The GOS5008A01 Incremental Rotary Encoder provides dependable rotational feedback with a rugged design suitable for various machinery and automation systems. Offering multiple output formats and high durability, this encoder ensures consistent speed and position data for efficient motion tracking. Its robust construction and ease of integration make it highly adaptable to challenging operational environments.

Principais recursos:

High-resolution incremental output delivering stable pulse signals

Rugged, sealed design protecting against dust, moisture, and vibrations

Supports TTL and open collector output formats for versatile system integration

Standard flange mounting and shaft coupling for straightforward installation

Premium bearings and a sealed enclosure to extend service life

Wide voltage input range compatible with various power supplies

Vantagens do produto:

Provides reliable and steady feedback to enhance motion monitoring accuracy

Durable construction minimizes downtime in harsh operational conditions

Flexible mounting and output options facilitate easy adaptability

Improves machine efficiency by supplying real-time rotational data

Compact design supports use in space-constrained equipment setups

Modelo e significado do produto

| G | 0 | s | 50 | 08 | A | 01 | 1000 | C | 3 | 2M | |||

| Categoria de produto | Tipo de produto | Forma de eixo principal | Contorno de produto | Tamanho do eixo principal, furo do eixo | Saída e formulário de selagem | Outline structure | Resolução | Formulário de saída | Sinal de saída | Cabo | |||

| G:incremental tipo | O:megneto- electricity | S: eixo sólido | 50:φ50mm | 08:φ8mm | A: saída lateral de borracha | 01:1 outline structure 1 | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024, 1200,2000 2048,2500, 3000,3600, 4096 | F: saída complementar L:Saída de acionamento de 5V A:Saída de acionamento de 24V | 1:fase Asignal 2:sinal de fase AB 3:fase do sinal ABZ 4:fase Sinal ABA/B/ 6:phase ABZA/B/Z/ signal | Padrão 2m linha,Para não 2m, a rotulagem é suficiente | |||

Tabela de fiação

| Cor da linha | Sinal de saída C/F/T | Cor da linha | Sinal de saída L/A | |

| marrom | VCC | marrom | VCC | |

| azul | GND | |||

| azul | GND | |||

| preto | Uma fase | |||

| preto | Uma fase | branco | Fase B | |

| laranja | Fase Z | |||

| branco | Fase B | |||

| preto vermelho | Uma fase | |||

| laranja | Fase Z | branco vermelho | Fase B | |

| vermelho alaranjado | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

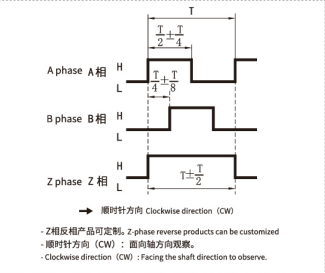

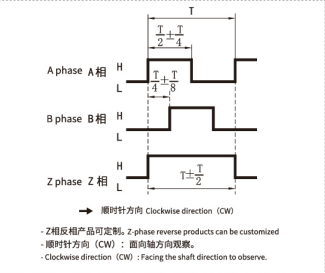

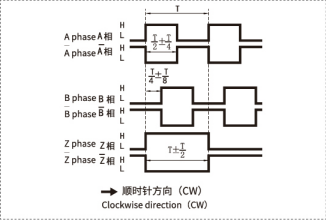

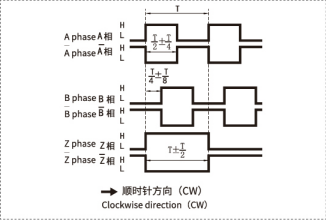

Diferença de fase de saída

complementary output

saída de acionamento de palangre

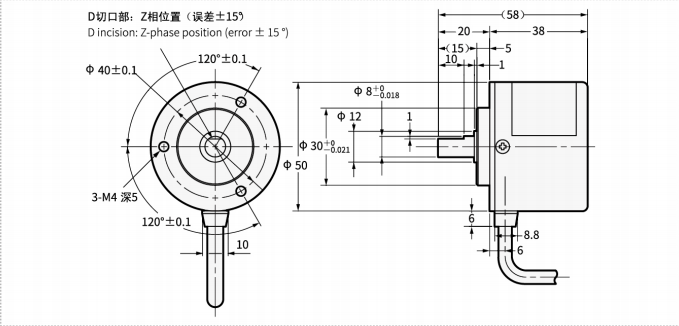

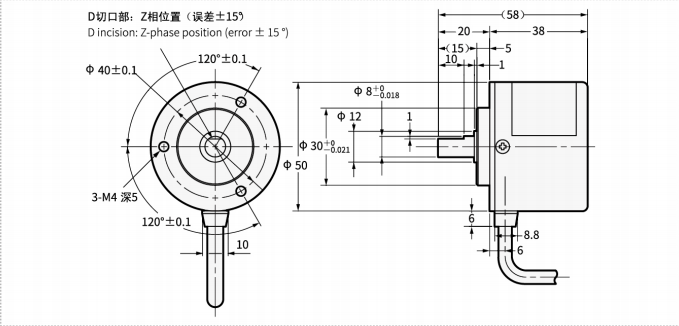

Desenhos mecânicos (mm)

Installation and Maintenance:

Securely mount the GOS5008A01 encoder onto the equipment shaft using the provided coupling or adapter.

Align the encoder shaft carefully to avoid mechanical stress and signal inaccuracies.

Connect wiring based on the provided schematic, ensuring correct power and signal connections.

Test output signals with your control or monitoring system before full operation.

Clean the encoder housing regularly to prevent dust and contaminant buildup.

Periodically inspect mounting hardware and electrical connections; lubricate as recommended.

Detailed Product Applications:

Suitable for a wide array of equipment and environments, including:

Conveyor and material handling systems requiring precise speed and position feedback

Robotics and automated equipment needing consistent motion data

Printing and packaging machinery for synchronization and quality control

Elevator and escalator systems for reliable shaft rotation monitoring

Renewable energy applications including wind turbines for blade position tracking

Agricultural and heavy machinery exposed to challenging environmental conditions

Medical devices and laboratory instruments requiring dependable motion feedback

Rotary encoders like the GOS5008A01 are pivotal in advancing automated systems by improving motion accuracy and reliability. Ongoing innovations in encoder sealing technology and signal processing continue to enhance performance in harsh environments and challenging applications. Proper installation, including shaft alignment and wiring integrity, plays a crucial role in maximizing encoder lifetime and output quality. Furthermore, integrating encoders with modern digital control systems enables predictive maintenance and performance analytics, contributing to smarter, more efficient machinery operations.

Solicite uma cotação agora

Nossa equipe entrará em contato com você em 24 horas.