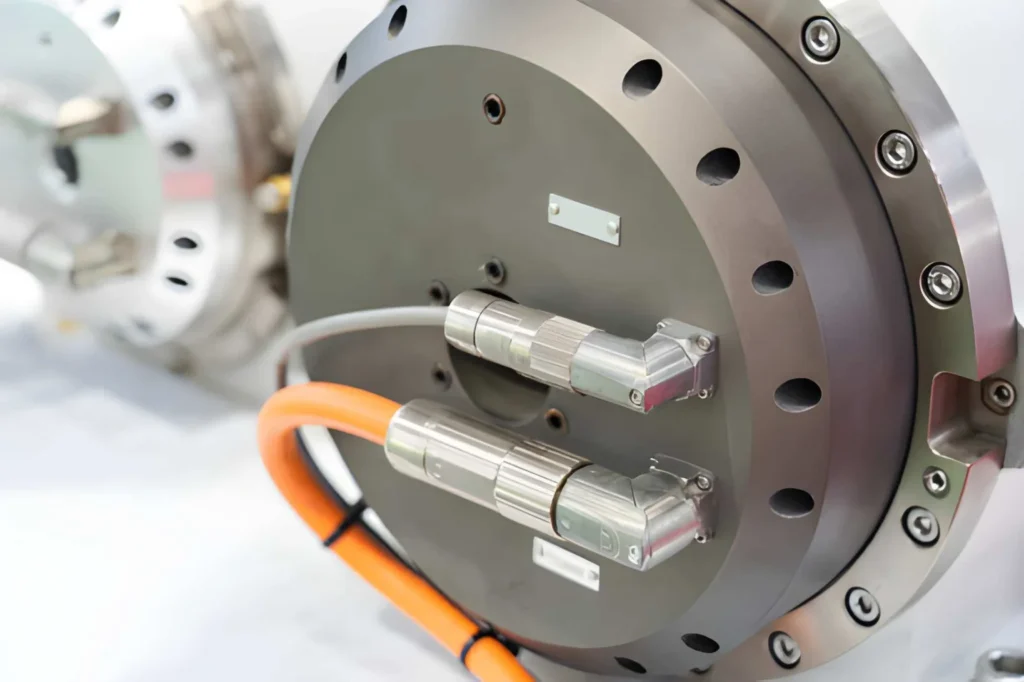

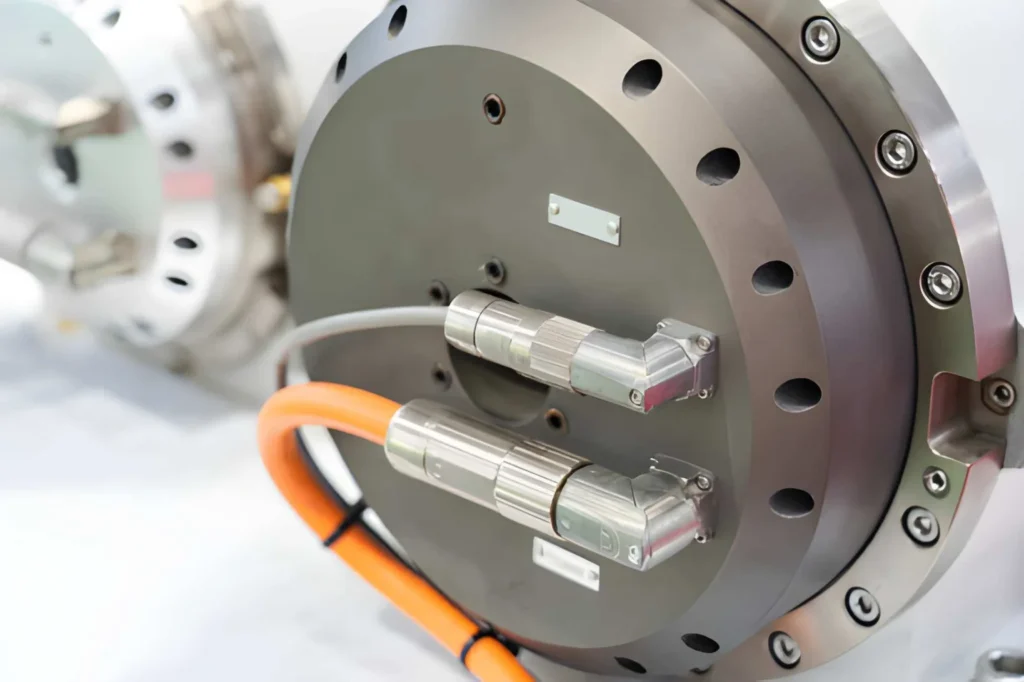

Aviation Plug Connector Durable Waterproof

What Is an Aviation Plug Connector?

