El encóder rotativo incremental GLS45C proporciona información de posición y velocidad precisa y estable para una amplia gama de aplicaciones de automatización industrial. Diseñado para ofrecer durabilidad y precisión, este encóder admite varias señales de salida y cuenta con una construcción mecánica robusta para soportar entornos operativos difíciles, lo que lo convierte en una opción fiable para sistemas avanzados de control de movimiento.

Características principales:

Salida incremental de alta resolución con señales de impulsos estables

Diseño compacto y robusto para uso industrial

Múltiples opciones de salida, incluidas TTL y colector abierto

Fácil instalación con brida de montaje y acoplamiento de eje normalizados

Rodamientos duraderos y diseño sellado para mayor durabilidad

Amplia gama de tensión de alimentación adaptable a diferentes sistemas

Ventajas del producto:

Garantiza una respuesta rotacional precisa para mejorar la precisión del control

Su robusta construcción minimiza los tiempos de inactividad y los costes de mantenimiento

Compatibilidad versátil con diversos sistemas de control industrial

Mejora el rendimiento de las máquinas en líneas de producción automatizadas

Permite una instalación flexible en espacios reducidos

Modelo de producto y significado

| G | L | S | 45 | C | 1000 | C | 3 | 2M | |||

| Categoría producto | Tipo de producto | Forma de eje principal | Contorno de producto | Salida y formulario de sellado | Resolución | Formulario de salida | Señal de salida | Cable | |||

| G:incremental tipo | L:fotoelec- tricidad | S:eje macizo | 45:φ45mm | C:salida trasera | 10,20,50,60,100,200,360, 400,500,600,800, 1000,1024,1200,2000,2048,2500, 3000,3600,4096 | C: colector abierto salida F: complementario salida L:Salida de 5 V | 1:señal de fase A 2:señal de fase AB 3:fase Señal ABZ 4:fase ABA/B/ señal 6:fase ABZA/B/Z/ señal | Por defecto 2m línea,Para non 2m, etiquetado es suficiente | |||

Tabla de cableado

| Color de la línea | Señal de salida C/F | – | Color de la línea | Señal de salida |

| rojo | VCC | rojo | VCC | |

| negro | GND | |||

| negro | GND | |||

| verde | Una fase | |||

| verde | Una fase | blanco | Fase B | |

| amarillo | Fase Z | |||

| blanco | Fase B | |||

| rosa | Aphase | |||

| amarillo | Fase Z | azul | Bphase | |

| naranja | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

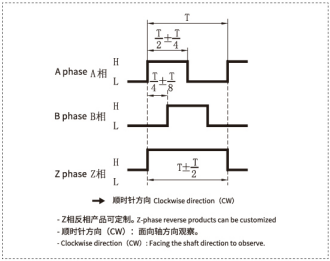

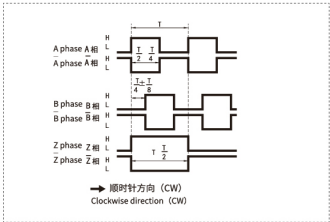

Diferencia de fase de salida

salida complementaria/colector NPN salida en circuito abierto

salida long line drive

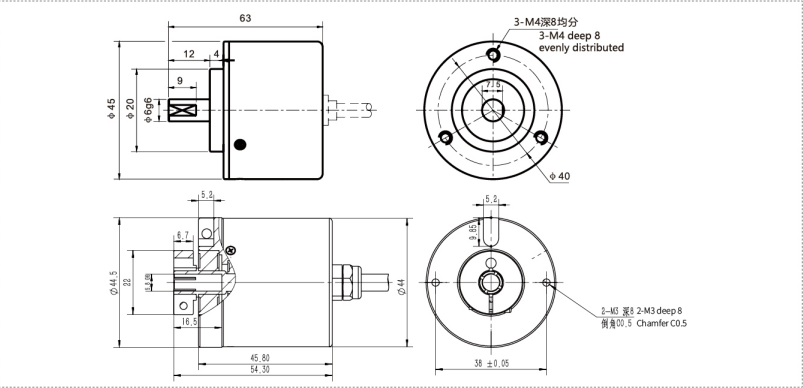

Dibujos mecánicos(mm)

Pasos de instalación y mantenimiento:

Monte el codificador GLS45C de forma segura en el eje del motor o de la máquina utilizando el acoplamiento adecuado.

Alinee con precisión el eje del codificador con el eje de transmisión para evitar tensiones mecánicas.

Conecte el cableado de acuerdo con el diagrama de cableado detallado, asegurándose de que la alimentación y la configuración de las señales son correctas.

Pruebe las señales de salida del codificador para verificar el funcionamiento correcto con el sistema de control.

Inspeccione regularmente el codificador para detectar la presencia de polvo, los efectos de las vibraciones y el desgaste mecánico.

Realice la limpieza rutinaria y la lubricación si es necesario, siguiendo las directrices del fabricante.

Aplicaciones detalladas del producto:

Automatización industrial y líneas de fabricación que requieren un control preciso del movimiento

Maquinaria CNC para retroalimentación de posición y regulación de velocidad en tiempo real

Robótica en la que la detección precisa de la posición del eje es fundamental para el funcionamiento

Transportadores y sistemas de manipulación de materiales para controlar la velocidad y el flujo

Máquinas de impresión y envasado para sincronización y control de procesos

Sistemas de ascensores para garantizar un control suave y seguro de la rotación de los huecos

Aerogeneradores y sistemas de energías renovables para medir la posición de las palas

Productos sanitarios en los que la precisión y la fiabilidad son esenciales

Solicite un presupuesto ahora

Nuestro equipo se pondrá en contacto con usted en un plazo de 24 horas.