GLS50H 로터리 엔코더는 까다로운 기계 및 자동화 애플리케이션을 위해 설계된 신뢰할 수 있고 일관된 회전 피드백을 제공합니다. 견고한 구조와 다양한 출력 옵션으로 설계된 이 엔코더는 안정적인 속도 및 위치 신호를 제공하여 원활한 모션 추적과 시스템 효율성을 지원합니다. 내구성이 뛰어난 설계와 간편한 설치로 다양한 산업 환경에 적합합니다.

주요 기능:

안정적인 펄스 신호를 생성하는 고해상도 증분 출력

먼지, 습기, 진동으로부터 보호하는 견고한 밀폐형 인클로저

유연한 통합을 위한 TTL 및 오픈 컬렉터 출력 포맷 지원

간편한 설치를 위한 표준 플랜지 마운팅 및 샤프트 커플링

프리미엄 베어링으로 작동 수명 연장 보장

넓은 전압 입력 범위로 다양한 전원 공급 장치 요구 사항에 맞게 조정 가능

제품 이점:

안정적이고 지속적인 모션 피드백을 제공하여 운영 일관성 향상

열악한 환경에서도 다운타임을 최소화하는 견고한 설계

유연한 출력 및 마운팅 옵션으로 시스템 통합 간소화

컴팩트한 크기로 공간 제약이 있는 애플리케이션에 설치 가능

낮은 유지보수 요구 사항으로 전체 시스템 가동 시간 향상

제품 모델 및 의미

| G | L | S | 50 | □ | H | 1000 | T | 3 | 2M | ||||

| 카테고리 제품 | 제품 유형 | 형태 메인 샤프트 | 컨투어 제품 | 메인 크기 샤프트, 샤프트 구멍 | 아울렛 및 씰링 양식 | 해상도 | 출력 양식 | 출력 신호 | 케이블 | ||||

| G:증분 유형 | L:photoelec- 트라이시티 | S:솔리드 샤프트 | 50:φ50mm | □:Φ8mm | H:후면 배출구 플라스틱 | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:오픈 컬렉터 출력 T:푸시 풀 출력 L:5V 5V 드라이브 출력 A:24V 드라이브 출력 | 1:위상 A 신호 2:위상 AB 신호 3:위상 ABZ 신호 4:위상 ABA/B/ 신호 6:위상 ABZA/B/Z/ 신호 | 기본값 2m 라인, 2m가 아닌 경우, 라벨링으로 충분합니다. | ||||

배선 테이블

| 선 색상 | C/F/T 출력 신호 | 선 색상 | L/A 출력 신호 | |

| 갈색 | VCC | 갈색 | VCC | |

| 파란색 | GND | |||

| 파란색 | GND | |||

| 검은색 | 단계 | |||

| balck | 단계 | 흰색 | B 단계 | |

| 범위 | Z 단계 | |||

| 흰색 | B 단계 | |||

| 빨간색 | 단계 | |||

| 오렌지 | Z 단계 | 회색 | B단계 | |

| 노란색 | Z 단계 | |||

| 방패 | F -G | |||

| 방패 | F -G |

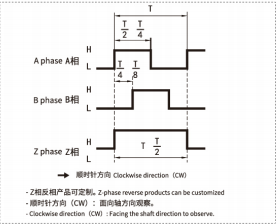

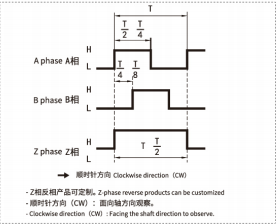

출력 위상차

보완적 출력/NPN 콜렉터 개방 회로 출력

롱라인 드라이브 출력

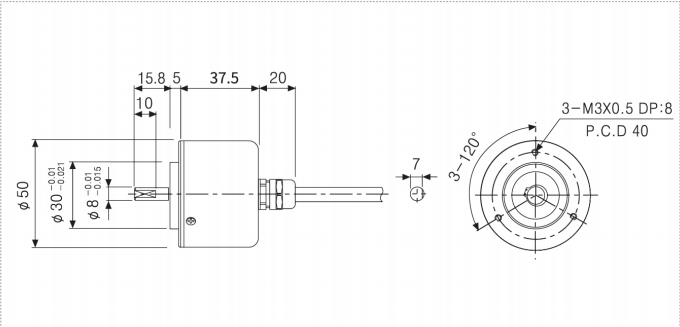

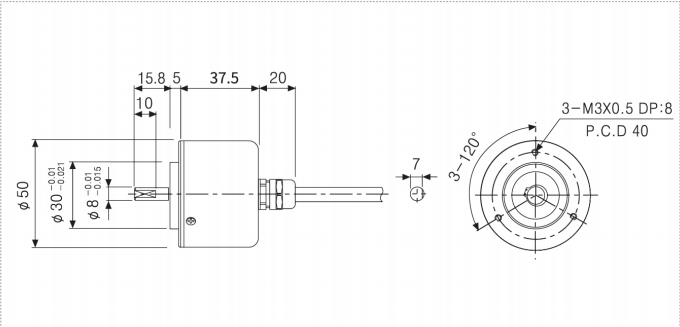

기계 도면(mm)

설치 및 유지 관리:

제공된 커플링 또는 어댑터를 사용하여 GLS50H 인코더를 샤프트에 단단히 장착합니다.

기계적 스트레스와 부정확한 판독값을 방지하기 위해 샤프트가 올바르게 정렬되었는지 확인하세요.

제공된 회로도에 따라 배선을 정확하게 연결하여 전원과 신호가 올바른지 확인하세요.

전체 배포 전에 제어 시스템으로 출력 신호 테스트를 수행하세요.

인코더 본체를 정기적으로 청소하여 먼지와 이물질이 쌓이는 것을 방지합니다.

하드웨어와 연결부를 주기적으로 점검하고, 권장되는 대로 베어링에 윤활유를 바릅니다.

자세한 제품 애플리케이션:

GLS50H 인코더는 다음과 같은 다양한 애플리케이션에 적합합니다:

속도와 위치를 모니터링하는 컨베이어 및 자재 취급 시스템

안정적인 동작 신호가 필요한 로보틱스 및 자동화 장비

공정 동기화를 위한 포장 및 인쇄 기계

원활하고 안전한 샤프트 모니터링을 위한 엘리베이터, 에스컬레이터, 리프트

블레이드 위치 피드백을 위한 풍력 터빈과 같은 재생 에너지 시스템

까다로운 환경의 농업 기계 및 중장비

신뢰할 수 있는 회전 감지가 필요한 의료 및 실험실 장비

GLS50H와 같은 로터리 엔코더는 자동화 및 기계 시스템 전반에서 모션 피드백의 신뢰성을 향상시키는 데 중요한 구성 요소입니다. 엔코더 기술의 발전은 까다로운 조건에서 지속적인 작동을 보장하기 위해 환경 저항과 신호 무결성을 개선하는 데 중점을 두고 있습니다. 정렬 및 배선 정확도를 포함한 적절한 설치 기술은 엔코더의 수명과 성능에 큰 영향을 미칩니다. 또한 엔코더를 최신 디지털 제어 플랫폼과 통합하면 예측 유지보수 및 시스템 진단이 가능해져 보다 스마트하고 효율적인 기계 운영을 위한 기반을 마련할 수 있습니다.

지금 견적 요청하기

저희 팀이 24시간 이내에 연락을 드릴 것입니다.