Are you wondering what makes an aviation plug connector different from regular electrical connectors? Let’s break it down in simple terms.

Core Components of Aviation Plug Connectors

An aviation plug connector is a type of circular connector designed for reliable, secure electrical connections, especially in tough environments. Its main parts include:

| Компонент | Описание |

|---|---|

| Male/Female Plugs | Two halves that mate together securely |

| Pins | Metal contact points (2-pin to multi-pin) |

| Housing | Durable casing made of metal or plastic |

| Threaded Locking | Screw thread for tight, vibration-resistant coupling |

Сайт threaded locking system is crucial—it ensures the connector doesn’t come loose, even under vibration or movement.

How It Differs from Standard Electrical Connectors

Unlike typical push-pull or snap-fit connectors, aviation plug connectors are built to withstand:

- Vibration resistance: Threaded locks prevent accidental disconnection.

- Secure coupling: The metal or plastic housing protects internal contacts from impact or environmental damage.

- Environmental sealing: Many models offer dustproof and waterproof features (e.g., IP67/IP68 rated).

Origins and Evolution

Originally developed for the aviation and military sectors, these connectors met strict standards for safety and reliability in harsh conditions. Over time, their rugged design and secure performance made them popular in industrial applications, evolving into various grades suitable for factories, machinery, and electronics.

Key Features and Advantages of Aviation Plug Connectors

In , an aviation plug connector is a specialized, high-quality connection system with male/female plugs, sturdy pins, protective housing, and a threaded lock for security. Its roots in aviation and military standards ensure it meets tough vibration and environmental challenges better than everyday connectors.

Aviation plug connectors are built tough for demanding environments, combining durability with reliable electrical performance.

Durability and Environmental Protection

- Waterproof ratings: Commonly IP67 or IP68, meaning they are dust-tight and can handle immersion in water.

- Shock and vibration resistance: Designed to resist vibrations and impacts, making them perfect for industrial and outdoor uses.

- Dustproof sealing: Ensures connector integrity even in dusty or dirty conditions without compromising performance.

Secure Threaded Connection vs. Push-Pull

- Threaded locking mechanisms provide a sturdy, vibration-proof connection.

- Unlike push-pull connectors, aviation plugs won’t accidentally disconnect under stress.

- This ensures continuous power and signal transmission in critical applications.

Electrical Performance

| Характеристика | Типичный диапазон |

|---|---|

| Voltage rating | 250V–400V |

| Current rating | 5A to 20A and above |

| Contact resistance | Very low for minimal signal loss |

This ensures stable power delivery and efficient signal transfer.

Material Options

| Material | Benefits |

|---|---|

| Metal shell | EMI shielding, durability, heat resistance |

| Plastic shell | Lightweight, cost-effective, corrosion-resistant |

Metal shells are favored in industrial aviation plugs where electromagnetic interference (EMI) is a concern, while plastic connectors offer a budget-friendly alternative without sacrificing basic protection.

For those needing customization or specific industrial specifications, you can explore reliable solutions through trusted platforms offering aviation connector customization.

Overall, these features make aviation plug connectors ideal for harsh environments and critical electronic connections where durability and secure coupling matter most.

Common Types of Aviation Plug Connectors

Aviation plug connectors come in several popular series, each designed for various applications and pin counts. The most common series you’ll find include GX12, GX16, GX20, GX25, и GX30. The number in the series generally relates to the connector’s diameter size, with larger numbers offering more robust connections and greater pin counts.

Pin Count Options

These connectors range widely in pin configurations, often from 2-pin up to 10-pin or more. Multi-pin aviation plugs are perfect for transmitting power and signals in a single connector, helping to reduce wiring complexity. For example:

- GX12 connector 4 pin is popular for lightweight industrial devices.

- Higher pin counts are common in marine or renewable energy systems needing multiple signals or power lines.

Mounting Styles

You can choose between various mounting types:

- Panel mount aviation sockets let you securely attach connectors to control panels or enclosures.

- Cable-to-cable connectors are convenient for flexible wiring setups.

- You’ll also find connectors in both straight и right-angle designs, depending on space constraints and wiring direction.

Specialized Variants

Many manufacturers also offer specialized models tailored to specific needs such as:

- Waterproof aviation connectors with IP67 or IP68 ratings, ideal for harsh environments prone to dust and water exposure.

