오버헤드 크레인 원격 제어란 무엇인가요?

대형 산업용 크레인을 안전한 거리에서 정밀하고 쉽게 제어할 수 있다고 상상해 보세요. 바로 오버헤드 크레인 원격 제어 기술이 제공하는 기능입니다. 이 기술은 공장, 건설 현장, 창고에서 무거운 하중을 처리하는 방식을 혁신하여 작업을 더 안전하고, 더 빠르고, 더 효율적으로 만듭니다. 건설 현장에서 철골 빔을 들어 올리든 [...] [...]

자세히 보기

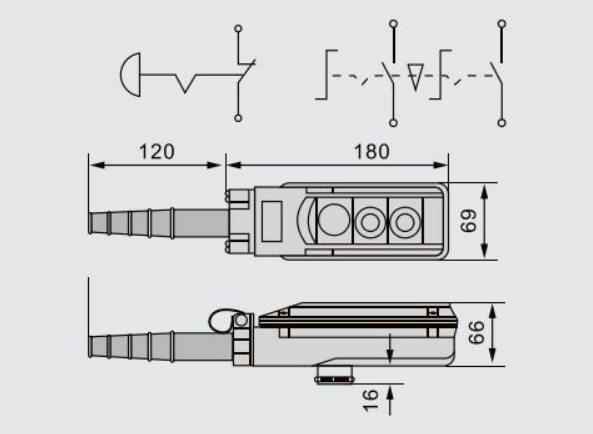

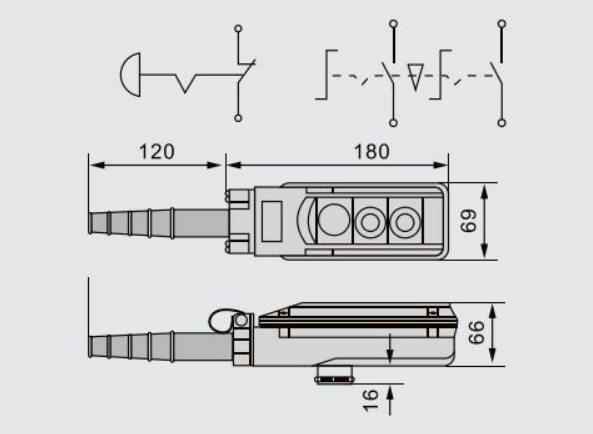

이란 무엇인가요? 펜던트 제어 스테이션? A simple handheld interface that gives operators direct, safe control over large industrial equipment from a distance. Think of it as the operator’s extended hand, letting you start, stop, lift, or orient a crane or conveyor without stepping close to moving parts. It combines ergonomic design with robust electrical safety features so you can work efficiently while protecting people and machinery.

In a world where uptime matters, a Pendant Control Station is a practical investment for any facility handling lifting, material handling, or automated processes. If you’re evaluating options for your plant, this guide explains what Pendant Control Station is, why it matters, and how to choose the right model for your needs—and how to place an order or request a quote with ease. Ready to explore? Let’s dive in.

A COB-61C Pendant Control Station is a handheld control unit that houses a group of switches, pushbuttons, or joysticks. It signals a machine’s controller—such as a PLC or relay network—to perform actions like start, stop, reverse, lift, or lower. It often sits on a flexible cord that connects to the equipment, so the operator can stay outside of the machine’s immediate danger zone while controlling movement.

These stations are widely used with cranes, hoists, conveyors, pumps, and other industrial machinery, where precision and safety are paramount. The design emphasizes reliability, ease of maintenance, and clear visual cues (LED indicators, color-coding) that help operators verify mode and status at a glance. If you’re ordering for a facility that handles heavy loads or automated lines, a Pendant Control Station should be a central consideration.

The operator activates a control element (button or joystick).

The signal travels through a connection to the system’s controller.

The controller interprets the input and drives the appropriate actuator (motor, valve, or relay).

Safety interlocks and emergency stop cut power when needed.

Status indicators on the pendant provide feedback to the operator.

| 단계 | Action | Outcome |

|---|---|---|

| 1 | Button pressed | Signal is sent to controller |

| 2 | Controller interprets | Executes commanded action |

| 3 | Actuator responds | Machinery moves accordingly |

| 4 | Safety interlock checks | System stays safe, or stops on fault |

| 5 | Operator sees status | LED or display confirms state |

Ergonomics and ease of use reduce operator fatigue and training time.

Remote operation keeps workers out of hazardous zones.

Built-in safety features such as emergency stop (E-stop) enhance risk management.

Customizable layouts (button count, switch types, joystick interfaces) support diverse equipment.

Durable enclosures protect against dust, moisture, and mechanical shock.

Compatibility with cranes, hoists, conveyors, and bespoke automation systems.

| 혜택 | Why it matters for your plant | Typical scenarios |

|---|---|---|

| Ergonomic design | Improves comfort and reduces errors | Long shifts, repetitive controls |

| Remote operation | Improves safety around moving equipment | Crane operation, lifting tasks |

| 안전 기능 | Minimizes risk and compliance concerns | Emergency stops, guarded operations |

| Customizable layouts | Fits exact control needs | Different job sites with unique controls |

| Rugged enclosure | Withstands harsh industrial environments | Dusty workshops, damp facilities |

| Equipment compatibility | Works with existing automation | Integration with PLCs and VFDs |

Pendant Control Station configurations vary by contact arrangement, speed, and features. The most common distinctions are:

Single vs. double contact types

Mechanical versus electronic interlocks

Presence of emergency stop, reset, and indication lights

Waterproof or dustproof rating (IP/NEMA)

Corded versus wireless variants (for certain environments)

Long-tail ideas to weave into sections:

소니 엔지니어가 고객의 정확한 업무 주기와 환경에 맞게 펜던트 제어 스테이션 솔루션을 맞춤 제작할 수 있습니다. 레이아웃 목업, 커스터마이징 타임라인, 의무 없는 비용 견적을 제공합니다.

