History and Evolution of Aviation Connector Plugs

Aviation connector plugs have a rich history that dates back to the 1930s and 1950s, when rapid advancements in military and aerospace technology called for reliable electrical connections. Initially, these connectors were developed as part of mil-spec (military specification) standards to ensure durability and performance under extreme conditions such as high vibration, temperature shifts, and exposure to dust and moisture.

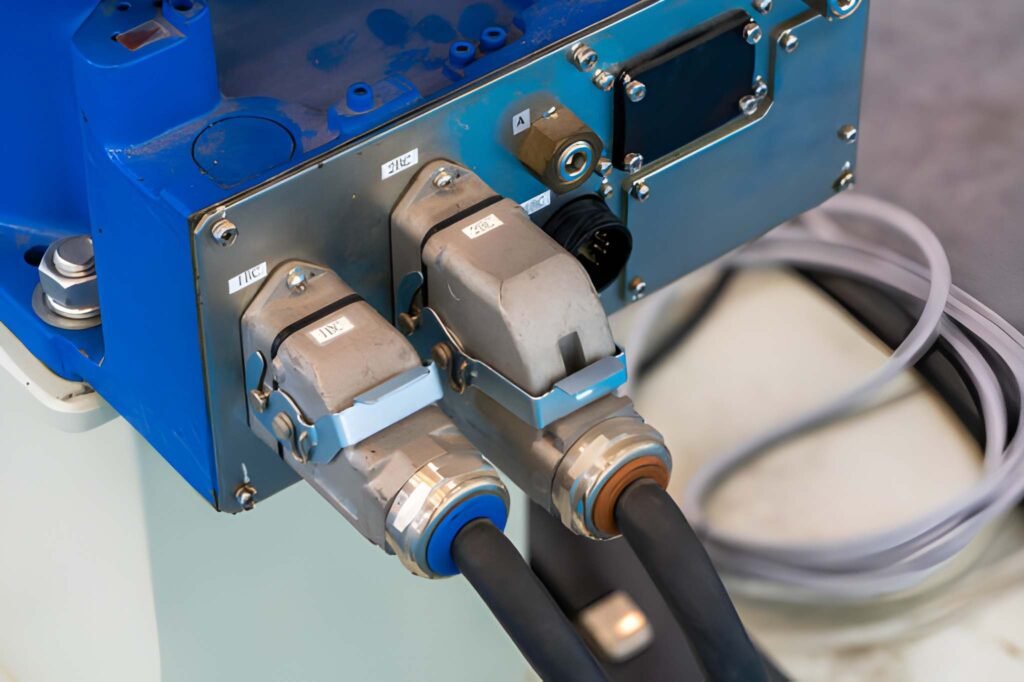

During this era, rugged circular electrical connectors with threaded locking mechanisms became popular, providing secure and stable connections vital for avionics systems. Over time, as aviation technology expanded beyond strict military use, the demand grew for more affordable, versatile alternatives without sacrificing reliability.

This led to the transition from original mil-spec connectors to the widely recognized GX series aviation connector plugs. The GX series, including models like GX12, GX16, and GX20, developed into standardized circular aviation plugs that balanced ruggedness with ease of use. These connectors became staples not only in aviation but also in industrial, marine, and outdoor electronics applications due to their waterproof ratings and sturdy metal or plastic construction.

Today’s aviation connector plugs blend the legacy of military-grade performance with modern design improvements, catering to a broad market that includes both professional and DIY users. Whether it’s the classic metal aviation socket or a waterproof GX16 aviation connector, these components continue to be essential for dependable electrical connections in demanding environments.

Key Features and Benefits of Aviation Connector Plugs

Aviation connector plugs stand out thanks to their robust design and reliability. Here’s what makes them a go-to choice across industries:

Threaded Locking Mechanism

- Ensures a secure connection that won’t loosen from vibration or movement.

- Provides quick and firm mating, preventing accidental disconnections during operation.

Material Construction

- Available in metal (often aluminum or zinc alloy) for ruggedness and durability.

- Plastic versions offer lightweight alternatives with good insulating properties, ideal for less harsh environments.

- Both types resist impact and wear better than standard connectors.

Waterproof and Dustproof Ratings

- Commonly rated IP65 to IP68, meaning they resist water jets, dust ingress, and even short-term immersion.

- These ratings make them perfect for outdoor, marine, and industrial use where exposure to elements is expected.

Temperature and Vibration Resistance

- Designed to handle broad temperature ranges (-40°C to +105°C or more).

