Hollow Rotary Encoder High Precision Through-Bore Sensor

Índice

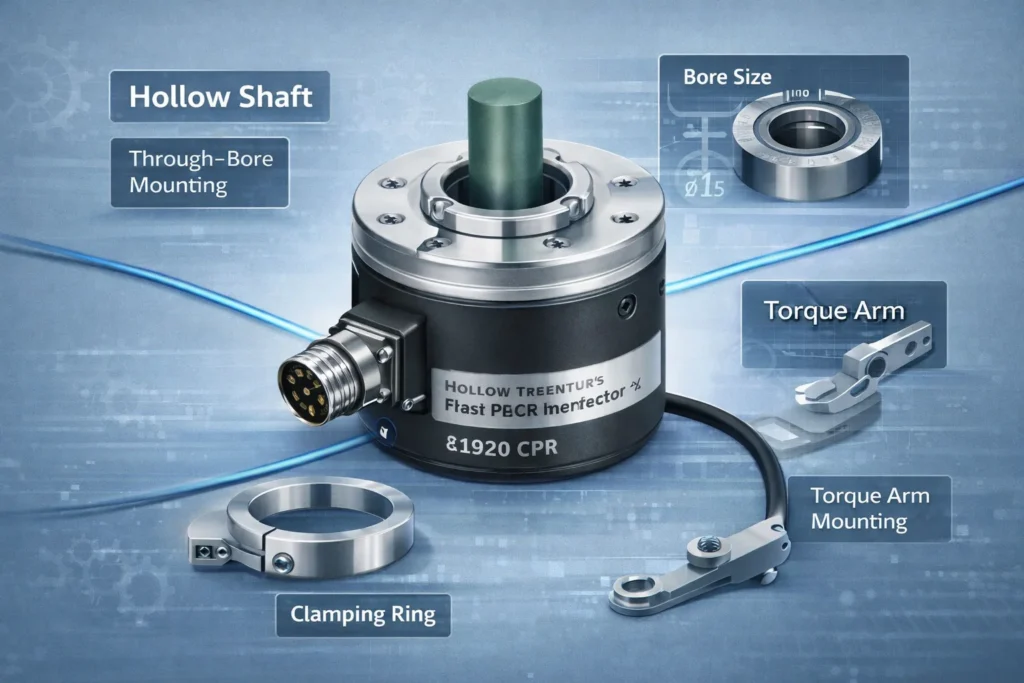

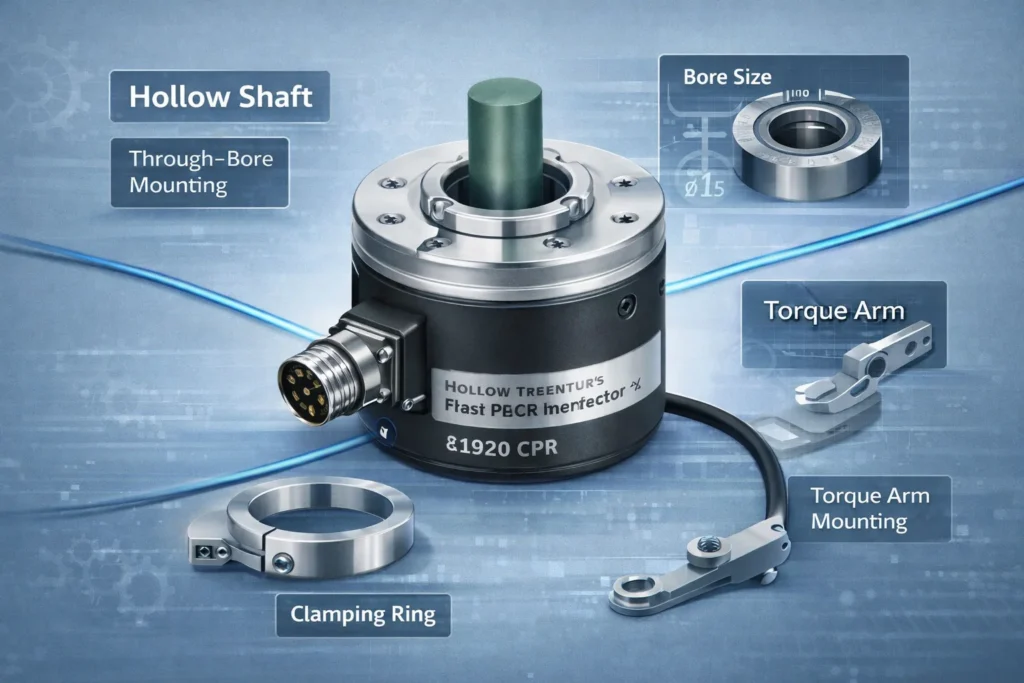

Wilmall hollow rotary encoders offer high precision, flexible bore sizes, clamping ring mounting, and durable design for industrial automation.

