The GOS38A04 Incremental Rotary Encoder is designed for precise motion and position feedback in demanding industrial automation environments. Featuring a robust 38 mm shaft and customizable resolution up to 600 pulses per revolution (PPR), this encoder delivers reliable and accurate AB quadrature signals ideal for speed, position, and direction sensing applications. Engineered for durability, the encoder supports versatile installation with rugged construction and stable output signals, ensuring long-lasting performance in diverse automation and motion control systems.

Principais recursos

Solid 38 mm shaft diameter for heavy-duty usage

Customizable resolution up to 600 PPR for precise measurement

Standard AB quadrature output signals with high noise immunity

Robust construction suitable for industrial environments

Supports both clockwise and counterclockwise rotation detection

Optional zero pulse (Z channel) for reference marking and homing

Vantagens do produto

High accuracy and repeatability increase system reliability

Durable mechanical design with resistance to vibration and shock

Flexible output options allow easy integration with PLCs, controllers, and industrial drives

Long operational lifespan with stable performance in harsh conditions

Low starting torque reduces wear and extends gearbox and motor life

Cost-effective solution with maintenance-friendly design

Modelo e significado do produto

| G | 0 | S | 38 | □ | A | 04 | 1000 T | 3 | 2M | ||||

| Category of produto | Tipo de produto | Forma de eixo principal | Contorno de produto | Tamanho do principal eixo, furo do eixo | Saída e formulário de selagem | Outline structure | Resolução | Formulário de saída | Sinal de saída | Cabo | |||

| G:incremental tipo | 0:megneto- eletricidade | S: eixo sólido | 38:φ38mm | □:φ6mm | A: saída lateral de borracha | 04:4 outline structure4 | 10,20,50, 60,100, 200,360, 400,500 600,800, 1000,1024,1200, 2000,2048,2500,3000,3600, 4096 | T:saída push pull L:Saída de acionamento de 5V A:Saída de acionamento de 24V | 1Aphase Asignal 2:ABphase AB signal 3:ABZphase ABZ signal 4:fase Sinal ABA/B/ 5:fase do sinal ABZA/B/Z/ | Padrão 2m line,For non 2m, labeling is sufficient | |||

Tabela de fiação

| Cor da linha | T output signal | – | Cor da linha | Sinal de saída L/A |

| marrom | VCC | marrom | VCC | |

| azul | GND | |||

| azul | GND | |||

| preto | Uma fase | |||

| preto | Uma fase | branco | Fase B | |

| laranja | Fase Z | |||

| branco | Fase B | |||

| preto vermelho | Fase | |||

| laranja | Fase Z | branco vermelho | Fase B | |

| vermelho alaranjado | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

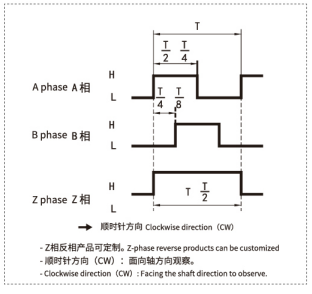

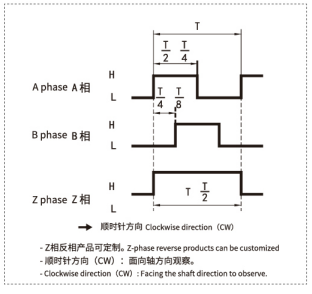

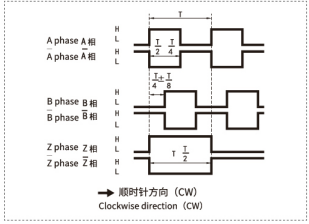

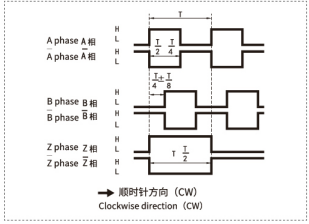

Diferença de fase de saída

push pull output

saída de acionamento de palangre

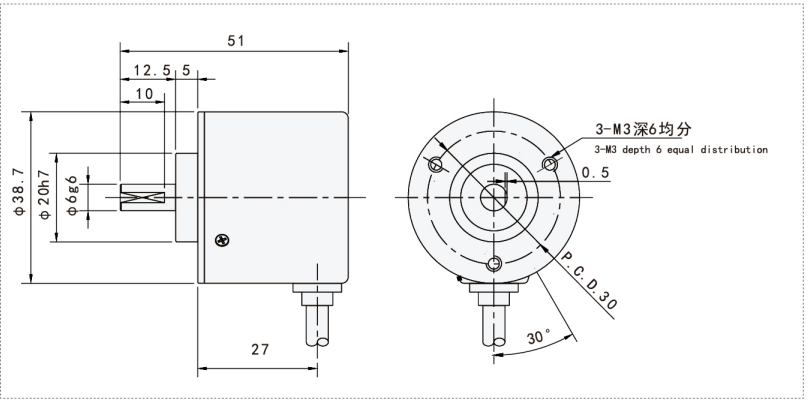

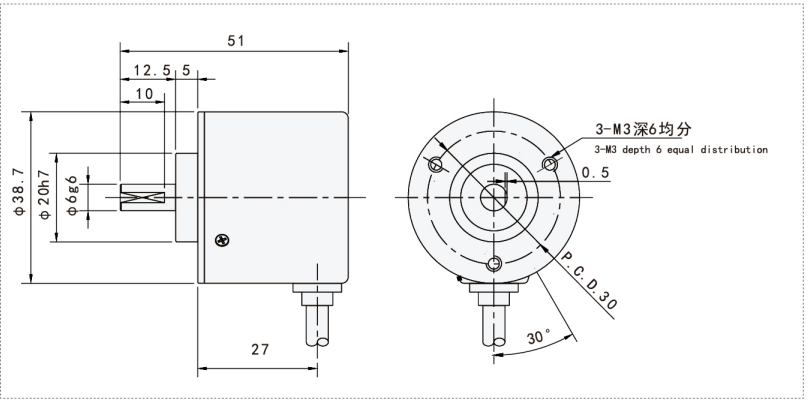

Desenhos mecânicos (mm)

Etapas de instalação e manutenção

Secure the encoder shaft firmly to the rotating equipment shaft, ensuring proper alignment to avoid mechanical stress.

Connect the encoder output cables to your control system inputs, verifying wiring according to ABZ signal specifications.

Set the desired resolution and pulse count if customization is available; otherwise, use default factory settings.

Perform initial rotation tests to confirm signal output and direction detection accuracy.

Periodically inspect the encoder and connections for dirt, debris, or wear and clean gently to maintain optimal function.

Lubricate bearings if specified in the user manual (most models are sealed and maintenance-free).

Aplicativos

Industrial automation and robotics requiring precise angular position feedback

CNC machinery for tool positioning and speed control

Conveyor systems and packaging machines for accurate motion monitoring

Printing machinery for synchronized speed and position sensing

Medical device instrumentation requiring high-precision rotary feedback

Elevators and escalators for motor position verification

Solicite uma cotação agora

Nossa equipe entrará em contato com você em 24 horas.