Aviation Connector Plug Guide with Specifications and Buying Tips

Discover high-quality aviation connector plugs with threaded locking, waterproof options, multiple pin configurations, and rugged metal construction.

Read More

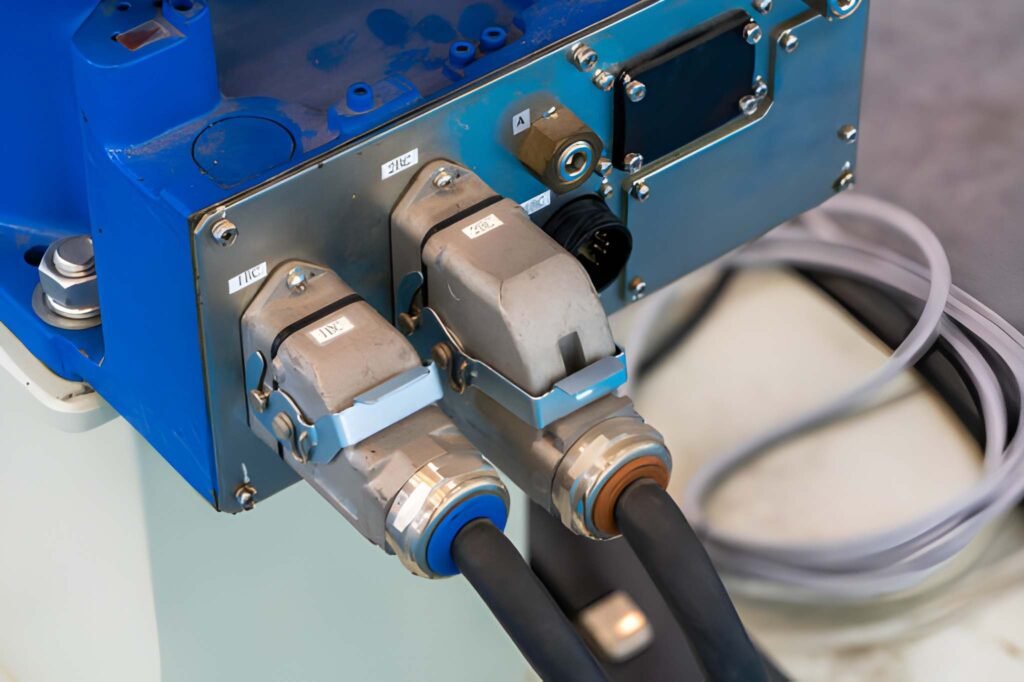

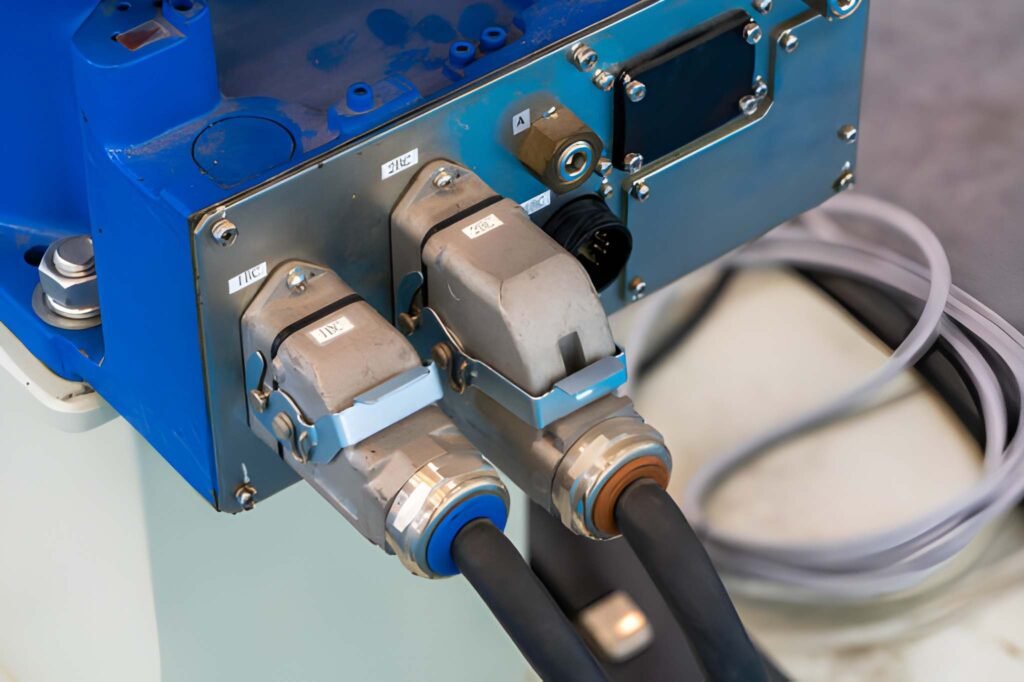

If you’re working in industrial automation, outdoor equipment, or marine tech, you know that a solid connection can make or break your project. That’s why Aviation Connector waterproof solutions have become essential—offering rugged, reliable connections that stand up to harsh environments where dust, water, and vibration are constant challenges. But what exactly sets these connectors apart? And how do you pick the right type with the perfect IP rating for your needs? In this guide, you’ll get clear, expert insights on waterproof aviation connectors, so you can choose the best fit—whether you’re powering LED lighting, securing sensors, or running underwater systems. Ready to level up your connections? Let’s dive in!

When you hear LD20 Series aviation connectors, think of robust circular plugs and sockets originally designed for aerospace applications. These connectors are built to handle demanding environments — which is why they’ve become popular beyond aviation, widely used in industrial settings where reliability matters.

Waterproof aviation connectors take this a step further by incorporating special sealing features to keep out water, dust, and other contaminants. Unlike standard connectors, they use rubber gaskets, O-rings, and durable housings made from materials like PA66 nylon or zinc alloy to ensure a tight, waterproof seal.

Here’s what sets waterproof aviation connectors apart:

Some common types you’ll encounter include:

Each type balances size, pin configuration, and waterproof capability, making them suitable for a broad range of outdoor and industrial applications. Whether you need a panel mount aviation plug or a fully sealed inline connector, waterproof aviation connectors provide durability and performance you can trust.

When choosing waterproof aviation connectors, knowing the difference between IP67 and IP68 ratings is key. Both ratings guarantee full protection against dust, but they vary in water immersion capabilities.

