The GOS38B incremental rotary encoder offers reliable and precise position and speed feedback for a wide range of industrial automation applications. Engineered with a robust 38mm diameter housing and solid 6mm shaft, this encoder provides multiple pulse resolutions tailored to meet varied control requirements. Its advanced anti-interference circuitry and rugged design ensure stable performance in harsh environments, making it ideal for motors, conveyors, packaging machinery, and CNC systems. The GOS38B is compatible with multiple control systems, delivering consistent signal output to optimize machine efficiency and accuracy.

Key Features

Incremental rotary encoder with pulse resolutions ranging from 100 to 5000 PPR (pulses per revolution)

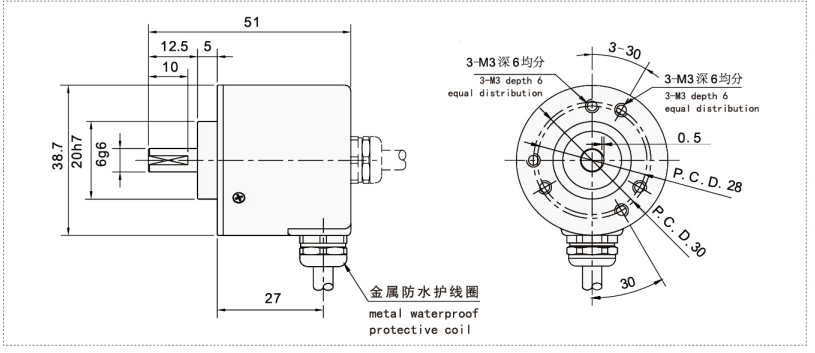

Compact 38mm diameter with 6mm solid shaft for versatile installation

Multiple output types: open collector (NPN), push-pull, and complementary outputs

Robust anti-interference circuit for stable and noise-resistant signal transmission

Wide voltage operating range (typically 5-24V DC) suitable for most industrial control systems

High mechanical durability and IP-rated housing for dust and water resistance

Compatible with various automation PLCs and speed controllers

Optional cable lengths and output configurations to customize installations

Product Advantages

High precision and resolution improve the accuracy of position and speed control

Durable and compact design withstands rugged industrial environments

Flexible output signals allow integration with various control systems

Advanced anti-interference design reduces signal noise and enhances reliability

Easy installation reduces downtime and maintenance efforts

Supports a wide range of industrial machinery and automation needs

Product model and meaning

| G | 0 | S | 38 | B | 2500 | C | 3 | 2M | ||||

| Category of product | Type of product | Form of main shaft | Contour of product | Size of main shaft,shaft hole | Outlet and sealing form | Resolution | Output form | Output signal | Cable | |||

| G:incremental type | O:megneto- electricity P:photoelec- tricity | S: solid shaft | 38:φ38mm | □:φ6mm 08:φ8mm | B: side outlet metal D:rear-outlet metal | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1200,200,2048,2500,3000,3600,5000

| M:analog quantity output C:open collector output F:complementary output T:push pulloutput L:5V drive output A:24V drive output | 1:phase A signal 2:phase AB signal 3:phase ABZ signal 4:ABA/B/ signal 5: phase ABZA/B/Z/ signal 6:420mA 7:0-5V 8:0-10V | 2Default 2m line,For non 2m, labeling is sufficient | |||

Wiring Table

| Line color | C/F/T output signal | Line color | L/A output signal | Line color | M signal(current) | Line color | M signal(voltage) | |||

| red | Vcc | red | Vcc | Brown | Vcc | Brown | Vcc | |||

| black | 0V | black | 0V | white | 0V | white | 0V | |||

| green | Aphase | green | Aphase | green | 1 | green | +U | |||

| white | B phase | white | B phase | yellow | -1 | yellow | -U | |||

| yellow | Z phase | yellow | Zphase | shield | F ·G | shield | F ·G | |||

| shield | F ·G | brown | A/phase | |||||||

| gray | B/phase | |||||||||

| orange | Z/phase | |||||||||

| shield | F ·G |

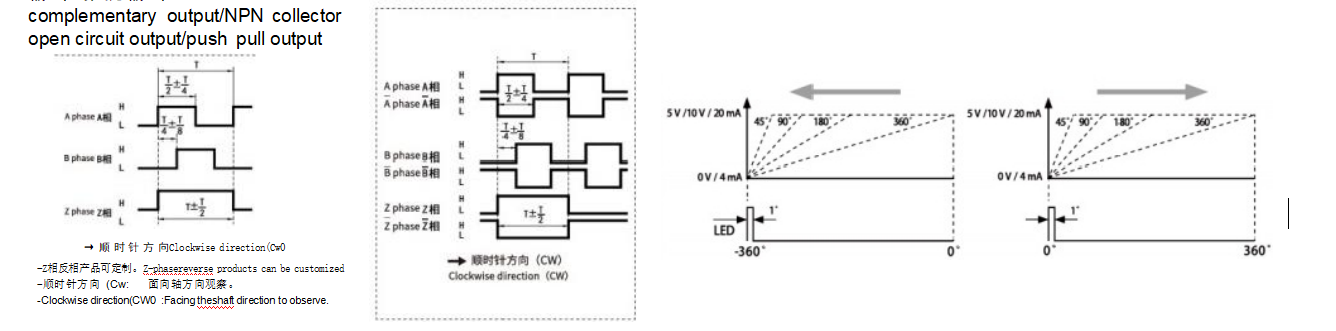

Output phase difference

Mechanical drawings(mm)

Application Scenarios

Motor speed and position feedback in industrial automation

Conveyor belt speed monitoring and control

Packaging machinery synchronization and operation

CNC equipment position sensing

Robotics for joint angle and rotational feedback

Printing machinery and assembly line automation

Installation & Maintenance

Ensure the shaft of the encoder matches the application’s coupling diameter (6mm solid shaft).

Align the encoder shaft precisely with the machine shaft; use flexible couplings to avoid misalignment stress.

Securely mount the encoder with the provided hardware to minimize vibration.

Connect power supply within the recommended voltage range (5-24V DC) following the wiring diagram.

Use shielded cables for signal wiring to prevent electromagnetic interference.

Perform regular cleaning to remove dust and debris; avoid using harsh chemicals or water jets.

Check wiring and connectors periodically for secure connections and signal integrity.

Replace the encoder if signs of mechanical wear or unstable signals arise.

Request a Quote Now

Our team will get back to you within 24 hours.