The GLS50H Rotary Encoder offers dependable and consistent rotational feedback designed for demanding machinery and automation applications. Engineered with a robust construction and versatile output options, this encoder delivers stable speed and position signals to support smooth motion tracking and system efficiency. Its durable design and ease of installation make it suitable for a wide range of industrial environments.

Основные характеристики:

High-resolution incremental output producing stable pulse signals

Rugged, sealed enclosure protecting against dust, moisture, and vibration

Supports TTL and open collector output formats for flexible integration

Standard flange mounting and shaft coupling for easy installation

Premium bearings ensure extended operating life

Wide voltage input range adapts to varied power supply requirements

Преимущества продукта:

Provides reliable and steady motion feedback for enhanced operational consistency

Heavy-duty design minimizes downtime, even in harsh environments

Flexible output and mounting options streamline system integration

Compact size allows installation in space-limited applications

Low maintenance requirements enhance overall system uptime

Модель продукта и ее значение

| G | L | S | 50 | □ | H | 1000 | T | 3 | 2M | ||||

| Категория продукт | Тип продукта | Форма главный вал | Контур продукт | Размер основного вал, отверстие вала | Outlet and форма запечатывания | Разрешение | Форма выпуска | Выходной сигнал | Кабель | ||||

| G:incremental type | L:photoelec- tricity | S: цельный вал | 50:φ50 мм | □:Φ8mm | H:rear-outlet plastic | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:выход с открытым коллектором T:push pull output L:5V 5V drive output A:24V drive output | 1:phase A signal 2:сигнал фазы AB 3:фазовый сигнал ABZ 4:фазовый сигнал ABA/B/ 6:phase ABZA/B/Z/ signal | По умолчанию 2m line,For non 2m, labeling is sufficient | ||||

Таблица проводов

| Цвет линии | C/F/T output signal | Цвет линии | L/A output signal | |

| коричневый | VCC | коричневый | VCC | |

| голубой | GND | |||

| голубой | GND | |||

| черный | Фаза | |||

| balck | Фаза | белый | Фаза B | |

| range | Фаза Z | |||

| белый | Фаза B | |||

| красный | Фаза | |||

| апельсин | Фаза Z | gray | Bphase | |

| yellow | Фаза Z | |||

| щит | F -G | |||

| щит | F -G |

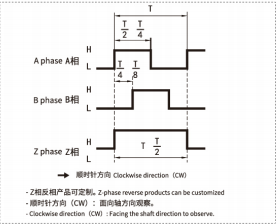

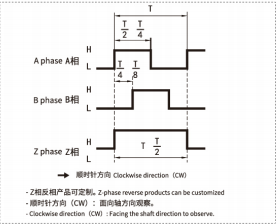

Разность фаз на выходе

complementary output/NPN collector open circuit output

longline drive output

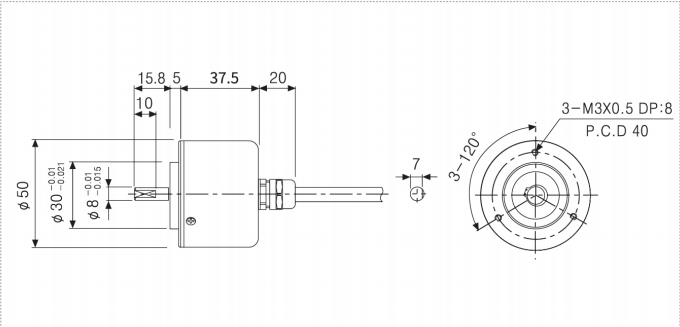

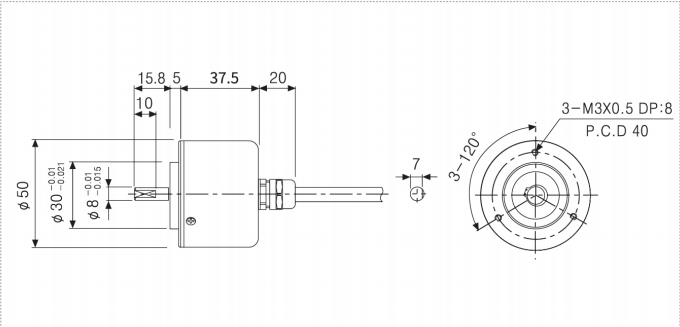

Механические чертежи (мм)

Установка и обслуживание:

Mount the GLS50H encoder securely on the shaft using the supplied coupling or adapter.

Ensure proper shaft alignment to avoid mechanical stress and inaccurate readings.

Connect wiring precisely as per the provided schematic, verifying correct power and signals.

Conduct testing of the output signals with your control system before full deployment.

Regularly clean the encoder body to prevent dust and debris buildup.

Inspect hardware and connections periodically; lubricate bearings as recommended.

Подробная информация о применении продукта:

The GLS50H encoder is suitable for a wide variety of applications, including:

Conveyor and material handling systems monitoring speed and position

Robotics and automation equipment requiring reliable motion signals

Packaging and printing machines for process synchronization

Elevators, escalators, and lifts for smooth and safe shaft monitoring

Renewable energy systems like wind turbines for blade position feedback

Agricultural machinery and heavy equipment in challenging environments

Medical and laboratory equipment requiring dependable rotation sensing

Rotary encoders like the GLS50H are critical components in enhancing motion feedback reliability across automated and mechanical systems. Advances in encoder technology focus on improving environmental resistance and signal integrity to ensure continuous operation in challenging conditions. Proper installation techniques, including alignment and wiring accuracy, significantly impact encoder longevity and performance. Integration of encoders with modern digital control platforms also enables predictive maintenance and system diagnostics, paving the way for smarter and more efficient machinery operations.

Запросить предложение прямо сейчас

Наши сотрудники свяжутся с вами в течение 24 часов.