The GLS45C Incremental Rotary Encoder delivers accurate and stable position and speed feedback for a wide range of industrial automation applications. Engineered for durability and precision, this encoder supports various output signals and features robust mechanical construction to withstand harsh operating environments, making it a reliable choice for advanced motion control systems.

Caractéristiques principales :

High-resolution incremental output with stable pulse signals

Compact and rugged design for industrial use

Multiple output options including TTL and open collector

Easy installation with standardized mounting flange and shaft coupling

Durable bearings and sealed design for longevity

Wide voltage supply range adaptable to different systems

Avantages du produit :

Ensures precise rotational feedback for enhanced control accuracy

Robust construction minimizes downtime and maintenance costs

Versatile compatibility with diverse industrial control systems

Improves machine performance in automated production lines

Enables flexible installation in confined spaces

Modèle de produit et signification

| G | L | S | 45 | C | 1000 | C | 3 | 2M | |||

| Catégorie de produit | Type of produit | Form of main shaft | Contour de la produit | Outlet and sealing form | Résolution | Formulaire de sortie | Output signal | Câble | |||

| G:incrémental type | L:photoelec- tricité | S:arbre plein | 45:φ45mm | C:rear outlet | 10,20,50,60,100,200,360, 400,500,600,800, 1000,1024,1200,2000,2048,2500, 3000,3600,4096 | C: open collector output F: complementary output L:5V drive output | 1:phase A signal 2:signal de phase AB 3:phase ABZ signal 4:phase ABA/B/ signal 6:phase ABZA/B/Z/ signal | Défaut 2m ligne, pour non 2m, labeling is suffisant | |||

Tableau de câblage

| Couleur de la ligne | Signal de sortie C/F | – | Couleur de la ligne | Signal de sortie |

| rouge | VCC | rouge | VCC | |

| noir | GND | |||

| noir | GND | |||

| vert | Une phase | |||

| vert | Une phase | blanc | Phase B | |

| jaune | Phase Z | |||

| blanc | Phase B | |||

| pink | Aphase | |||

| jaune | Phase Z | bleu | Bphase | |

| orange | Phase Z | |||

| bouclier | F -G | |||

| bouclier | F -G |

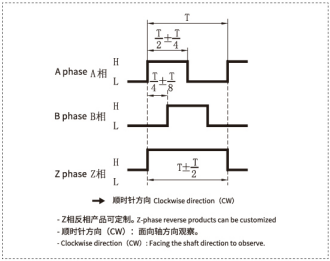

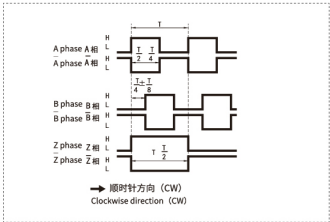

Différence de phase de la sortie

complementary output/NPN collector open circuit output

long line drive output

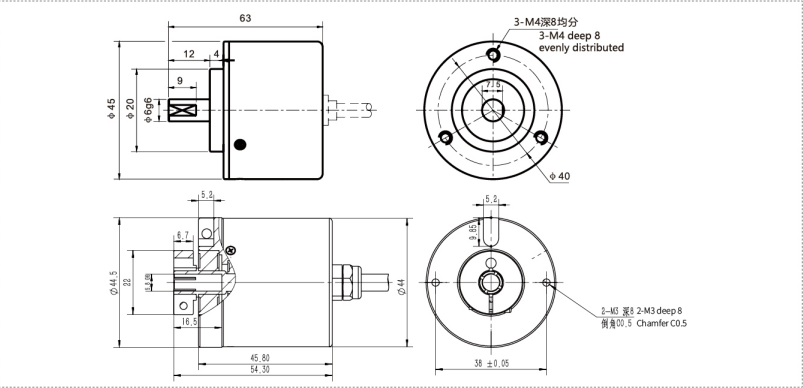

Dessins mécaniques (mm)

Installation and Maintenance Steps:

Mount the GLS45C encoder securely on the motor or machine shaft using the appropriate coupling.

Align the encoder shaft accurately with the drive shaft to prevent mechanical stress.

Connect the wiring according to the detailed wiring diagram, ensuring proper power supply and signal configuration.

Test the encoder output signals to verify correct operation with the control system.

Regularly inspect the encoder for dust, vibration effects, and mechanical wear.

Perform routine cleaning and lubrication if required, following the manufacturer’s guidelines.

Applications détaillées du produit :

Industrial automation and manufacturing lines requiring precise motion control

CNC machinery for real-time position feedback and speed regulation

Robotics where accurate shaft position detection is critical for operation

Conveyors and material handling systems to monitor speed and flow

Printing and packaging machines for synchronization and process control

Elevator systems to ensure smooth and safe shaft rotation monitoring

Wind turbine and renewable energy systems for blade position measurement

Medical devices where precision and reliability are essential

Demander un devis maintenant

Notre équipe vous répondra dans les 24 heures.