- High-current models to handle greater voltage and amperage for industrial automation and heavy equipment.

These variations make aviation plug connectors versatile and reliable for many industries and environments.

For an idea of quality and waterproof solutions, you might want to check the SD13 series connectors known for durability and secure connections in tough conditions.

Technical Specifications to Consider

When choosing an aviation plug connector, knowing the technical details is crucial to ensure a reliable and safe connection. Here are the key specs to keep in mind:

| Технические характеристики | На что обратить внимание |

|---|---|

| Pin Configurations | From 2-pin up to 10 pins (or more) – check wiring diagrams for proper connections and function. Multi-pin aviation plugs must match your device needs. |

| Rated Voltage | Typically between 250V and 400V. Ensure it suits your power requirements. |

| Rated Current | Usually ranges from 5A to over 20A, depending on the connector series and pin size. |

| Operating Temperature | Check the operating range, commonly from -40°C up to 85°C, especially important for harsh environments. |

| Environmental Ratings | Look for IP67 or IP68 ratings for waterproof and dustproof protection in demanding conditions. |

| Compatibility & Mating Cycles | Verify connector series and threading to avoid mismatches. Most aviation connectors support thousands of mating cycles, ensuring long-term durability. |

Choosing a connector with proper specifications avoids issues like overheating, poor contact, or environmental failures. For example, an IP68 aviation connector offers superior protection in damp or outdoor settings.

If you’re looking for detailed wiring and configuration options, suppliers like Wilmall’s pendant control stations provide practical examples and guides for industrial-grade aviation connectors.

Selecting the right specs ensures your aviation connector performs reliably, whether for industrial automation or rugged outdoor use.

Применение и отрасли

Aviation plug connectors are widely used across many industries thanks to their reliability and rugged design. In industrial automation and machinery, these connectors ensure secure, vibration-resistant connections for control systems and heavy equipment. You’ll find them in assembly lines, robotic arms, and industrial sensors where durability is key.

For electronics and DIY projects, such as 3D printers and robotics, aviation connectors offer a neat, professional solution for wiring complex setups. Their multi-pin versions allow easy connections that can handle power and data signals simultaneously.

In audio/video equipment and LED lighting, aviation connectors provide stable, low-resistance connections that maintain signal clarity. Their secure threaded locking prevents accidental disconnections in stage lighting, professional cameras, and sound systems.

They are also common in power systems, renewable energy, and marine environments, where waterproof aviation connectors with IP67 or IP68 ratings resist dust, moisture, and corrosion. This makes them ideal for solar installations, wind turbines, boats, and other harsh surroundings.

Finally, the connectors have found a place in modern consumer electronics. From rugged outdoor gadgets to specialty computers, their compact, circular metal body suits devices needing durable, multi-pin cable connections.

For industrial control solutions, you might be interested in pendant control stations that often use aviation connectors to maintain dependable remote operation.

No matter the field, aviation plug connectors offer a blend of robustness and versatility that modern applications demand.

How to Choose the Right Aviation Plug Connector

Picking the right aviation plug connector is easier when you follow these simple steps:

Step-by-step Selection Guide

| Step | What to Check |

|---|---|

| 1. Pin Count | Match the number of pins to your wiring needs. |

| 2. Environment | Choose waterproof (IP67/IP68) if exposed to dust, water, or shock. |

| 3. Cable Size | Confirm the connector fits your cable diameter for a secure fit. |

| 4. Thread Type | Make sure threads match between male and female parts to avoid fitting issues. |

| 5. Electrical Ratings | Verify voltage and current specs fit your application (usually 250V–400V, 5A–20A+). |

Common Mistakes to Avoid

- Using connectors with mismatched threading—can cause loose connections or damage.

- Picking connectors with underrated current ratings—leads to overheating or failure.

- Overlooking environmental protections—some jobs need waterproof aviation connectors to last.

Waterproof vs. Standard: When to Upgrade

- Upgrade to waterproof if the connector faces moisture, dust, or rough handling.

- For indoor or dry environments, standard aviation connectors work fine and save cost.

Budget vs. Premium Considerations

| Aspect | Budget Connector | Premium Connector |

|---|---|---|

| Material | Plastic housing | Metal shell with EMI shielding |

| Долговечность | Basic shock and dust resistance | High resistance to shock, dust, and water (IP67/IP68) |

| Price | Lower | Higher, reflects better specs and life |

| Приложения | Light-duty electronics or DIY | Industrial machinery, harsh environments |

Choosing depends on your project’s demands and budget balance. If you want reliable, durable connectors with options like GX16 aviation connector or high-pin count models, check out quality waterproof aviation connectors with competitive pricing.

