El encóder rotativo incremental GOS38A04 está diseñado para proporcionar información precisa sobre el movimiento y la posición en entornos de automatización industrial exigentes. Con un robusto eje de 38 mm y una resolución personalizable de hasta 600 impulsos por revolución (PPR), este encóder proporciona señales AB en cuadratura fiables y precisas, ideales para aplicaciones de detección de velocidad, posición y dirección. Diseñado para durar, el encóder admite una instalación versátil con una construcción robusta y señales de salida estables, lo que garantiza un rendimiento duradero en diversos sistemas de automatización y control de movimiento.

Características principales

Eje macizo de 38 mm de diámetro para uso intensivo

Resolución personalizable de hasta 600 PPR para una medición precisa

Señales de salida en cuadratura AB estándar con alta inmunidad al ruido

Construcción robusta apta para entornos industriales

Admite la detección de rotación en sentido horario y antihorario

Pulso cero opcional (canal Z) para el marcado de referencia y la referenciación

Ventajas del producto

La alta precisión y repetibilidad aumentan la fiabilidad del sistema

Diseño mecánico duradero resistente a vibraciones y golpes

Opciones de salida flexibles que facilitan la integración con PLC, controladores y accionamientos industriales

Larga vida útil y rendimiento estable en condiciones adversas

El bajo par de arranque reduce el desgaste y prolonga la vida útil de la caja de cambios y el motor

Solución rentable de fácil mantenimiento

Modelo de producto y significado

| G | 0 | S | 38 | □ | A | 04 | 1000 T | 3 | 2M | ||||

| Categoría producto | Tipo de producto | Forma de eje principal | Contorno de producto | Tamaño del principal eje, agujero del eje | Salida y formulario de sellado | Esquema de la estructura | Resolución | Formulario de salida | Señal de salida | Cable | |||

| G:incremental tipo | 0:megneto- electricidad | S:eje macizo | 38:φ38mm | □:φ6mm | A:goma de salida lateral | 04:4 esquema estructura4 | 10,20,50, 60,100, 200,360, 400,500 600,800, 1000,1024,1200, 2000,2048,2500,3000,3600, 4096 | T:salida push pull L:Salida de 5 V A:Salida de 24 V | 1Afase Asignal 2:ABseñal de fase AB 3:ABZfase Señal ABZ 4:fase Señal ABA/B/ 5:fase ABZA/B/Z/ señal | Por defecto 2m línea,Para no 2m, el etiquetado es suficiente | |||

Tabla de cableado

| Color de la línea | T señal de salida | – | Color de la línea | Señal de salida L/A |

