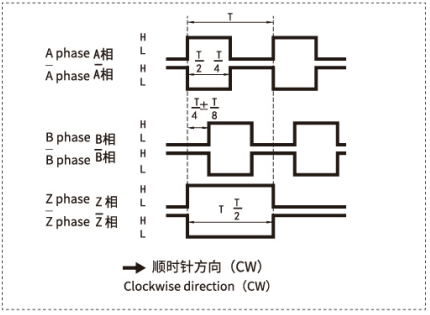

Diferença de fase de saída

saída complementar/saída de circuito aberto de coletor NPN

saída de acionamento de palangre

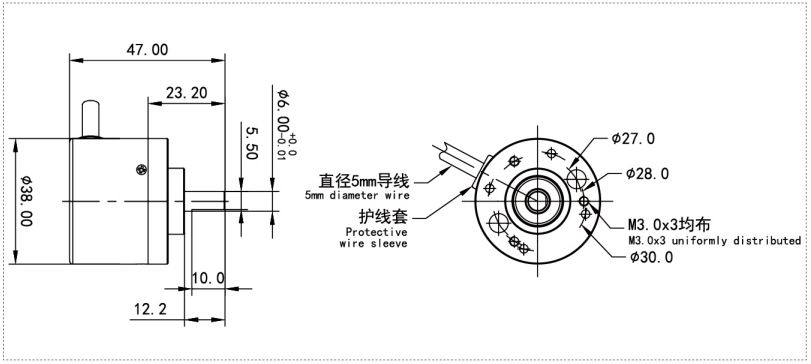

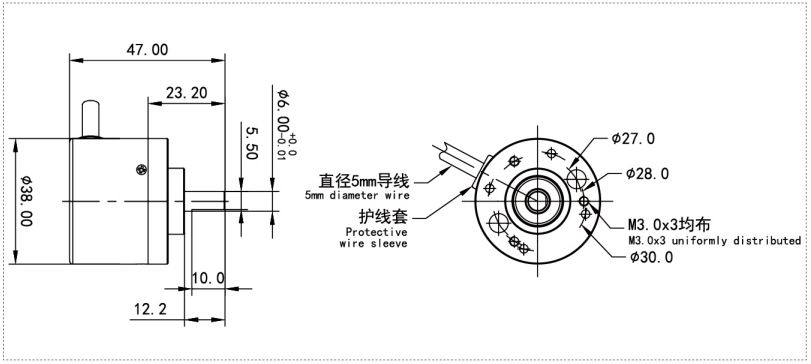

Desenhos mecânicos (mm)

Etapas de instalação e manutenção

Alinhe cuidadosamente o eixo de 6 mm do codificador com o eixo do maquinário para evitar desalinhamento e estresse indevido.

Monte o codificador com segurança usando os orifícios de montagem designados ou o flange para evitar vibrações durante a operação.

Conecte os fios de saída do codificador de acordo com o diagrama de fiação para os sinais de fase ABZ, de acordo com os requisitos do sistema de controle.

Confirme se a fonte de alimentação está dentro da faixa de tensão especificada (5-24V CC).

Realize o teste girando o eixo para verificar a saída de pulso e a detecção de direção.

Para manutenção de rotina, inspecione periodicamente o codificador quanto a sujeira, poeira e conexões de fiação seguras. Limpe suavemente sem solventes, se necessário.

Devido aos rolamentos vedados, a lubrificação geralmente não é necessária, minimizando a manutenção.

Aplicativos

Feedback de precisão para máquinas CNC e posicionamento de ferramentas

Controle de velocidade de equipamentos automatizados de embalagem e impressão

Robótica para detecção precisa de movimento e posição

Sistemas de transporte que exigem feedback preciso de velocidade e direção

Processos de automação industrial que necessitam de medições rotativas confiáveis

Equipamentos médicos em que o controle rotacional exato é crucial

Solicite uma cotação agora

Nossa equipe entrará em contato com você em 24 horas.