Hollow Rotary Encoder – Direct Shaft Mounting & Reliable Feedback

Wilmall’s hollow rotary encoder delivers precise, direct shaft mounting with a compact, space-saving design tailored for demanding industrial environments. Engineered for high concentricity and rugged use, it offers reliable feedback in harsh conditions without the need for couplings or complex installation.

A hollow shaft rotary encoder, also known as a through-bore encoder, fits directly over your motor shaft, providing accurate position and speed data while reducing mechanical complexity. Wilmall stands out through precision engineering, broad bore compatibility from 6mm to over 85mm, and robust construction that ensures long-lasting performance.

Select your bore size & resolution now or Request a Quote to tailor the perfect encoder solution for your application.

Key Features & Benefits of Wilmall Hollow Rotary Encoders

Our hollow rotary encoders feature a hollow shaft / through-bore design that clamps directly onto your motor shaft. This means no couplings needed, saving space and reducing mechanical errors.

Flexible mounting options include:

- Clamping ring for a secure, easy fit

- Torque arm or flexible tether options to prevent rotation and ensure stable positioning

We deliver high concentricity y low runout tolerance, which means more accurate feedback and less vibration error during operation. Our encoders fit a wide bore size range, from 6mm up to 85mm+, accommodating most standard motor shafts.

Choose from:

- Incremental or absolute versions depending on your feedback needs

- Optical or magnetic sensing technology, offering either super-high resolution or long-lasting durability

Built tough, our encoders come with industrial-grade protection ratings (IP54/IP65) to withstand dust, oil, and shock, perfect for harsh environments.

| Característica | Beneficio |

|---|---|

| Hollow shaft / through-bore | Direct shaft mounting, no couplings |

| Clamping ring mounting | Secure, easy installation |

| Torque arm/tether options | Anti-rotation stability |

| High concentricity & low runout | Accurate positioning, minimal vibration |

| Bore size range: 6mm to 85mm+ | Fits most motor shafts |

| Incremental & absolute types | Broad application flexibility |

| Optical & magnetic sensing | High resolution & durability |

| IP54/IP65 protection | Reliable in tough industrial use |

Explore our incremental rotary encoder guide to understand more about sensor types and applications.

This mix of precision, flexibility, and durability makes Wilmall hollow bore rotary encoders an ideal choice for demanding industrial feedback systems.

Technical Specifications of Hollow Rotary Encoders

Our hollow rotary encoders come with precise technical specs designed for reliable performance and easy integration. Here’s a quick rundown of key details:

| Característica | Specification Range / Details |

|---|---|

| Bore Diameter | 6mm to 85mm+ (custom sizes available) with tight tolerances |

| Outer Diameter | Varies by model, typically 40mm to 90mm |

| Resolution (PPR/CPR) | 100 to 10,000+ pulses per revolution |

| Output Types | Line driver (RS422), push-pull, open collector, voltage |

| Tensión de alimentación | 5V to 24V DC |

| Current Draw | Low current consumption suitable for industrial use |

| Max Shaft Speed | Up to 12,000 RPM depending on model |

| Frequency Response | High-speed output up to 300 kHz |

| Accuracy | High concentricity with runout under 0.02mm typical |

| Repeatability & Hysteresis | Minimal, ensuring reliable position feedback |

| Operating Temp. | -20°C to +85°C (industrial range) |

| Humidity & Protection | IP54 / IP65 options against dust, oil, and shocks |

| Cable & Connectors | Various lengths and connector types available |

| Housing Material | Durable aluminum with corrosion resistance |

| Weight | Lightweight design for easy mounting |

These specs make Wilmall’s hollow shaft rotary encoders reliable in tough industrial settings. For detailed mechanical dimensions and advanced sensor options, explore our precision incremental rotary encoders with IP67 protection.

This combination of wide bore compatibility, high concentricity, and flexible electrical outputs makes our hollow bore encoder solutions suitable for a broad range of motor shaft feedback applications.

