Le codeur rotatif GOS5008B est conçu pour fournir un retour d'information robuste et fiable sur la rotation, garantissant des performances constantes dans des environnements exigeants. Doté d'une conception robuste et d'options de sortie polyvalentes, ce codeur offre des signaux de vitesse et de position précis qui sont essentiels pour diverses applications d'automatisation et de machinerie. Conçu pour une utilisation intensive, il permet d'améliorer la surveillance et le contrôle des mouvements avec un minimum de maintenance.

Caractéristiques principales :

Sortie incrémentale haute résolution fournissant des signaux d'impulsion stables et cohérents

Boîtier robuste, étanche à la poussière et aux vibrations pour une longue durée de vie

Prise en charge de plusieurs formats de sortie, y compris les signaux TTL et à collecteur ouvert

Fixation par bride et accouplement d'arbre standard pour une installation facile et sûre

Boîtier étanche et roulements de qualité supérieure pour prolonger la durée de vie de l'appareil

Large gamme de tensions pour une intégration transparente avec différentes sources d'alimentation

Avantages du produit :

Fournit un retour d'information fiable et régulier pour optimiser la précision des mouvements de la machine

La construction robuste minimise les temps d'arrêt dus à l'usure et aux conditions difficiles.

Les options flexibles de sortie et de montage simplifient l'intégration du système

Améliore les performances de la machine en garantissant des données de mouvement précises et en temps réel

La taille compacte s'adapte facilement aux espaces restreints sans compromettre les performances

Modèle de produit et signification

| G | 0 | s | 50 | 06 | B | 1000 | c | 3 | 2M | |||

| Catégorie de produit | Type de produit | Forme de l'arbre principal | Contour de la produit | Taille de l'arbre principal, trou de l'arbre

| Sortie et formulaire de scellement | Résolution | Formulaire de sortie | Signal de sortie | Câble | |||

| G:type incrémental | 0:megneto électricité L:photoelec- tricité | S:arbre plein | 50:φ50mm | □:φ8mm 06:φ6mm | E:sortie latérale en métal D : sortie arrière en métal | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:sortie à collecteur ouvert F:sortie complémentaire T:sortie push pull L:Sortie d'entraînement 5V A:Sortie d'entraînement 24V | 1: phase Asignal 2: signal de phase AB 3:phase signal ABZ 4:phase ABA/B/ signal 5:phase ABZA/B/Z/ signal | Défaut 2m lne,Pour non 2m, le labeing est suffisant |

Tableau de câblage

| Couleur de la ligne | Signal de sortie C/F/T | Couleur de la ligne | Signal de sortie L/A | |

