El encóder rotativo GOS5008B se ha diseñado para proporcionar una respuesta rotacional robusta y fiable, garantizando un rendimiento constante en entornos exigentes. Con un diseño robusto y opciones de salida versátiles, este encóder ofrece señales precisas de velocidad y posición esenciales para diversas aplicaciones de automatización y maquinaria. Diseñado para un uso intensivo, permite mejorar la supervisión y el control del movimiento con unos requisitos de mantenimiento mínimos.

Características principales:

Salida incremental de alta resolución que proporciona señales de impulsos estables y coherentes

Carcasa robusta, resistente al polvo y a las vibraciones para una mayor durabilidad

Admite múltiples formatos de salida, incluidas señales TTL y de colector abierto

Montaje con brida estándar y acoplamiento de eje para una instalación fácil y segura

Carcasa sellada y rodamientos de alta calidad para prolongar la vida útil

Amplia gama de tensiones para una integración perfecta con distintas fuentes de alimentación

Ventajas del producto:

Proporciona información fiable y constante para optimizar la precisión del movimiento de la máquina.

Construcción resistente que minimiza el tiempo de inactividad por desgaste y condiciones duras

Las opciones flexibles de salida y montaje simplifican la integración del sistema

Mejora el rendimiento de la máquina garantizando datos de movimiento precisos y en tiempo real

Tamaño compacto que se adapta fácilmente a espacios reducidos sin comprometer el rendimiento

Modelo de producto y significado

| G | 0 | s | 50 | 06 | B | 1000 | c | 3 | 2M | |||

| Categoría producto | Tipo de producto | Forma del eje principal | Contorno de producto | Tamaño del eje principal, orificio del eje

| Salida y formulario de sellado | Resolución | Formulario de salida | Señal de salida | Cable | |||

| G:tipo incremental | 0:megneto electricidad L:fotoelec- tricidad | S:eje macizo | 50:φ50mm | □:φ8mm 06:φ6mm | E:salida lateral metálica D:salida trasera metálica | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:salida de colector abierto F:salida complementaria T:salida push pull L:Salida de 5 V A:Salida de 24 V | 1: fase Asignal 2: señal de fase AB 3:fase Señal ABZ 4:fase Señal ABA/B/ 5:fase ABZA/B/Z/ señal | Por defecto 2m lne,For non 2m, labeing es suficiente |

Tabla de cableado

| Color de la línea | Señal de salida C/F/T | Color de la línea | Señal de salida L/A | |