Mounting & Installation Guide for Hollow Rotary Encoder

Installing your hollow rotary encoder correctly ensures precise feedback and long service life. Follow these simple steps for best results:

- Shaft Insertion: Slide the hollow shaft encoder directly over the motor shaft. Make sure the bore size matches your shaft diameter for a snug fit.

- Clamping Ring Tightening: Secure the encoder using the clamping ring. Tighten gradually and evenly using a calibrated torque wrench. Recommended torque values usually range between 0.5 to 1.5 Nm—check your specific model’s datasheet for accuracy.

- Torque Arm Attachment: Attach the torque arm or flexible tether to prevent rotation of the encoder housing during operation. This is critical to avoid slippage and ensure stable readings.

- Anti-Rotation Methods: Besides torque arms, pin stops or flexible tethers can be used depending on your application for secure mounting and preventing encoder housing movement.

- Alignment Tips for Concentricity: Align the encoder carefully to the motor shaft to maintain high concentricity and minimize runout errors. Even slight misalignment can affect accuracy and increase vibration.

Common Pitfalls & Troubleshooting

- Shaft Current Isolation: Ensure electrical isolation of the motor shaft if your setup is prone to shaft current. Use insulating sleeves or isolators to protect the encoder’s sensitive electronics.

- Over-Tightening: Avoid over-tightening clamping rings or mounting screws as it may deform the shaft or encoder housing, impacting performance.

- Runout Issues: Check for wobble or runout after installation—low runout rotary encoders depend heavily on precise mounting.

For more detailed installation help, consult our high-resolution rotary encoder technical resources, which offer in-depth guides tailored to various bore sizes and mounting options.

Applications of Hollow Rotary Encoders

Wilmal’s hollow rotary encoders are designed to deliver precise and reliable feedback in a wide range of industrial settings. They are ideal for servo motors and stepper motor feedback, ensuring smooth, accurate positioning in automation and motion control systems.

In robotic arms and joint control, these encoders provide the high concentricity and low runout needed for exact movement and repeatability. Their space-saving hollow shaft design fits directly over motor shafts, making installation straightforward and maintenance easier.

They are also widely used in conveyor systems, packaging machinery, and printing presses, where consistent speed and position data are critical to efficient operation. For heavy-duty applications, such as elevator/escalator drives, cranes, and wind turbines, the robust construction and industrial-grade protection make these encoders highly reliable even in harsh environments.

Additionally, Wilmal’s hollow shaft encoders meet the tough demands of CNC machines, textile equipment, and heavy industrial drives, where precision and durability are paramount.

For versatile mounting and secure installation, our encoders can be paired with accessories like torque arms and clamping rings, ensuring stability across all these applications—giving you dependable, accurate feedback no matter the task.

Explore compatible options with our GLS45C rotary encoder series for precise motor shaft feedback solutions.

Why Choose Wilmall Hollow Rotary Encoders

Wilmall hollow rotary encoders stand out for their superior build quality, focusing on low runout y long service life. Our encoders deliver precise, reliable feedback even in tough, high-vibration, or contaminated industrial environments.

Key Advantages at a Glance

| Característica | Beneficio |

|---|---|

| Low runout tolerance | Accurate positioning, less vibration |

| Broad bore size options | Fits motor shafts from 6mm to 85mm+ |

| Customizable resolution | From 100 to 10,000+ PPR |

| Output flexibility | Line driver, push-pull, open collector |

| Fast lead times | Quick delivery for urgent projects |

| Wide motor compatibility | Works with major motor brands |

| Robust environmental ratings | IP54/IP65 protection for harsh use |

With Wilmall, you get a tailored solution — select your bore size, output typey resolution to suit your unique application. Our expertise ensures seamless integration and durability.

For enhanced protection in demanding setups, consider pairing the encoder with our range of corrosion-resistant cable glands y industrial-grade connectors, like the stainless steel cable gland large diameter M32A, to ensure secure, long-lasting connections.

Choose Wilmall when you need a hollow bore rotary encoder that performs reliably, installs easily, and lasts longer under the toughest conditions.

Product Variants / Model Selector

Elegir bien hollow rotary encoder for your application is simple with our clear model selector. You can filter options by bore size, resolution, output type, and whether you need an incremental or absolute hollow shaft encoder.

