El encóder rotativo GLS50H ofrece una respuesta rotativa fiable y coherente diseñada para aplicaciones exigentes de maquinaria y automatización. Con una construcción robusta y opciones de salida versátiles, este encóder proporciona señales de velocidad y posición estables para facilitar el seguimiento del movimiento y la eficiencia del sistema. Su diseño duradero y su facilidad de instalación lo hacen adecuado para una amplia gama de entornos industriales.

Características principales:

Salida incremental de alta resolución que produce señales de impulsos estables

Carcasa robusta y sellada que protege contra el polvo, la humedad y las vibraciones

Admite formatos de salida TTL y de colector abierto para una integración flexible

Montaje con brida estándar y acoplamiento de eje para facilitar la instalación

Rodamientos de alta calidad que prolongan la vida útil

El amplio rango de tensión de entrada se adapta a las distintas necesidades de alimentación

Ventajas del producto:

Proporciona una respuesta de movimiento fiable y constante para mejorar la coherencia operativa.

El diseño resistente minimiza el tiempo de inactividad, incluso en entornos difíciles

Las opciones flexibles de salida y montaje agilizan la integración del sistema

Su tamaño compacto permite la instalación en aplicaciones con espacio limitado

Los reducidos requisitos de mantenimiento mejoran el tiempo de funcionamiento general del sistema

Modelo de producto y significado

| G | L | S | 50 | □ | H | 1000 | T | 3 | 2M | ||||

| Categoría producto | Tipo de producto | Forma de eje principal | Contorno de producto | Tamaño del principal eje, agujero del eje | Salida y formulario de sellado | Resolución | Formulario de salida | Señal de salida | Cable | ||||

| G:tipo incremental | L:fotoelec- tricidad | S:eje macizo | 50:φ50mm | □:Φ8mm | H:salida trasera de plástico | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:salida de colector abierto T:salida push pull L:5V Salida de 5 V A:Salida de 24 V | 1:señal de fase A 2:señal de fase AB 3:fase Señal ABZ 4:fase Señal ABA/B/ 6:fase ABZA/B/Z/ señal | Por defecto 2m línea,Para no 2m, el etiquetado es suficiente | ||||

Tabla de cableado

| Color de la línea | Señal de salida C/F/T | Color de la línea | Señal de salida L/A | |

| marrón | VCC | marrón | VCC | |

| azul | GND | |||

| azul | GND | |||

| negro | Una fase | |||

| negro | Una fase | blanco | Fase B | |

| gama | Fase Z | |||

| blanco | Fase B | |||

| rojo | Una fase | |||

| naranja | Fase Z | gris | Bphase | |

| amarillo | Fase Z | |||

| escudo | F -G | |||

| escudo | F -G |

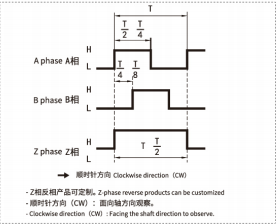

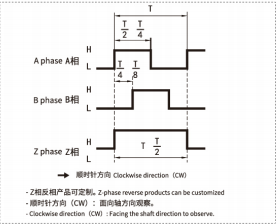

Diferencia de fase de salida

salida complementaria/Salida de circuito abierto de colector NPN

salida de palangre

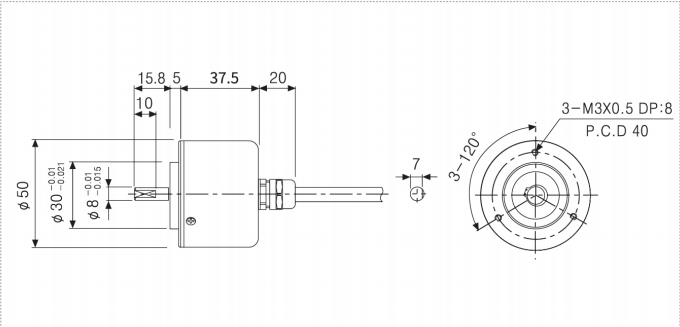

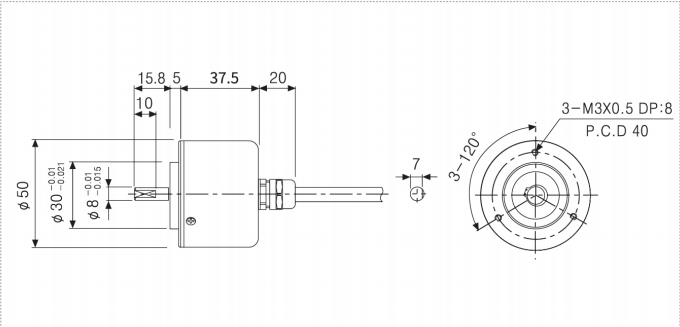

Dibujos mecánicos(mm)

Instalación y mantenimiento:

Monte el encoder GLS50H firmemente en el eje utilizando el acoplamiento o adaptador suministrado.

Asegúrese de que el eje está correctamente alineado para evitar tensiones mecánicas y lecturas inexactas.

Conecte el cableado con precisión según el esquema suministrado, verificando la alimentación y las señales correctas.

Realice pruebas de las señales de salida con su sistema de control antes del despliegue completo.

Limpie regularmente el cuerpo del codificador para evitar la acumulación de polvo y suciedad.

Inspeccione periódicamente los herrajes y las conexiones; lubrique los cojinetes según las recomendaciones.

Aplicaciones detalladas del producto:

El encóder GLS50H es adecuado para una amplia variedad de aplicaciones, entre las que se incluyen:

Sistemas de transporte y manipulación de materiales que controlan la velocidad y la posición

Robótica y equipos de automatización que requieren señales de movimiento fiables

Máquinas de envasado e impresión para la sincronización de procesos

Ascensores, escaleras mecánicas y ascensores para un control de huecos suave y seguro

Sistemas de energía renovable como las turbinas eólicas para retroalimentar la posición de las palas

Maquinaria agrícola y equipos pesados en entornos difíciles

Equipos médicos y de laboratorio que requieren una detección de rotación fiable

Los encóderes rotativos como el GLS50H son componentes fundamentales para mejorar la fiabilidad de la realimentación de movimiento en sistemas mecánicos y automatizados. Los avances en la tecnología de encóderes se centran en mejorar la resistencia ambiental y la integridad de la señal para garantizar un funcionamiento continuo en condiciones difíciles. Las técnicas de instalación adecuadas, incluidas la alineación y la precisión del cableado, influyen significativamente en la longevidad y el rendimiento de los encóderes. La integración de los encóderes con las modernas plataformas de control digital también permite el mantenimiento predictivo y el diagnóstico del sistema, allanando el camino para unas operaciones de maquinaria más inteligentes y eficientes.

Solicite un presupuesto ahora

Nuestro equipo se pondrá en contacto con usted en un plazo de 24 horas.