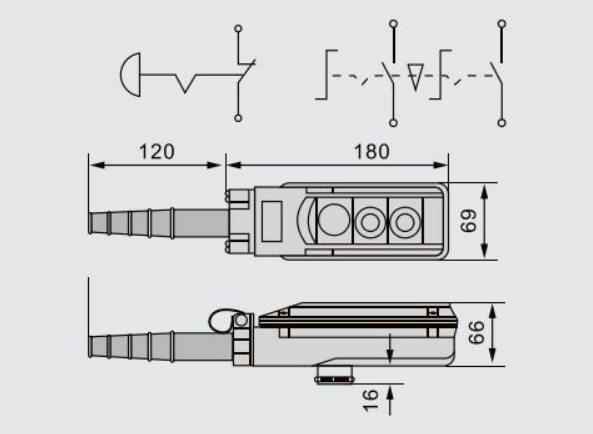

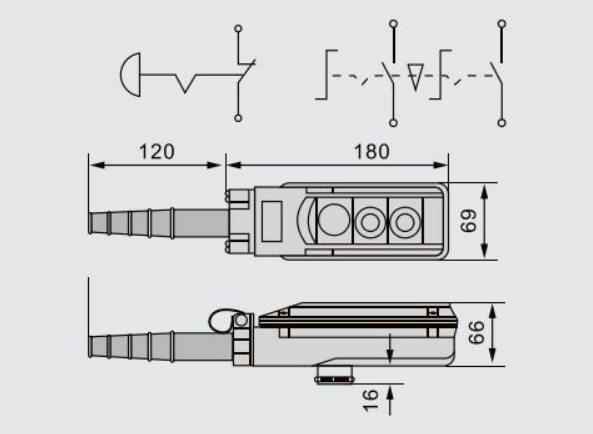

The COB-61C crane control button is a specialized multi-function mechanical control box engineered for various crane operation needs in industrial settings. Designed with robust materials, this control box offers multiple button functions in a compact, easy-to-install unit, allowing operators seamless control over crane movements. Suitable for overhead cranes, gantry cranes, and other lifting equipment, the COB-61C enables precise movement control to help improve workflow productivity and enhance workplace safety.

How It Works

The COB-61C operates through a series of mechanical push-buttons connected via internal electrical contacts. When an operator presses one of the control buttons, the corresponding circuit closes or opens, sending electrical signals to the crane’s control system. This action directs the crane to perform specific functions such as lifting, lowering, moving left/right, or stopping.

Its mechanical design relies on durable contact plates and springs to provide tactile feedback and ensure reliable switching under industrial conditions. The multi-function aspect allows multiple directional and operational commands from one compact control box.

Main Components

Mechanical Push Buttons: Heavy-duty buttons designed for repeated use, typically color-coded for ease of operation.

Control Box Housing: Sturdy enclosure made from industrial-grade materials resistant to dust, shocks, and moisture.

Electrical Contact Assembly: Copper alloy contacts for efficient current conduction and long lifespan.

Mounting Bracket: For secure attachment to crane control panels or operator cabins.

Wiring Terminals: Clearly labeled for straightforward and error-free connections.

Advantages

Multi-functional capability with several operation buttons in one unit

High mechanical durability suitable for harsh crane operating environments

Easy installation and integration into standard crane control circuits

Ergonomically designed buttons reduce operator fatigue

Reliable tactile feedback for positive input recognition

Installation Steps

Ensure the crane power supply is switched off before beginning installation.

Securely mount the COB-61C control box on the designated panel or operator console using appropriate mounting hardware.

Connect the wiring terminals according to the manufacturer’s wiring diagram, verifying phase and function labeling carefully.

Perform initial mechanical and electrical tests by manually pressing each button and confirming the corresponding crane responses.

Once tested, restore power and conduct full operational trials under supervision.

Product Applications

Overhead crane control systems in warehouses and manufacturing plants

Gantry and jib cranes for precise load handling

Hoist operation controls in construction sites and factories

Shipyard crane directional and operational control

Heavy machinery lifting controls in logistics and material handling sectors

Multi-function mechanical control units for crane retrofitting and upgrades

With enhanced safety features and ergonomic button design, the COB-61C ensures both operational efficiency and user comfort. This product is frequently searched with long-tail keywords like “multi-function crane control button COB-61C,” “COB-61C crane control box for hoist,” and “industrial mechanical crane controller switch.”

Request a Quote Now

Our team will get back to you within 24 hours.