Our selection covers a wide bore range, from small 6mm shafts up to large 85mm+ diameters, ensuring compatibility with most motor shafts. The selector helps you quickly narrow down key specs such as:

- Bore diameter and tolerance

- Resolution (from 100 to 10,000+ PPR)

- Output signals like line driver (RS422), push-pull, or open collector

- Optical or magnetic sensing options

We also provide an easy-to-use part number generator, so you can create custom configurations tailored to your exact needs without confusion. For quick reference, a model chart s popular combinations across clutch mounting types, output formats, and resolution levels.

This tool helps streamline your selection of through-bore rotary encoders and ensures you get the perfect fit for your motor feedback or industrial automation projects.

Accessories & Related Products

Enhance your hollow rotary encoder setup with our comprehensive range of accessories designed for easy installation and reliable operation. Our mounting kits include precision clamping rings, torque arms, and flexible tethers to ensure secure attachment and anti-rotation, matching the needs of through-bore rotary encoder installations.

You’ll also find high-quality cables, connectors, and mating plugs tailored for robust signal transmission and compatibility with various output types. For hybrid setups, we offer versatile couplings that allow seamless integration between hollow shaft and solid shaft systems.

In addition, explore related products like solid shaft encoders y draw-wire sensors, perfect for projects requiring different sensing solutions or backup systems. These accessories and related items support your entire control and feedback ecosystem, helping you achieve accurate, low runout performance every time.

Downloads & Resources

Access all the essential documents for Wilmall hollow rotary encoders in one place. Download the detailed datasheet PDF for complete technical specs, 2D and 3D CAD models for seamless integration into your design, and the installation manual to ensure correct mounting and setup.

Wiring diagrams are also available to guide you through proper electrical connections, while the declaration of conformity certifies compliance with industry standards. These resources support a smooth installation process and optimal performance of your hollow shaft rotary encoder.

FAQs about Hollow Rotary Encoders

What is the difference between hollow shaft and solid shaft encoders?

A hollow shaft rotary encoder fits directly over the motor shaft, allowing it to pass through the encoder (through-bore design), which saves space and reduces the need for couplings. Solid shaft encoders, on the other hand, have a fixed shaft that mounts parallel or inline but require additional couplings to connect to the motor shaft. Hollow bore encoders are simpler to install and offer better concentricity, ideal for compact or high-vibration applications.

How do I select the right bore size for my encoder?

Choose a bore size that matches your motor shaft diameter for a snug, direct fit. Wilmall hollow rotary encoders accommodate a broad bore range (6mm to 85mm+), so measure your shaft precisely. If you’re unsure, consider the tolerance and mounting ease. Our product pages help you select bore size and resolution to fit your exact needs.

What mounting method is best for my application?

The clamping ring mounting ensures a secure and vibration-resistant fit, ideal for most industrial uses. For applications with higher torque or strong vibrations, adding a torque arm or tether prevents rotation of the encoder housing. These anti-rotation options improve long-term reliability and accuracy by maintaining low runout. You can find related mounting accessories like torque arms and clamping rings to suit various setups.

How do I achieve low runout tolerance during installation?

To get the best concentricity and low runout, carefully align the encoder on a clean, smooth motor shaft. Tighten the clamping ring evenly using recommended torque settings and ensure anti-rotation devices like torque arms are properly installed. Avoid mixing materials that cause shaft current issues. Following these steps results in precise position feedback with minimal vibration error. For detailed guidance, check our mounting and installation resources.

If you have more questions or want tailored advice, feel free to contact our support team.

Customer Reviews & Case Studies

Many industrial users rely on Wilmall hollow rotary encoders for accurate motor shaft feedback and robust performance. Customers highlight the low runout and high concentricity that help improve machine precision and reduce downtime.

In real-world applications, our hollow shaft rotary encoders have excelled in harsh environments like packaging lines and robotic arms, where space-saving through-bore design and reliable feedback are critical. For example, a major conveyor system manufacturer reported smoother operation and easier installation thanks to our clamping ring encoder with torque arm mounting.

These success stories reflect Wilmall’s commitment to durable, high-quality hollow rotary encoders that meet the demands of diverse industries, from CNC machining to heavy industrial drives. If you want proven performance under tough conditions, Wilmall encoders are a trusted choice.

Related Searches & Quick Links

Looking for more on hollow shaft encoder solutions? Explore terms like through-bore rotary encoder, large bore encodery incremental hollow shaft encoder to find the perfect match for your application. For tailored assistance, use our contact form or click the Request Quote button to get a custom proposal fast.

Need compatible components? Check out Wilmall’s reliable aviation connectors designed for harsh environments to complement your hollow rotary encoder setup, ensuring secure and robust electrical connections.