In real-world use, IP67 connectors suit harsh environments where exposure to moisture and dust is frequent but not constant immersion. In contrast, IP68 connectors provide peace of mind in applications such as underwater robotics or renewable energy systems where connectors are regularly submerged.

Long-term waterproof reliability depends on factors beyond ratings, including seal quality, material durability, and proper assembly. Over time, wear or improper installation can compromise the seal, reducing the connector’s effectiveness in keeping out moisture.

Choosing the right IP rating combined with rugged design ensures your aviation connector stays protected under tough conditions, maintaining performance and safety. For rugged sensors and actuators in industrial settings, you might check out reliable options like the proximity switch shielded M8 to complement your waterproof connectors.

When choosing a waterproof aviation connector, several key features make a big difference in performance and compatibility. Here’s what to keep in mind:

| Feature | Details | Notes |

|---|---|---|

| Pin Configurations | 2-pin up to 12-pin and more | Select based on signal/power needs |

| Materials | PA66 nylon, zinc alloy, brass with gold-plated contacts | Ensures durability, corrosion resistance, and low contact resistance |

| Coupling Mechanisms | Threaded, bayonet, push-pull | Threaded connectors (like GX or SP series) offer secure sealing; bayonet and push-pull are quick-lock options |

| Electrical Ratings | Voltage and current ratings vary by model | Check specs based on your device’s power requirements |

| Contact Resistance | Low resistance contacts improve signal quality | Gold plating helps reduce oxidation and maintain connectivity |

| Cable Compatibility | Supports different cable diameters and types | Confirm compatibility with your cable thickness and type |

| Mounting Options | Panel mount, inline, field-installable | Choose mounting style based on installation environment |

These specs help ensure you pick the right industrial aviation socket whether you need a compact M12 waterproof plug, a rugged GX16 aviation connector, or a specialized circular waterproof connector for tough environments.