- Vibration-proof features reduce wear on contacts, extending durability in tough settings like aviation or heavy machinery.

Advantages Over Standard Plugs

| Характеристика | Aviation Connector Plug | Standard Plug |

|---|

| Locking Mechanism | Threaded lock for secure connections | Push-fit or snap-in, less secure |

| Environmental Ratings | Waterproof & dustproof (up to IP68) | Usually no waterproof rating |

| Долговечность | Metal/plastic with vibration & heat resistance | Often plastic, less durable |

| Приложения | Heavy-duty, industrial, avionics, outdoor | Mainly indoor, light-duty |

These key features make aviation connectors ideal for professionals needing dependable, rugged circular plugs that outlast typical connectors. If you want to pair them with suitable accessories, check out our range of silicon rubber cable glands designed for tight sealing and durability.

Common Types of Aviation Connector Plugs

Aviation connector plugs come in several popular types, especially within the GX series, known for their reliability and versatility. The most common sizes include:

- GX12: Compact and ideal for smaller connections, usually supporting 3 to 7 pins.

- GX16: One of the most widely used—supports 2 to 12 pins, balancing size and capacity.

- GX20, GX25, GX30: Larger sizes offering more pins (up to 19) and higher current ratings for demanding applications.

These connector plugs are available in male and female variants. Male connectors typically have protruding pins, while female connectors have receptacles. You’ll find options for both panel mount connectors, which attach securely to surfaces, and cable end connectors for flexible wiring.

Many aviation plugs come with waterproof versions rated anywhere between IP65 and IP68, making them resistant to dust, water spray, and even submersion. This makes waterproof aviation connectors perfect for marine, outdoor, and rugged industrial environments.

For those requiring high-end performance, true mil-spec connectors, such as the MIL-DTL-38999 equivalent, offer military-grade durability, vibration resistance, and sealing ability. However, these typically come with a premium price tag, which might not be necessary for all applications.

Here’s a quick-reference table outlining typical GX aviation plug specs:

| Connector Type | Size (mm) | Pin Count | Voltage Rating | Current Rating | Waterproof Rating |

|---|

| GX12 | 12 | 3-7 | Up to 250V | Up to 7A | IP65/IP67 |

| GX16 | 16 | 2-12 | Up to 380V | Up to 10A | IP65/IP67 |

| GX20 | 20 | 3-12 | Up to 500V | Up to 20A | IP67/IP68 |

| GX25 | 25 | 7-16 | Up to 600V | Up to 25A | IP67/IP68 |

| GX30 | 30 | 12-19 | Up to 690V | Up to 35A | IP68 |

This variety means you can choose exactly the right combination of size, pin configuration, and durability for your specific project.

For a wider range of GX connectors and related circular aviation connectors, check out dedicated suppliers like wilmall aviation connectors who offer quality products and detailed specs to guide your choice.

Technical Specifications to Consider

When choosing an aviation connector plug, knowing the key technical specs helps ensure the right fit and reliable performance.

Pin Configurations and Voltage/Current Ratings

- Aviation plugs come with different pin counts, commonly from 2 up to 20 pins.

- More pins allow multiple signals or power lines in one connector.

- Typical current ratings range from 3A to 10A per pin, and voltage ratings usually reach up to 250V.

- For instance, a 5-pin aviation plug is popular for balanced power and signal transmission.

| Pin Count | Max Current (A) | Max Voltage (V) | Typical Use |

|---|

| 2–3 | 3–5 | 150–250 | Low-power signals |

| 5–8 | 5–7 | 250 | Power + signal combos |

| 10+ | 7–10 | 250 | Complex multi-signal setups |

Shell Materials

- Metal shells (usually aluminum or zinc alloy) offer ruggedness, shielding, and durability—ideal for metal aviation sockets in tough environments.

- Plastic shells mean lighter weight and cost savings but less protection against mechanical stress.

Contact Types

- Contacts come in solder, crimp, or PCB-mount styles.

- Solder contacts provide solid electrical connection but require careful heat application.

- Crimp contacts offer faster, reliable wiring with professional crimping tools.

Environmental Ratings

- Waterproof aviation connectors are rated from IP65 up to IP68, meaning protection against dust, water jets, and submersion.

- Vibration resistance, temperature range, and corrosion resistance also matter, especially for outdoor, marine, or industrial circular plug applications.

Certification Considerations

- Some connectors mimic or approach MIL-DTL-38999 (mil-spec) standards but at a more affordable GX-series pricing.