| marrón | VCC | marrón | VCC | |

| azul | GND | |||

| azul | GND | |||

| negro | Una fase | |||

| negro | Una fase | blanco | Fase B | |

| naranja | Fase Z | |||

| blanco | Fase B | |||

| negro rojo | Aphase | |||

| naranja | Fase Z | blanco rojo | Bphase | |

| rojo anaranjado | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

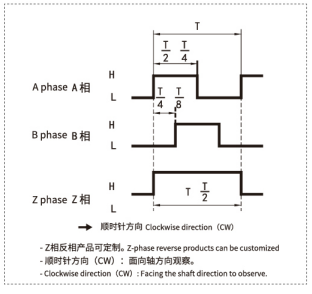

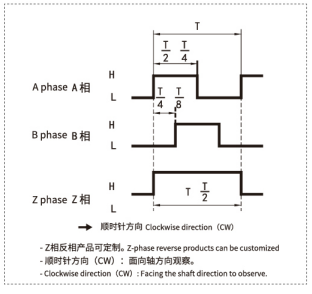

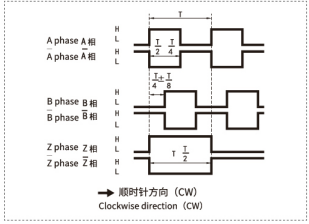

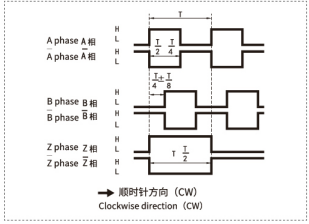

Diferencia de fase de salida

salida push pull

salida de palangre

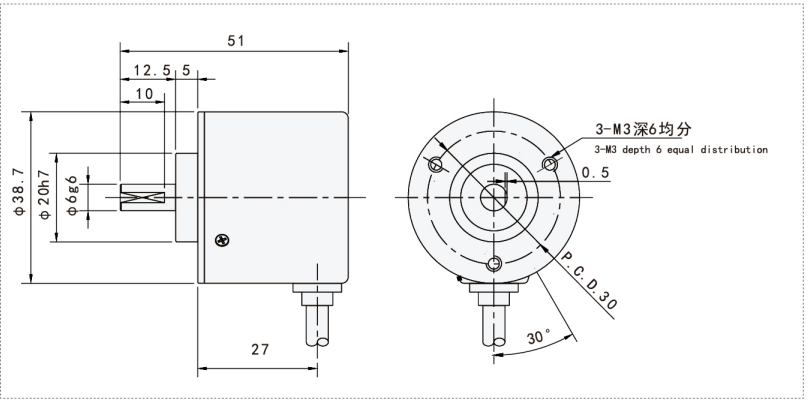

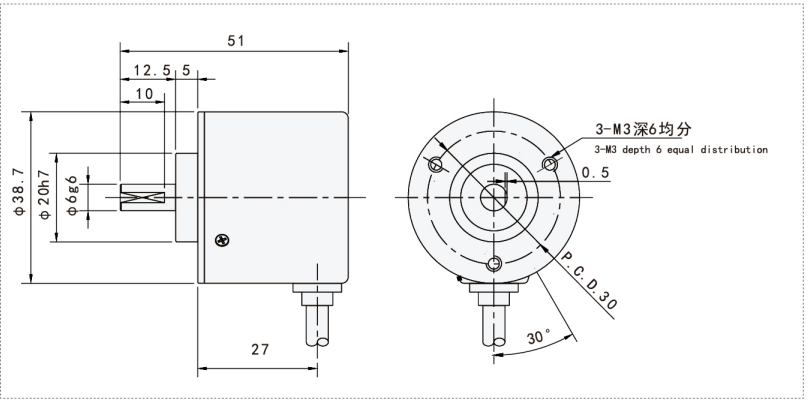

Dibujos mecánicos(mm)

Pasos de la instalación y mantenimiento

Fije firmemente el eje del codificador al eje del equipo giratorio, asegurando una alineación correcta para evitar tensiones mecánicas.

Conecte los cables de salida del codificador a las entradas de su sistema de control, verificando el cableado según las especificaciones de señal de ABZ.

Establezca la resolución y el recuento de impulsos deseados si dispone de personalización; de lo contrario, utilice los ajustes predeterminados de fábrica.

Realice las pruebas iniciales de rotación para confirmar la salida de señal y la precisión de detección de dirección.

Inspeccione periódicamente el codificador y las conexiones en busca de suciedad, residuos o desgaste y límpielos con cuidado para mantener un funcionamiento óptimo.

Lubrique los rodamientos si se especifica en el manual de usuario (la mayoría de los modelos están sellados y no requieren mantenimiento).

Aplicaciones

Automatización industrial y robótica que requieren información precisa sobre la posición angular

Maquinaria CNC para posicionamiento de herramientas y control de velocidad

Sistemas de transporte y máquinas de envasado para una supervisión precisa del movimiento

Maquinaria de impresión para la detección sincronizada de velocidad y posición

Instrumentación de dispositivos médicos que requiere retroalimentación rotativa de alta precisión

Ascensores y escaleras mecánicas para verificar la posición del motor

Solicite un presupuesto ahora

Nuestro equipo se pondrá en contacto con usted en un plazo de 24 horas.