| rouge | VCC | rouge | VCC | |

| noir | GND | |||

| noir | GND | |||

| vert | Une phase | |||

| vert | Une phase | blanc | Phase B | |

| jaune | Phase Z | |||

| blanc | Phase B | |||

| brun | Une phase | |||

| jaune | Phase Z | gris | Bphase | |

| orange | Phase Z | |||

| bouclier | F -G | |||

| bouclier | F -G |

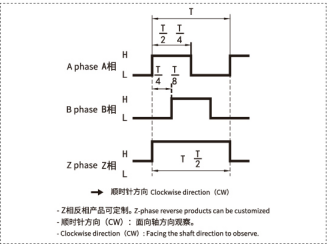

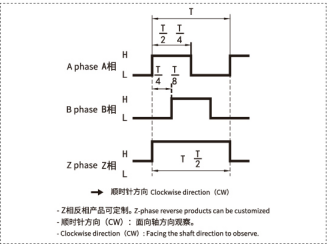

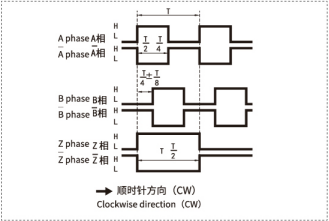

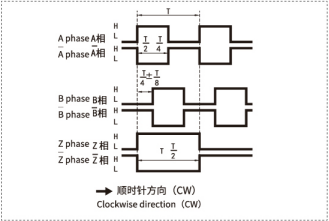

Différence de phase de la sortie

sortie complémentaire/push pull sortie/collecteur NPN sortie circuit ouvert

sortie de l'entraînement de la palangre

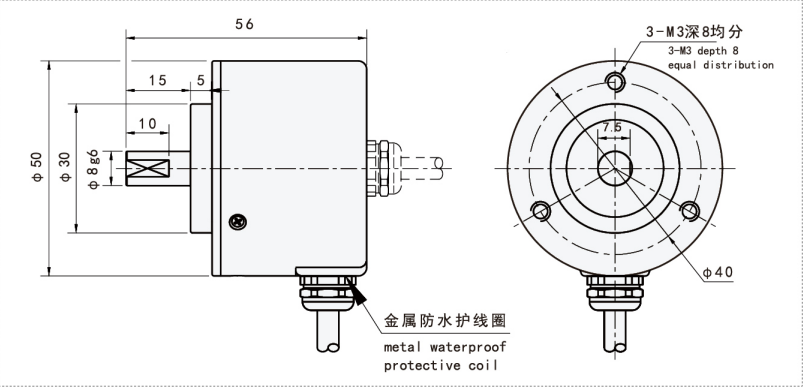

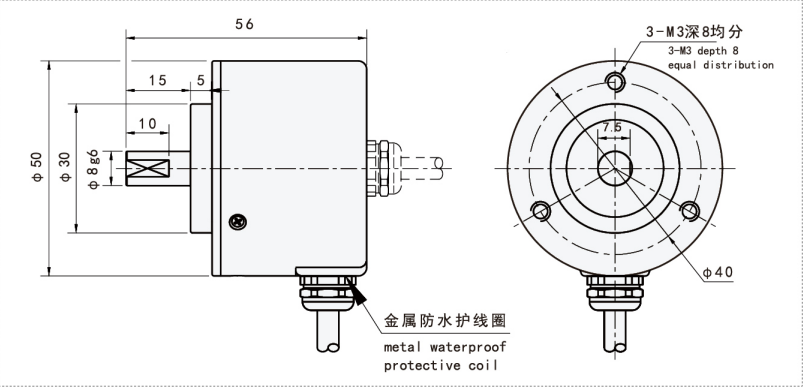

Dessins mécaniques (mm)

Installation et entretien :

Monter solidement le codeur GOS5008B sur l'arbre de l'équipement à l'aide de l'accouplement ou de l'adaptateur fourni.

Assurer un alignement précis de l'arbre pour éviter l'usure mécanique et la distorsion du signal.

Connecter le câblage conformément au schéma fourni, en vérifiant que toutes les connexions sont correctes.

Testez les signaux de sortie avec votre système de contrôle ou de surveillance avant la mise en service complète.

Nettoyez périodiquement le boîtier du codeur pour éliminer l'accumulation de poussière et de débris.

Inspecter régulièrement le matériel de montage, les raccords mécaniques et les connecteurs électriques ; lubrifier les composants selon les recommandations.

Applications détaillées du produit :

Idéal pour les environnements robustes et sensibles, le codeur rotatif GOS5008B est parfait pour :

Systèmes de manutention et de convoyage nécessitant un contrôle précis de la vitesse et de la position

Bras robotiques et machines automatisées exigeant un retour d'information constant sur les mouvements

Équipement d'emballage et d'impression pour une synchronisation précise et un contrôle de la qualité

Systèmes d'ascenseurs et d'escaliers roulants pour assurer une rotation fluide et sûre de la gaine

Systèmes d'énergie renouvelable tels que les éoliennes pour le positionnement des pales et la détection de la vitesse.

Machines agricoles et de construction fonctionnant dans des conditions extérieures difficiles

Dispositifs médicaux et instruments de laboratoire nécessitant des données de rotation fiables

Le GOS5008B fait partie d'une catégorie plus large de codeurs rotatifs incrémentaux dont la technologie a considérablement évolué, en se concentrant sur l'amélioration de la durabilité et de l'intégrité du signal dans des environnements difficiles. Ces codeurs jouent un rôle crucial dans l'automatisation intelligente en fournissant des données de rotation en temps réel qui ont un impact direct sur la précision et l'efficacité du système. Il est essentiel de comprendre les pratiques d'installation et les routines d'entretien appropriées pour maximiser les performances et la longévité des codeurs. En outre, les innovations en matière de matériaux pour codeurs et de technologies d'étanchéité continuent de repousser les limites de leur application, ouvrant la voie à leur utilisation dans des conditions extrêmes telles que la production d'énergie en mer et les machines lourdes dans les opérations minières.

Demander un devis maintenant

Notre équipe vous répondra dans les 24 heures.