Absolute Rotary Encoder High Resolution Types and Applications

Explore high-precision absolute rotary encoders with multi-turn tracking serial interfaces and durable design for reliable position feedback in automation.

자세히 보기

When you’re working with automation, robotics, or industrial control systems, you’ll often come across the term “encoder.”

But have you ever stopped to wonder what the encoder symbols means in technical diagrams?

Let’s break it down together—so the next time you see an encoder symbol, you’ll know exactly what you’re looking at and why it matters.

An encoder symbol is a standardized graphic used in electrical and automation schematics to represent an encoder component.

Just like a musical note tells a musician what to play, the encoder symbol tells engineers and technicians what’s happening in the circuit.

It’s a visual shorthand that helps everyone speak the same technical language, no matter where they’re from.

You might think every company draws these symbols their own way, but that would be chaos. T

hat’s why organizations like the International Electrotechnical Commission (IEC) created standards—specifically IEC 60617—to make sure encoder symbols look and mean the same thing everywhere.

In the United States, you’ll also see standards from ANSI and IEEE, but IEC 60617 is the global go-to.

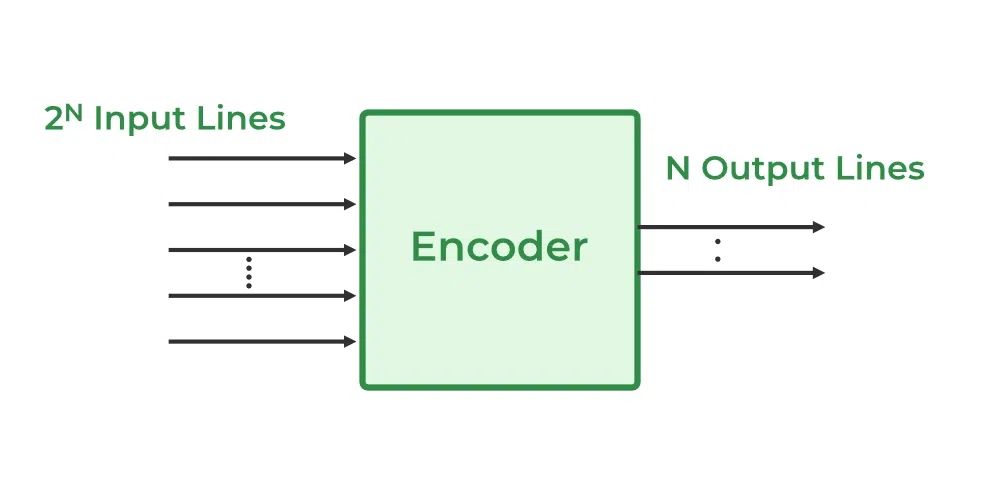

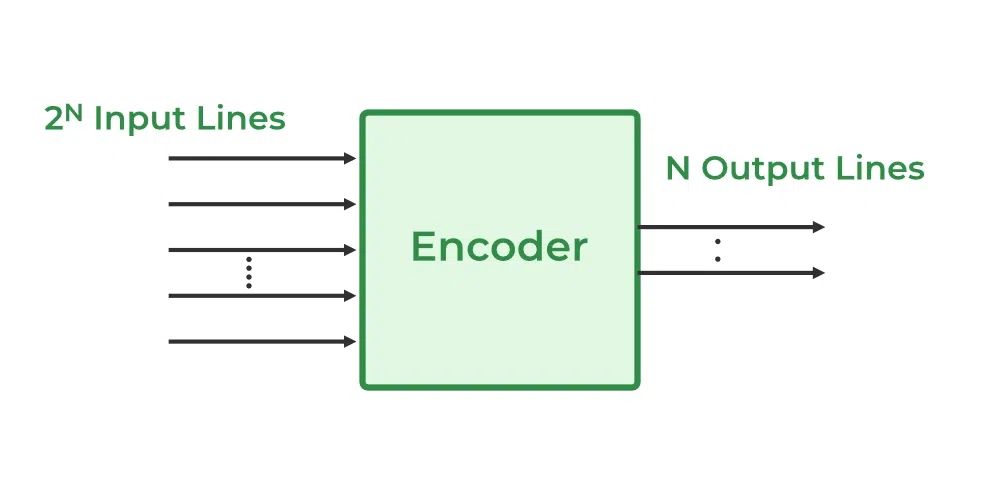

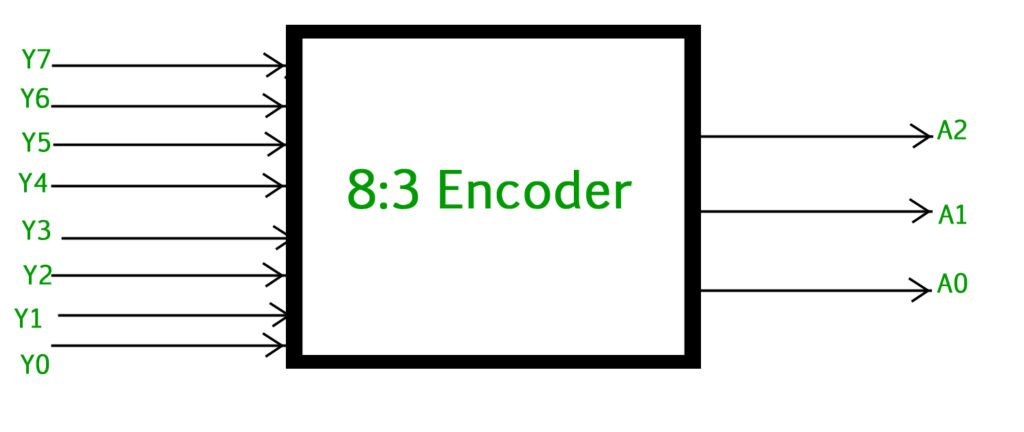

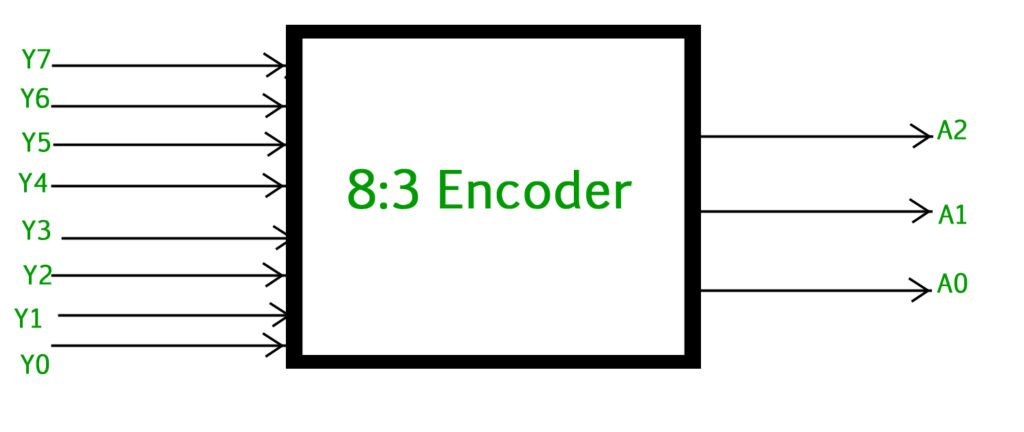

According to these standards, an encoder symbol usually appears as a rectangle (representing the device) with input and output terminals.

For rotary encoders, you’ll often see a small circle or arc attached, showing the rotating shaft.

Sometimes, the symbol includes arrows for direction or labels like “ENCODER” to make things crystal clear.

Not all encoders are created equal, and neither are their symbols. Here’s what you’ll typically find:

You’ll also spot variations for incremental and absolute encoders. Incremental encoder symbols may include extra lines for reference (like the Z-channel), while absolute encoders might feature additional labels or a unique outline.

When you see an encoder symbol on a schematic, pay attention to:

If you’re drawing your own diagrams, stick to the standards. Use clear rectangles, mark all terminals, and add any necessary labels. This keeps your documentation clear and professional.

Let’s get practical. Imagine you’re reading a control panel diagram for a conveyor system. You’ll see the encoder symbol right next to the motor, with output lines leading to a PLC. In a robot arm schematic, the encoder symbol sits at each joint, showing how the system tracks position and movement.

Case in point: If you’re troubleshooting why a conveyor isn’t stopping where it should, tracing the encoder symbols in the wiring diagram helps you quickly find the right connections and signals.

Encoders aren’t the only devices with special symbols.

You’ll also run into decoders, sensors, and transducers. While they might look similar—a rectangle here, a triangle there—each has its own unique features.

For example, a decoder symbol usually has more outputs than inputs, while a sensor symbols might include a wave or arrow. Always double-check the labels and context to avoid confusion.

Understanding the encoder symbols isn’t just about reading diagrams—it’s about speaking the universal language of engineering.

Whether you’re designing a new system, troubleshooting an old one, or just trying to make sense of a complex schematic, knowing what the encoder symbol means will save you time and headaches.

So next time you spot that little rectangle with a circle or arrow, you’ll know: that’s the heartbeat of precision motion in your automation system.

Standard symbols keep diagrams clear and consistent, making global collaboration possible.

최신 기호 정의는 IEC 60617 또는 업계에서 선호하는 표준을 확인하세요.

인크리멘탈 인코더에는 참조 채널이 표시되고 앱솔루트 인코더에는 고유한 표시가 있을 수 있으므로 라벨이나 추가 줄이 있는지 확인합니다.