The GLT48 Incremental Rotary Encoder is engineered for high precision and long-lasting performance in demanding industrial control systems. Featuring a rugged design and stable signal output, this rotary encoder is ideal for applications requiring accurate rotational position and speed feedback. Its easy installation and low maintenance requirements make it a trusted component for automation, robotics, and machine tool industries.

Principais recursos:

High-resolution incremental output with consistent and noise-resistant signals

Robust construction designed for industrial environments with dust and vibration resistance

Versatile output signal options including TTL and open collector

Standardized flange and shaft coupling for quick and secure mounting

Premium bearings and sealed housing for extended operational life

Wide operating voltage range compatible with various industrial power supplies

Vantagens do produto:

Provides stable and precise feedback essential for optimizing machine accuracy

Rugged build reduces failure rates in harsh and continuous-use environments

Simplifies system integration with flexible output and mounting solutions

Enhances productivity by minimizing downtime and maintenance needs

Suitable for compact installations due to its space-efficient design

Product Model And Meaning

| G | L | T | 48 | □ | – | 2500 | – | 8P | – | 0.21M |

| Category of produto | Tipo de produto | Form of main shaft | Contour of produto | Size of main eixo, furo do eixo | Resolução | Formulário de saída | Cabo | |||

| G:incremental tipo | L:photoelec- tricidade | T:Through-hole shaft | 48:Φ48mm | □:φ9mm 08:中8mm | 500,1000,1024,2500 | 4P:2 pairs of magnetic poles 6P: 3pairs of magnetic poles 8P:4 pairs of magnetic poles 10P:5 pairs of magnetic poles | Default 0.21m line,For non 0.21m,labeling is sufficientt |

Tabela de fiação

| Cor da linha | output signal |

| vermelho | Vcc |

| preto | 0V |

| verde | Uma fase |

| branco | Fase B |

| amarelo | Fase Z |

| marrom | U phase |

| cinza | V |

| laranja | W |

| green black | Fase |

| white black | Fase B |

| yellow black | Fase Z |

| brown black | U phase |

| gray black | V phase |

| orange black | W phase |

| escudo | F -G |

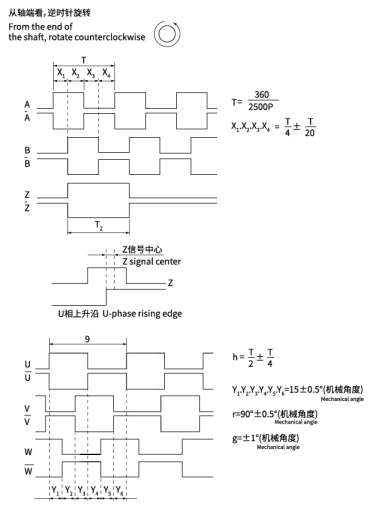

Output Phase Difference

Signal position accuracy:The absolute angle error of phase A,Bis≤0.2T, the period error is ≤0.05T,T=360°/N(N is the number of output pulses per revolution), the period P=360°/N1±1.5°(N1=2,3,4),the phase difference Yn=P/6±1.5°(n=1,2,3,4,5, 6),and the positions of phases A and B with U, V,and Ware not specified;

Relationship between Z-phase and U-phase:C ≤±1 °(mechanical

angle)

Desenhos mecânicos (mm)

Installation and Maintenance:

Attach the GLT48 encoder to the machine shaft using the supplied coupling or adapter.

Ensure correct shaft alignment to avoid mechanical wear and signal errors.

Connect wiring per the detailed wiring schematic, confirming correct connections.

Verify encoder output signals by testing with your control system hardware.

Periodically clean the encoder exterior to remove dust and debris accumulation.

Inspect mechanical couplings and connections during routine maintenance.

Detailed Product Applications:

The GLT48 encoder’s adaptability and precision make it suitable for a variety of industrial settings:

Automation lines requiring precise motor speed and position feedback

CNC milling, drilling, and turning machines for controlled machining accuracy

Robotics applications needing accurate joint and wheel position sensing

Conveyor systems for speed monitoring and material tracking

Printing presses and packaging lines to synchronize motion and improve output quality

Elevator and escalator systems for safe and smooth shaft rotation monitoring

Renewable energy equipment, including wind turbines, for blade position feedback

Medical and laboratory instruments that require high-reliability rotational input

Solicite uma cotação agora

Nossa equipe entrará em contato com você em 24 horas.