Rotary Encoder Types Features Applications and Usage Tips

목차

What Is a Rotary Encoder and How Does It Work?

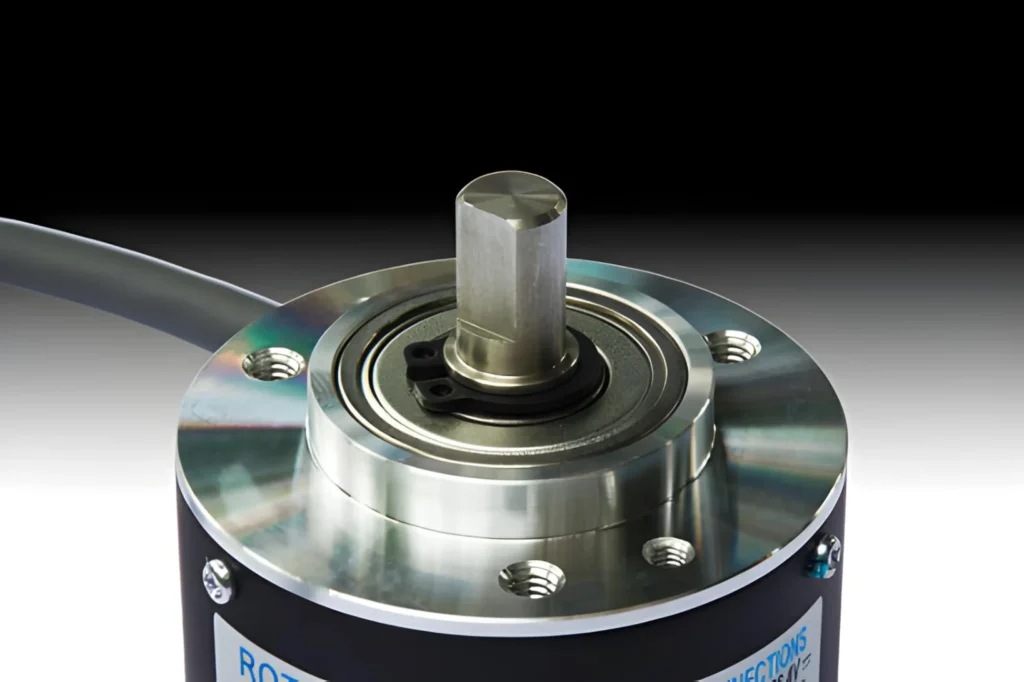

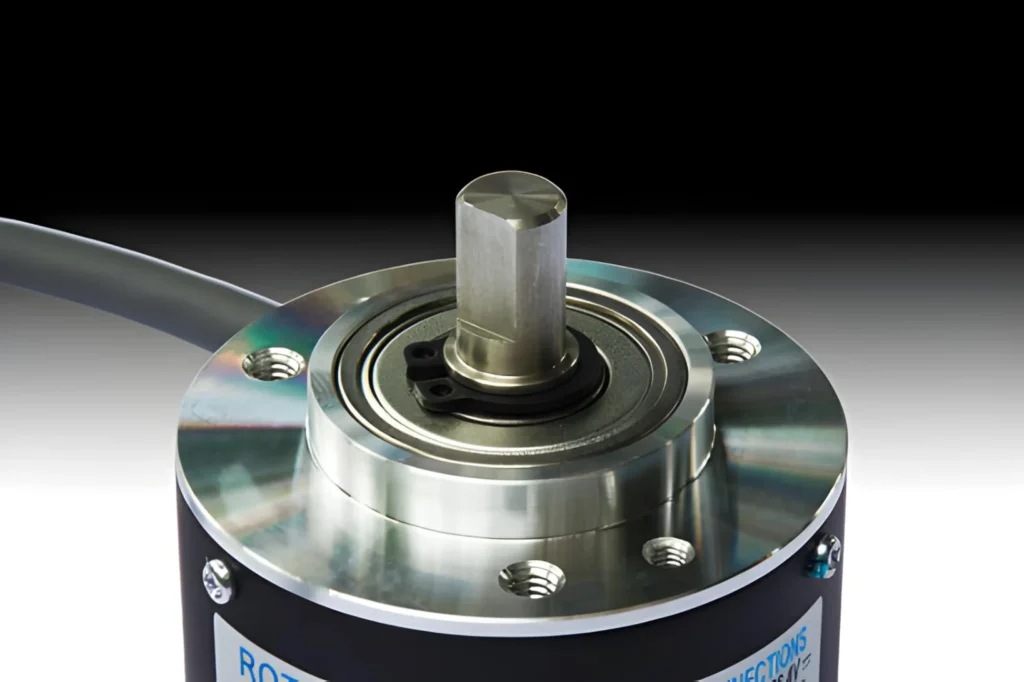

A rotary encoder is a sensor that converts rotational motion into digital electrical signals. It helps measure the position, speed, or direction of a rotating shaft, making it essential in robotics, industrial controls, and DIY projects.

