Le codeur rotatif incrémental GOS38E offre une précision et une durabilité exceptionnelles pour les applications d'automatisation industrielle et de contrôle des mouvements. Conçu avec un boîtier robuste conforme à la norme IP67, ce codeur excelle dans les environnements difficiles avec une forte résistance à la poussière et à l'eau. Il offre plusieurs résolutions d'impulsions et une sortie de signal push-pull fiable, ce qui permet d'obtenir un retour stable et précis de la position et de la vitesse. Idéal pour les moteurs, les systèmes de convoyage, la robotique et les machines d'emballage, le GOS38E s'intègre parfaitement grâce à son diamètre compact de 38 mm et à ses options de montage polyvalentes.

Caractéristiques principales :

Encodeur incrémental avec options de haute résolution (jusqu'à 5000 P/R) pour une détection fine des mouvements

La protection IP67 garantit une résistance supérieure à la poussière et à la pénétration de l'eau.

Le boîtier compact de 38 mm de diamètre s'adapte aux espaces mécaniques restreints

Large gamme de tensions d'alimentation de 5V à 24V DC pour une compatibilité flexible

Les signaux de sortie push-pull permettent une résistance robuste aux interférences électromagnétiques

Réponse à haute fréquence pour des mesures précises de la vitesse et de la position

Variantes d'arbre plein et d'arbre creux disponibles

Conception robuste adaptée aux environnements industriels

Large gamme de températures de fonctionnement couvrant les conditions industrielles typiques

Avantages du produit :

Des signaux incrémentaux fiables et de haute précision améliorent la précision de la commande de la machine

Le boîtier robuste IP67 prolonge la durée de vie du produit dans les applications difficiles

La taille compacte permet une installation dans des espaces restreints.

Formats de sortie flexibles et résolutions multiples pour une configuration personnalisée

Intégration aisée avec divers systèmes d'automatisation et de contrôle des moteurs

La construction durable réduit les temps d'arrêt et les coûts d'entretien

Modèle de produit et signification

| G | 0 | S | 38 | E | 600 | F | 3 | 2M | ||||

| Catégorie de produit | Type de produit | Forme de arbre principal | Contour de la produit | Taille de l'appareil principal arbre, trou d'arbre | Sortie et formulaire de scellement | Résolution | Formulaire de sortie | Signal de sortie | Câble | |||

| G:incrémental type | O:megneto- électricité | S:arbre plein | 38:φ38mm | □:φ6mm | E:sortie latérale en métal | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,5000 | C:sortie à collecteur ouvert F:sortie complémentaire T :sortie push pull L:Sortie d'entraînement 5V A:Sortie d'entraînement 24V | 1:phase Asignal 2:signal de phase AB 3:phase signal ABZ 4 : phase ABA/B/ signal 6:phase ABZA/B/Z/ signal | Défaut 2m ligne, pour les non 2m, il suffit d'étiqueter | |||

Tableau de câblage

Couleur de la ligne | Signal de sortie C/F | – | Couleur de la ligne | Signal de sortie L/A |

| rouge | VCC | rouge | VCC | |

| noir | GND | |||

| noir | GND | |||

| vert | Une phase | |||

| vert | Une phase | blanc | Phase B | |

| jaune | Phase Z | |||

| blanc | Phase B | |||

| brun | Aphase | |||

| jaune | Phase Z | gris | Bphase | |

| orange | Phase Z | |||

| bouclier | F -G | |||

| bouclier | F -G |

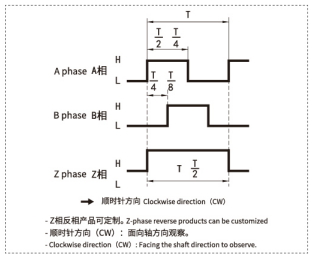

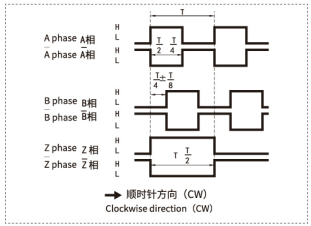

Différence de phase de la sortie

sortie/collecteur NPN sortie circuit ouvert

long line drive output

Dessins mécaniques (mm)

Installation et maintenance :

Assurez-vous que la surface de montage est propre et exempte de débris avant de procéder à l'installation.

Alignez soigneusement l'arbre du codeur avec l'arbre entraîné pour éviter tout désalignement. Utilisez des accouplements flexibles si nécessaire pour réduire les contraintes mécaniques.

Fixer l'encodeur avec le matériel de montage fourni pour minimiser les vibrations.

Brancher l'alimentation électrique dans la plage 5-24V DC, en respectant la polarité et les bonnes pratiques de mise à la terre.

Connecter les signaux de sortie (canaux A, B, Z) à l'entrée du système de contrôle tout en protégeant les câbles du bruit électromagnétique.

L'entretien de routine comprend un nettoyage périodique pour éliminer l'accumulation de poussière et un contrôle de l'étanchéité des connexions électriques.

Évitez d'exposer le codeur à des chocs extrêmes ou à des contaminants chimiques.

Remplacer rapidement le codeur en cas d'instabilité du signal ou de dommages mécaniques.

Scénarios d'application :

Moteurs industriels pour un retour d'information précis sur la position de rotation

Systèmes de convoyage nécessitant une surveillance et un contrôle de la vitesse

Robotique pour une détection précise des mouvements des articulations et des axes

Machines d'emballage pour les opérations de synchronisation et de comptage

Contrôle de la vitesse de rotation et de la position des rouleaux sur les machines d'impression

Lignes d'assemblage automatisées pour un contrôle précis des mouvements

Demander un devis maintenant

Notre équipe vous répondra dans les 24 heures.