This guide helps you avoid typical issues and pick the perfect aviation cable connector for your exact needs.

Installation and Wiring Guide for Aviation Plug Connectors

Installing an aviation plug connector properly ensures a reliable and safe connection. Here’s a quick guide on what you need and how to do it right.

Tools Required and Safety Precautions

- Tools: Wire strippers, soldering iron or crimping tool, screwdriver, multimeter for testing, and heat shrink tubing.

- Safety: Always disconnect power before working on any wiring. Wear protective eyewear and work in a well-ventilated area when soldering.

Step-by-Step Soldering and Crimping Instructions

- Prepare the wires: Strip about 5-7mm of insulation from each wire end.

- Identify pins: Refer to the aviation connector specifications or wiring diagram to match each wire to its correct pin.

- Soldering: Tin the wires and pins lightly. Heat the pin and wire together, applying solder until fully coated. Avoid cold joints by ensuring the solder flows smoothly.

- Crimping: If using crimp contacts, insert the stripped wire into the contact and use a crimping tool to secure it. Check for a firm grip without damaging the wire.

- Assemble: Insert the wired pins into the connector housing until they click or lock in place.

Testing for Continuity and Secure Connection

Before final assembly:

- Use a multimeter to test continuity between the pins and wires, ensuring proper connection.

- Check for shorts between adjacent pins.

- Once confirmed, tighten the connector’s threaded locking mechanism to secure the connection. This helps maintain strong electrical contact and vibration resistance typical of aviation cable connectors.

Troubleshooting Common Issues

- Loose pins: Ensure pins are fully seated and locked in the housing; reseat if necessary.

- Poor contact: Check solder joints or crimps—rewire if suspect.

- Cable strain: Avoid sharp bends near the connector; use strain relief options if possible.

Following these steps will keep your aviation plug connector safe and durable in demanding environments. For more detailed advice on cable sealing, checking cable gland installation guides can be helpful when pairing connectors with cable protection.

Buying Guide: Pricing, Suppliers, and Recommendations

When shopping for an aviation plug connector, prices can vary widely depending on type, pin count, and features. For example, simple 2-pin connectors tend to be affordable, while multi-pin models like the GX16 or GX20 series typically cost more. Expect basic connectors to start around a few dollars each, with waterproof aviation connectors or industrial aviation plugs priced higher due to enhanced materials and protection levels like IP67 or IP68 ratings.

Key factors influencing cost include:

- Material: Metal shells with EMI shielding usually cost more than plastic ones but offer better durability.

- Waterproofing: Connectors rated IP67/IP68 command a premium for their dust and water resistance.

- Brand reputation: Established aviation connector suppliers often charge more but provide reliable quality and certifications.

Top suppliers usually have a broad range of circular metal connectors and threaded aviation connectors available. For dependable sourcing, wilmall stands out with a solid selection of quality waterproof aviation connectors, competitive prices, and consistent availability. Their offerings include panel mount aviation sockets and multi-pin aviation plugs ideal for industrial or DIY projects.

Tips for buying:

- Buy in bulk to lower unit costs, especially if you need multiple GX12 or GX25 connectors.

- Always verify the authenticity of aviation connectors from your supplier to avoid counterfeit or low-quality parts.

- Match connectors precisely by pin count and threading to ensure compatibility and secure connections.

For a reliable source offering robust aviation cable connectors and more, check out wilmall’s SD20 series connectors and related products that cater well to harsh environment connectors and industrial setups. This ensures you get both quality and value with every purchase.

Maintenance, Care, and Best Practices

Keeping your aviation plug connector in top shape means regular cleaning and proper storage. Dirt, dust, and moisture can affect connections over time, so wipe the connectors with a soft, dry cloth after use, especially for waterproof aviation connectors exposed to harsh environments. Avoid using harsh chemicals that might damage seals or metal parts.

To extend the lifespan of industrial aviation plugs, store them in a dry, cool place when not in use. If they’re part of outdoor or marine equipment, inspect for corrosion or wear regularly and apply appropriate protective sprays if recommended.

Signs it’s time to replace your aviation connector include:

- Loose or bent pins causing poor contact

- Cracked or damaged housing

- Thread wear making secure locking difficult

- Corrosion or rust on metal parts affecting conductivity

Regular maintenance and timely replacement ensure safety and reliable performance, especially in demanding industries. For high-quality options that are durable and waterproof, consider reliable brands like those found at wilmall’s waterproof aviation connector collection.