| rojo | VCC | rojo | VCC | |

| negro | GND | |||

| negro | GND | |||

| verde | Una fase | |||

| verde | Una fase | blanco | Fase B | |

| amarillo | Fase Z | |||

| blanco | Fase B | |||

| marrón | Una fase | |||

| amarillo | Fase Z | gris | Bphase | |

| naranja | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

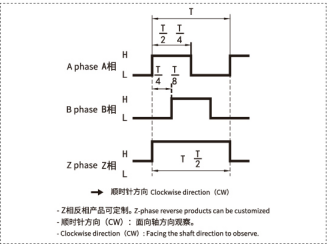

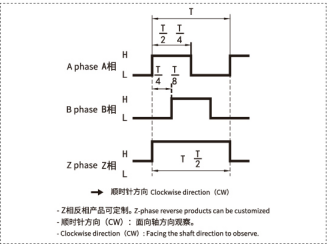

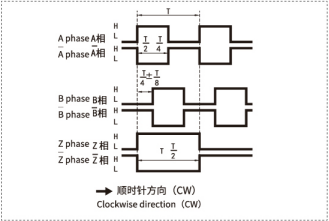

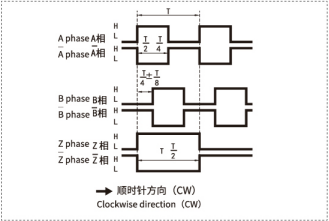

Diferencia de fase de salida

salida complementaria/push pull salida/colector NPN salida en circuito abierto

salida de palangre

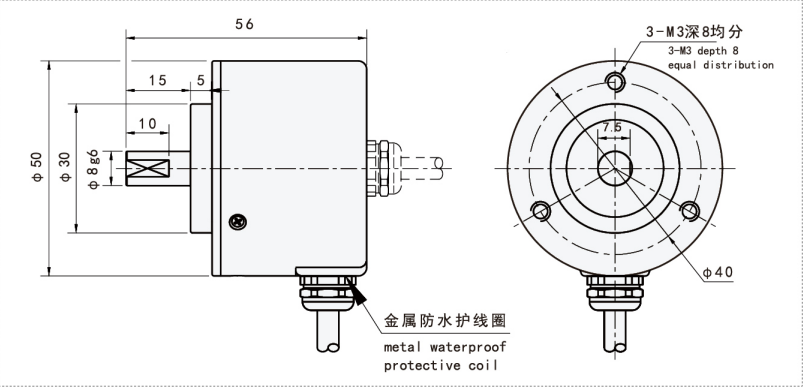

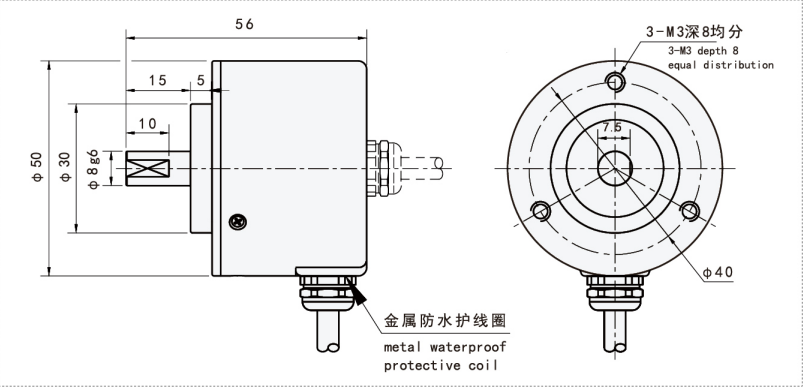

Dibujos mecánicos(mm)

Instalación y mantenimiento:

Monte el encoder GOS5008B de forma segura en el eje del equipo utilizando el acoplamiento o adaptador suministrado.

Garantice una alineación precisa del eje para evitar el desgaste mecánico y la distorsión de la señal.

Conecte el cableado de acuerdo con el esquema suministrado, verificando que todas las conexiones sean correctas.

Pruebe las señales de salida con su sistema de control o supervisión antes del funcionamiento completo.

Limpie periódicamente la carcasa del codificador para eliminar la acumulación de polvo y residuos.

Inspeccione periódicamente los herrajes de montaje, los acoplamientos mecánicos y los conectores eléctricos; lubrique los componentes según se recomiende.

Aplicaciones detalladas del producto:

Ideal para entornos resistentes y sensibles, el encóder rotativo GOS5008B es perfecto para:

Sistemas de manipulación y transporte de materiales que requieren un control preciso de la velocidad y la posición

Brazos robóticos y maquinaria automatizada que exigen una respuesta de movimiento coherente

Equipos de envasado e impresión para una sincronización y un control de calidad precisos

Sistemas de ascensores y escaleras mecánicas para garantizar rotaciones de hueco suaves y seguras

Sistemas de energías renovables, como las turbinas eólicas, para el posicionamiento de las palas y la detección de la velocidad.

Maquinaria agrícola y de construcción que funciona en condiciones exteriores adversas

Dispositivos médicos e instrumentos de laboratorio que requieren datos de rotación fiables

El GOS5008B forma parte de una categoría más amplia de encóderes rotatorios incrementales que han avanzado significativamente en tecnología, centrándose en mejorar la durabilidad y la integridad de la señal en entornos difíciles. Estos encóderes desempeñan un papel crucial en la automatización inteligente al proporcionar datos de rotación en tiempo real que repercuten directamente en la precisión y la eficacia del sistema. Conocer las prácticas de instalación y las rutinas de mantenimiento adecuadas es clave para maximizar el rendimiento y la longevidad de los encóderes. Además, las innovaciones en los materiales de los encóderes y las tecnologías de sellado siguen ampliando los límites de su aplicación, lo que abre las puertas a su uso en condiciones extremas, como la producción de energía en alta mar y la maquinaria pesada en operaciones mineras.

Solicite un presupuesto ahora

Nuestro equipo se pondrá en contacto con usted en un plazo de 24 horas.