For tailored solutions and reliable specification details, check out our detailed selection at wilmall’s aviation connector range. This helps you find the perfect fit for your specific applications.

Waterproof aviation connectors bring a host of advantages, especially when working in tough conditions. Here’s why they stand out:

Enhanced DurabilityDesigned to resist moisture, dust, vibration, and temperature extremes, these connectors excel in harsh environments. Their rugged materials and sealing mechanisms protect against corrosion and wear, making them reliable over long periods.

Improved Safety and Signal IntegrityWith tight waterproof seals and high-quality gold-plated contacts, these aviation plugs maintain stable power and data transmission. This reduces the risk of shorts, signal loss, and equipment failure.

Cost SavingsDurable construction means less frequent replacements and repairs, lowering maintenance costs and minimizing downtime. This is especially valuable in industrial and outdoor applications where service access can be difficult.

Versatility Across Industries Waterproof aviation connectors fit a range of uses — from industrial automation and outdoor electrical connectors to marine and renewable energy projects. Their multi-pin options and varied coupling styles (threaded, bayonet, push-pull) make them adaptable for different setups.

| Benefit | Explanation | Keyword Focus |

|---|---|---|

| Durability | Resistant to moisture, dust, vibration | rugged design, harsh environment connector |

| Safety & Signal Quality | Stable connections with gold-plated contacts | gold-plated contacts connector, aviation plug |

| Cost Effectiveness | Reduced maintenance and downtime | waterproof aviation connectors |

| Industry Versatility | Fits many sectors and applications | industrial aviation socket, outdoor electrical connector |

Choosing quality waterproof connectors like the SP13 waterproof connector or M12 waterproof plug ensures performance and peace of mind in your projects. For reliable options, consider trusted suppliers such as wilmall for superior craftsmanship and customization.

For installation and product details that boost efficiency and safety, also check out related products like our miniature circuit breakers to protect your systems.

Waterproof aviation connectors are trusted across a wide range of industries thanks to their ruggedness and reliable sealing. In industrial automation, these connectors are widely used with sensors and actuators where moisture, dust, and vibration are common. Their durability ensures consistent signal and power transmission even in harsh factory conditions.

For outdoor LED lighting and security systems, these circular waterproof connectors provide a dependable link that withstands weather exposure. Whether it’s constant rain, dust, or temperature swings, aviation connectors like the GX16 or SP13 series keep setups safe and functional.

In the marine and underwater equipment world—think remotely operated vehicles (ROVs) and underwater sensors—waterproof aviation plugs rated at IP68 protect sensitive electronics from immersion. Their robust sealing is perfect for salty, wet environments where reliability is critical.

Renewable energy systems, including solar panels and wind turbines, also rely on these connectors. They handle outdoor exposure and vibrations well, making them ideal for transmitting power and data in remote setups.

Finally, industries like robotics, medical devices, and communication systems use waterproof aviation connectors for secure and stable connections. The multi-pin waterproof sockets and panel mount aviation plugs offer flexible configurations for complex devices needing dependable signal integrity.

For harsh environments, pairing these connectors with accessories like high-quality stainless steel cable glands can further improve waterproofing and strain relief, ensuring long-term performance.

Picking the right waterproof aviation connector doesn’t have to be tricky. Here’s a clear step-by-step guide to help you pick the best fit for your needs:

Outdoor or indoor? For wet, dusty, or rough locations, look for connectors with at least IP67 or IP68 ratings.

Exposure level: Will it be submerged, splashed, or just exposed to humidity? This affects the IP rating and sealing type you need.