Determine the workload: lifting capacity, motor type (AC/DC), speed control requirements

Assess environmental conditions: dust, moisture, temperature, washdown needs

Check compatibility: PLC inputs, safety circuits, radio interference

Plan for maintenance: availability of spare parts, modular components, service life

Evaluate certifications: compliance with local safety standards and industry norms

| 요인 | Questions to answer | Recommended preference |

|---|---|---|

| 환경 | Dust, water exposure, cleaning methods | IP65 or higher, sealed enclosure |

| Control needs | Number of operations, speed control | Match button count; include speed/joystick if needed |

| 안전 | E-stop, safety interlocks | Always include E-stop and reset features |

| 배선 | System voltage, PLC compatibility | Ensure voltage and signal levels align with PLC |

| 유지 관리 | Spare parts availability | Choose brands with local support |

A Pendant Control Station typically includes:

When designing or selecting a pendant, it’s vital to ensure the enclosure offers sufficient ingress protection for your environment, and that the control elements are rated for the voltage and current of your system. A well-designed pendant also includes clear labeling and a layout that minimizes operator confusion during high-stress tasks. A good vendor will offer variants with modular components so you can tailor the pendant to a specific equipment stack or workflow.

| 구성 요소 | 역할 | 중요한 이유 |

|---|---|---|

| 인클로저 | Protects internals from dust and water | Prolongs life, reduces maintenance |

| Pushbuttons | Primary on/off and function controls | Intuitive operation, quick training |

| Emergency stop | Immediate power cut in emergencies | Critical safety feature |

| Indicator lights | Visual status cues | Quick situational awareness |

| Joystick (optional) | Directional/velocity control | Precision in crane or conveyor movement |

| Cable assembly | Connects pendant to equipment | Reliability of signals and ease of routing |

Pendant Control Station types can be categorized by application and configuration:

| 애플리케이션 | Why it fits | Key features to look for |

|---|---|---|

| Cranes/Hoists | Direct crane and hook control | Many buttons, dead-man tolerance, E-stop |

| Conveyors | Start/stop with optional speed control | Quiet operation, robust wiring |

| Process lines | Sequencing and safety control | Clear status indicators, modularity |

| Custom automation | Unique control sequences | Custom labeling, programmable inputs |

Safety is a core benefit of Pendant Control Station use. Operators can stay at a safe distance from moving machinery while still controlling it directly. The most effective pendants include:

In practice, this translates to fewer near-misses, faster response times, and easier training. When a new operator joins, a pendant-based workflow is typically quicker to learn compared with fixed control panels that require a fixed position in a control room.

| Practice | 혜택 | 예 |

|---|---|---|

| Cable routing | Reduces wear and trip hazards | Use cable trays and strain relief |

| Ergonomic placement | Reduces fatigue | Place at comfortable height and angle |

| Safety interlock testing | Confirms protection | Simulate fault conditions |

| Labeling | Simpler maintenance | Clear button legends and color codes |

| Documentation | Faster maintenance | Keep an up-to-date wiring diagram |

| Task | Frequency | Indicator of good health |

|---|---|---|

| Visual inspection of buttons and housing | Weekly | No cracks, no moisture intrusion |

| Function test of each control | Monthly | All functions respond correctly |

| Safety interlock check | Quarterly | Interlock engages reliably |

| Seals and gaskets check | Semi-annually | Intact seals, no leaks |

| Cable and connector inspection | Annually | No frayed wires, secure connections |

펜던트 제어 스테이션 is more than a handheld gadget. It’s a practical, safety-forward way to manage heavy equipment from a safe distance. By choosing the right configuration, you ensure reliable operation, faster response times, and better overall plant safety. Whether you operate cranes, conveyors, or automated lines, a well-chosen 펜던트 스테이션 can become a core component of your control ecosystem. If you’d like to discuss options, request a tailored recommendation, or receive a quote, reach out today.

Heavy lifting, material handling, automation lines, and remote operation tasks across manufacturing and warehousing benefit most; cranes and hoists are classic examples.

Start with your primary operations. If the job involves multiple steps, include dedicated buttons or a joystick for essential commands; add optional indicators for status.

Yes, for environments where cables hinder movement or safety, wireless pendants with robust pairing and interference protection are common.

Absolutely. Many suppliers offer modular button layouts, color coding, and programmable features to fit specific tasks.

Regular inspection of buttons, seals, and connectors; replacement of worn parts; and verification of safety interlocks during periodic safety checks.

애플리케이션 세부 정보(듀티 사이클, 주변 조건, PLC 인터페이스)를 공유하고 공식적인 공급업체 평가 체크리스트와 상위 옵션의 나란히 비교를 받아보세요.