- True mil-spec aviation plugs are essential in avionics and other high-criticality uses.

- Look for certificates like RoHS, CE, or UL depending on your market or product requirements.

By reviewing these specs clearly, you’ll pick the best GX16 aviation connector or other circular aviation plugs for your project or system.

For well-made options and detailed specs, check out the LD20 series aviation connector to find quality solutions with clear technical details.

Primary Applications and Industries

Aviation connector plugs are everywhere thanks to their durability and reliable connection. Here’s where they really shine:

Industrial Automation and Robotics: These rugged circular electrical connectors ensure machines communicate flawlessly even in harsh factory environments. Their resistance to vibration and dust makes them perfect for automation systems. For related gear, check out our guide on industrial remote control transmitters used alongside aviation connectors.

LED Lighting and Stage Equipment: Circular aviation plugs with waterproof and dustproof ratings are popular for stage lighting and sound systems, where secure, quick connections matter and conditions can get intense.

Marine and Outdoor Electronics: Waterproof aviation connectors (often rated IP65 to IP68) handle moisture, salt spray, and temperature shifts well, making them ideal for boats, outdoor sensors, and weather stations.

Power Distribution and Battery Systems: Aviation plugs with high current ratings and thread-locking keep power stable in electric vehicles, battery banks, and portable power setups.

Avionics and General Aviation: Naturally, aviation connectors fit perfectly in aircraft electronics for communications, instrumentation, and control systems due to their mil-spec roots and durability.

DIY Projects and Instrumentation: Hobbyists and engineers prefer GX series connectors in custom builds and test rigs for easy, reliable interconnections.

These connectors bridge reliability with versatility, powering everything from high-tech avionics to everyday industrial setups. For more on devices paired often with aviation connectors, explore our role and advantages of proximity switch sensors in industrial automation.

How to Choose the Right Aviation Connector Plug

Selecting the right aviation connector plug can be tricky, but focusing on key factors helps you get it right the first time. Here’s a simple step-by-step guide:

Step 1: Know Your Environment

- Indoor or Outdoor? Waterproof aviation connectors with IP65–IP68 ratings are best for outdoors or harsh conditions.

- Temperature & Vibration: Metal aviation sockets handle extreme heat and vibration better than plastic ones.

Step 2: Determine Pin Count and Size

- Count how many electrical contacts/pins you need, from 2 to 20+ depending on your project.

- Common GX series sizes: GX12 (small), GX16 (medium), GX20 (large). Make sure the plug fits the device or panel space.

Step 3: Waterproof and Dustproof Needs

- Choose sealed connectors for marine, outdoor, or industrial use. Waterproof GX connectors extend the life of your setup.

Step 4: Match Plug and Socket Genders

- Always pair male plugs with female sockets—avoid mixing to prevent connection issues.

- Decide if you want panel mount aviation plugs or cable end connectors based on installation needs.

Common Mistakes to Avoid

- Buying connectors without verifying voltage/current specs can cause failures.

- Ignoring compatibility with existing connectors leads to mismatched pins or sizes.

- Overlooking environmental ratings may shorten connector lifespan.

Quick Compatibility Tips

| Фактор | Tip |

|---|

| Pin Configuration | Confirm pin count matches on plug and socket |

| Size & Thread Type | Check GX series number and thread specifications |

| Voltage/Current Rating | Ensure specs meet or exceed your device’s requirement |

| Waterproof Rating | Match IP rating to environment needs (IP65–IP68 recommended for outdoors) |

| Material | Metal for rugged use; plastic for lightweight or cost-sensitive |

Choosing with these points in mind helps avoid costly replacements and downtime. For detailed specs on GX series aviation connectors, explore wilmall’s extensive aviation connector range.

Installation and Wiring Guide for Aviation Connector Plugs

Installing an aviation connector plug correctly is key to reliable performance, whether you’re working with a GX16 aviation connector or a waterproof aviation connector variant. Here’s a simple guide to get you through the process smoothly:

Tools Needed

- Precision wire strippers

- Crimping tool or soldering iron (depending on contact type)

- Small flathead screwdriver (for tightening screws)

- Multimeter (for testing continuity)

- Heat shrink tubing or electrical tape for insulation

Wiring Techniques

- Strip wires carefully: Remove just enough insulation to fit into the contact without exposing extra wire.

- Crimp or solder contacts properly: For circular aviation connectors, soldered contacts make a solid connection, but crimp contacts are faster and reliable if done well.