Core Principle

At its heart, a rotary encoder translates the mechanical rotation of a shaft into a sequence of electrical pulses. These signals accurately represent the shaft’s angular position or movement.

Basic Components

- Shaft: The rotating part connected to the device you want to measure.

- Code Disk/Wheel: A patterned disk attached to the shaft that either blocks or reflects light or changes magnetic fields.

- 센서: Detect patterns on the disk. Common types include:

- 광학 센서—use light to read the disk’s markings and offer high accuracy.

- Magnetic sensors—detect changes in magnetic fields, ideal for dusty or harsh environments.

- Output Signals: Electrical pulses generated as the shaft rotates, representing position or movement.

Incremental vs. Absolute Encoders

- Incremental rotary encoders output a series of pulses indicating movement. They track relative position but lose exact position information if power is lost.

- Absolute rotary encoders provide a unique digital code for each shaft position, retaining the exact angle even after power cycles. Ideal for precise control.

Signal Output Explained

Most rotary encoders use quadrature signals, with two output channels called A and B:

- These channels produce square waves shifted in phase, enabling the detection of rotation direction (clockwise or counterclockwise).

- The number of pulses per full turn is called pulses per revolution (PPR) and determines resolution.

- By analyzing the phase difference between channels A and B, your system can track movement direction and speed.

Visual Breakdown of Pulse Generation

As the shaft rotates:

- Clockwise rotation: Channel A leads channel B.

- Counterclockwise rotation: Channel B leads channel A.

- Each pulse corresponds to a fixed angular step, making it simple to count and translate into meaningful position data.

This clear, stepwise digital output is why rotary encoders are preferred over analog devices like potentiometers in many applications.

Wilmall offers high-quality rotary encoders that combine reliable signal output with durable construction, ideal for both hobbyists and industrial users seeking precision and longevity.

Main Types of Rotary Encoders

Rotary encoders mainly come in two types: incremental rotary encoders 그리고 absolute rotary encoders, each with its own strengths.

Incremental Rotary Encoders

Incremental encoders are popular for being cost-effective 그리고 fast, making them easy to integrate into many projects. They output pulses as the shaft rotates, which your system counts to track movement. Common specs range from 12 to 1024 pulses per revolution (PPR), and many models include a push button feature. These encoders are widely used in applications where you only need relative position or speed information.

Absolute Rotary Encoders

Absolute encoders provide a unique output for every shaft position, so they retain position data even after a power loss. This makes them perfect for precise positioning tasks. There are two main types: single-turn for positions within one rotation, and multi-turn for tracking over multiple rotations. Both types prevent losing track of position, which is vital in industrial or robotic use.

Technology Breakdown

Optical Rotary Encoders: These use a light source and photodetectors to read a code disk, delivering high accuracy. Optical encoders are common in hobby projects and precision applications where detail matters.

Magnetic Rotary Encoders: Built to withstand harsher environments, magnetic encoders use magnetic fields and sensors instead of light, making them immune to dust and dirt. They’re reliable in industrial setups exposed to contamination.

Other Types: You’ll also find inductive 그리고 capacitive encoders, though they are less common. They offer unique sensing methods but generally serve niche applications.

For a robust solution suited for tough environments, check out Wilmall’s proximity switch shielded M12 sensors that complement magnetic encoder setups, ensuring durability and consistent performance in industrial use cases.

Explore options like the GOS5008A01 optical rotary encoder known for precision and reliability.

Rotary Encoder vs. Potentiometer: Which One Should You Use?

When choosing between a rotary encoder and a potentiometer, it’s important to understand their differences in function, durability, and typical applications. Here’s a quick comparison to help you decide:

| 기능 | 로터리 인코더 | Potentiometer |

|---|---|---|

| Rotation Range | Infinite turns (no stops) | Limited turns (usually < 300°) |

| 출력 유형 | Digital pulses (quadrature signals) | Analog voltage |

| 내구성 | No physical wear on sensing element | Wears out over time due to contact |

| 해상도 | High resolution (pulses per revolution) | Limited by mechanical precision |

| 비용 | Moderate to high, varies by type | Generally low cost |

When Rotary Encoders Win

Rotary encoders excel in applications needing unlimited rotation, precise position tracking, and robust digital output — especially with incremental rotary encoders that provide fine resolution without wear. They are perfect for motor feedback, volume controls with detents, or menu navigation on Arduino and Raspberry Pi projects.

When Potentiometers Still Make Sense

Potentiometers are ideal for simple, cost-sensitive controls where you don’t need endless rotation or digital readings. They are great for basic volume knobs, light dimmers, or analog input controls where smooth voltage variation matters more than exact position counts.

By understanding these key differences, you can choose the right tool for your project’s needs. For durable rotary encoder solutions that handle tough environments, also consider pairing them with high-quality connectors and cable glands, like the reliable aviation connector wiring for secure installations.