Pin count: Choose from 2-pin up to 12-pin or more, depending on how many signals or power lines you need.

Voltage and current: Match connector specs to your system’s electrical ratings to ensure safety and performance.

Connector type: Confirm male/female pairing and if it’s panel mount, inline, or field-installable.

Cable diameter: Make sure the connector fits your cable size for a tight seal and proper strain relief.

For typical outdoor use, IP67 (dust-tight and water-resistant up to 1m immersion) is enough.

For more extreme conditions or underwater use, go for IP68 plugs which allow longer and deeper immersion.

Avoid ultra-cheap knockoffs—they often skimp on materials like PA66 nylon or gold-plated contacts, risking early failure.

Investing in proven brands saves money long term by reducing maintenance and downtime.

For more on matching connectors to device cables, check out our PG9 cable gland German thread specifications guide to ensure perfect fits.

| Step | Key Question | What to Look For |

|---|---|---|

| Environment | Where will it be used? | IP67/IP68 rating, rugged materials |

| Pin Requirements | How many connections needed? | 2 to 12+ pins, voltage/current specs |

| Compatibility | Male/female, cable diameter | Matching connector and cable sizes |

| IP Rating | Degree of water/dust protection | IP67 for outdoor, IP68 for submersion |

| Budget & Quality | Balance cost and reliability | Avoid cheap knockoffs, trust well-known makers like wilmall |

This approach guarantees you get the best performance and durability for your waterproof aviation connector needs.

Getting your waterproof aviation connector installed right is key to keeping it reliable over time. Here are some straightforward tips to make sure your aviation plug stays sealed and functional:

Proper Assembly: Follow the manufacturer’s instructions closely. Ensure all seals, O-rings, and gaskets are correctly positioned before locking the connector. Avoid forcing parts together, which can damage the sealing surfaces.

Soldering and Wiring: Use quality solder and avoid cold joints by heating both the wire and contact properly. Crimped contacts should be tight and secure without over-compression. This helps maintain low contact resistance and signal integrity.

Sealing Techniques: After wiring, apply waterproof sealant or heat shrink tubing where recommended. Make sure cable glands are tightened correctly to prevent entry points for moisture or dust.

Common Mistakes to Avoid:

Testing Waterproof Integrity: Simple water spray or immersion tests after assembly can reveal weak points. Professional IP testing equipment or dye penetration methods offer more thorough sealing verification.

Longevity Best Practices:

Following these tips helps your circular waterproof connector perform well in harsh conditions, reducing downtime and costly repairs. For detailed product-specific installation advice, products like the SD20 series connectors from wilmall come with clear guides and durable designs, easing your installation and maintenance process.

At wilmall, we offer a solid range of waterproof aviation connectors designed for reliable, rugged use in tough environments. Here are some popular models known for their durability, sealing, and easy installation—perfect for industrial and outdoor applications.

| Model | Pins | IP Rating | Coupling Type | Material | Common Uses |

|---|---|---|---|---|---|

| LD16 Series | 2 to 12 pins | IP67 | Threaded | PA66 Nylon | Industrial automation, sensors LD16 Series Aviation Connector |

| SP13 | 3 to 7 pins | IP67/IP68 | Bayonet | Zinc Alloy | Outdoor LED, security systems |

| GX16 | 3 to 12 pins | IP67 | Threaded | Brass, gold-plated contacts | Marine equipment, robotics |

| M12 Series | 3 to 12 pins | IP67/IP68 | Push-pull | Zinc Alloy | Communication systems, panel mount |

By going with wilmall, you get a tested, quality industrial aviation socket or plug that reduces downtime and maintenance costs. To explore these options in detail, check out our LD16 Series Aviation Connector or our versatile range of panel mounting and inline connectors.

If you need corrosion resistance for cables, also consider pairing these with our stainless steel cable glands, ensuring complete system waterproofing and durability.

Choosing wilmall means investing in proven quality and reliable waterproof aviation connectors suited for demanding conditions worldwide.