- Double-check pin order: Use a wiring diagram specific to your plug’s pin configuration (like aviation plug 5 pin setups) to avoid mix-ups.

- Insert contacts fully: Ensure each wire is securely locked inside its contact and that the contact clicks into place inside the plug housing.

Best Practices for Secure Connections

- Match plug and socket genders correctly: Mismatching male and female connectors can cause damage or poor connections.

- Use the threaded locking mechanism to firmly secure aviation plugs—this prevents accidental disconnections.

- Apply heat shrink tubing over solder joints or crimps to protect against moisture and vibration.

- Test connections with a multimeter before final assembly. Check for continuity and proper insulation between pins.

Troubleshooting Tips

- If the device doesn’t power up, check pin wiring order and continuity again.

- Inspect for corrosion or dirt inside the metal aviation socket that might disrupt contact.

- Look for loose wiring or damaged contacts, especially in outdoor or rugged circular electrical connectors.

- If waterproofing is compromised, reseal using appropriate gaskets or replace the plug to maintain IP65–IP68 ratings.

For advanced remote control or industrial applications, you might want to explore related wiring setups within the industrial remote control transmitter sets available at wilmall.com, which often utilize similar aviation connector plugs.

Following these guidelines will help ensure your aviation connector plug installation is secure, durable, and ready for any demanding environment.

Maintenance and Longevity Tips for Aviation Connector Plugs

Keeping your aviation connector plugs in top shape means better performance and longer life. Here’s how to maintain your circular aviation connectors effectively:

Cleaning and Inspection Routines

- Regular cleaning: Use a soft brush or compressed air to remove dirt, dust, and debris from the connector’s pins and housing. Avoid harsh chemicals that can damage metal or plastic parts.

- Visual inspections: Check for corrosion, bent pins, or worn threads on the threaded circular connector. Look closely at waterproof aviation connectors for seal damage that could affect IP ratings.

- Contact cleaning: For stubborn oxide or grime buildup, use specialized electrical contact cleaners to ensure reliable connections.

Storage Recommendations

- Keep dry and dust-free: Store aviation connector plugs in sealed containers or bags when not in use to protect against moisture and dust.

- Avoid extreme temperatures: Keep connectors away from direct sunlight or freezing environments, which can degrade materials like rubber seals and plastics.

- Prevent physical damage: Store connectors with caps on the ends and avoid piling heavy objects on them to prevent deformation.

When to Replace Connectors

- Persistent corrosion or damage: If cleaning doesn’t restore connection quality or if corrosion has spread extensively, replacement is necessary.

- Damaged seals or threads: For waterproof GX connectors, compromised seals can lead to water ingress, causing failures—time for a new plug.

- Loose or broken pins: Damaged male or female aviation plugs can cause intermittent faults and must be replaced to maintain system safety.

- Frequent disconnections: Connectors that don’t lock firmly anymore should be swapped out to avoid accidental disconnections.

Proper maintenance ensures your aviation connector plugs continue to perform reliably across industrial, marine, and avionics applications. For hands-on wiring and installation tips, check out our detailed aviation plug wiring guide, designed to help you get secure and lasting connections.

Why Choose wilmall for Your Aviation Connector Needs

When it comes to finding reliable aviation connector plugs, wilmall stands out as a trusted supplier. Here’s why choosing wilmall is a smart move for your aviation connector requirements:

| Характеристика | What You Get from wilmall |

|---|

| Обеспечение качества | All products undergo strict quality checks to ensure durability and performance, including waterproof aviation connectors and rugged circular electrical connectors. |

| Wide Product Range | From popular GX series like the GX12, GX16, to waterproof GX connectors and metal aviation sockets, wilmall covers diverse industrial and DIY needs. |

| Competitive Pricing | Affordable pricing without compromising quality, perfect for projects large or small. |

| Fast Delivery | Reliable shipping with options for global customers, ensuring you get your aviation plugs on time. |

| Expert Support | Responsive customer service offering technical advice on specifications, wiring, and proper application to match your project requirements. |

wilmall’s focus on quality and variety makes it easy to find the right aviation plug, whether you’re working on industrial automation, outdoor electronics, or avionics systems. Plus, with detailed product info like aviation connector specifications and real-world installation guides, you can make confident choices every time.

Explore our selection of GX series connectors on wilmall to discover the perfect fit for your needs, including options suitable for harsh environments requiring waterproof and vibration-resistant plugs.

For a high-quality, dependable aviation connector plug supplier, wilmall is your go-to partner.