Key Applications and Real-World Use Cases

Rotary encoders are everywhere, from simple DIY projects to heavy-duty industrial machines. They convert rotary motion into clear electrical signals, making them invaluable for precise control and feedback.

Hobby and DIY Projects

For hobbyists and makers, rotary encoders are a staple when working with Arduino or Raspberry Pi. They’re perfect for navigating menus, controlling volume, or even guiding robot movement thanks to their reliable incremental signals and easy integration. Adding a rotary encoder with push button adds extra control without extra clutter—great for compact projects.

Industrial Applications

In industrial settings, rotary encoders provide critical motor feedback in CNC machines, conveyor belts, and robotic arms. Absolute rotary encoders help retain position info even if power is lost, ensuring precise and safe operation. Their durability and high resolution keep assembly lines running smoothly. For tough environments, magnetic rotary encoders shine by resisting dust and vibrations.

소비자 가전

You’ll find rotary encoders in audio equipment for volume knobs, automotive controls for dashboards, and medical devices requiring accurate positional feedback. Their digital output and long life make them ideal where reliability matters.

Wilmall’s range of rotary encoders stands out because of their robust build and consistent performance across all these applications. Whether you need a high-resolution optical rotary encoder for precision or a rugged magnetic option for harsh industrial conditions, Wilmall has you covered. Explore the full lineup of reliable rotary encoder products designed to meet real-world demands.

올바른 로터리 엔코더를 선택하는 방법

Picking the right rotary encoder means paying close attention to a few key specs and your project’s demands. Here’s a quick guide to help you decide:

| Spec | 고려해야 할 사항 |

|---|---|

| 해상도(PPR) | Higher pulses per revolution (PPR) = finer control for precise positioning. |

| 출력 유형 | TTL signals for direct digital use; open collector for flexible interfacing. |

| Voltage | Match the encoder voltage with your system, commonly 5V or 12V. |

| Shaft Size | Ensure shaft diameter fits your mechanical setup (e.g., 6mm or 8mm). |

| Mounting Style | Panel mount for front installation; PCB mount for compact assemblies. |

| IP Rating | Choose higher IP ratings for dusty, wet, or harsh environments. |

| Push Button | Decide if you need a built-in switch for added functionality. |

| Environmental Factors | Consider operating temperature, vibration tolerance, and dust resistance. |

Buyer Checklist: Match Your Needs

- Hobby Projects: Basic incremental encoders with standard resolution and PCB mounting usually work well.

- Professional/Industrial Use: Choose durable encoders with high resolution, strong enclosures, and suitable IP ratings.

- With or Without Push Button: If your application needs menu control or user input, pick an encoder with a push button.

Why Choose Wilmall Rotary Encoders?

Wilmall rotary encoders stand out for their durable construction, designed to withstand industrial wear and tear. They also offer competitive pricing combined with excellent customer support, helping you find the right fit whether for a DIY project or heavy-duty industrial use. For added peace of mind in harsh settings, check out Wilmall’s range of industrial rotary encoders, known for reliability under tough conditions.

Choosing the right rotary encoder is easier when you know what fits your application best — and Wilmall makes sure you get quality with value.

Installation, Wiring, and Basic Usage Tips

When installing a rotary encoder, knowing the common pinouts is essential. Most encoders have pins for A and B channels (the quadrature signals), GND, VCC (power), and sometimes an additional SW pin for a built-in push button. Correct wiring ensures smooth operation and reliable data output.

To get clean signals, especially with an incremental rotary encoder, use debouncing techniques. Mechanical contacts and noise can cause signal bouncing, leading to false pulses. Adding pull-up resistors on the signal lines helps stabilize the outputs and prevent erratic readings.

For quick prototyping, connecting your rotary encoder to an Arduino is straightforward:

const int pinA = 2;

const int pinB = 3;

volatile int position = 0;

void setup() {

pinMode(pinA, INPUT_PULLUP);

pinMode(pinB, INPUT_PULLUP);

attachInterrupt(digitalPinToInterrupt(pinA), handleEncoder, CHANGE);

Serial.begin(9600);

}

void loop() {

Serial.println(position);

delay(100);

}

void handleEncoder() {

if (digitalRead(pinA) == digitalRead(pinB)) position++;

else position–;

}

This basic code tracks rotation direction and counts pulses per revolution.

Common issues like missed pulses or incorrect direction detection often result from wiring mistakes, noisy signals, or lack of proper debouncing. Double-check your wiring order and ensure stable power supply. Using filtering capacitors or software debouncing can also help.

For rugged environments, consider encoders with better sealing and cables, such as those compatible with M-series stainless steel cable glands for enhanced durability and reliable connections.

Proper installation and wiring setup are key to unlocking the precise, reliable performance that rotary encoders are known for.