安全な距離から、巨大な産業用クレーンを正確かつ簡単にコントロールできることを想像してみてください。それはまさに 天井クレーン遠隔操作

建設現場で鉄骨を持ち上げている場合でも、倉庫でかさばる荷物を移動させている場合でも、このワイヤレス技術により、オペレーターは危険から離れ、遠隔操作で完全な指揮を執ることができます。この記事では、天井クレーンの遠隔操作とは何か、どのように機能するのか、その利点、技術的特徴、一般的なタイプ、主要な安全機能について説明します。また、この技術がどのような産業でどのように使用されているのか、そして将来はどうなるのかを探ります。

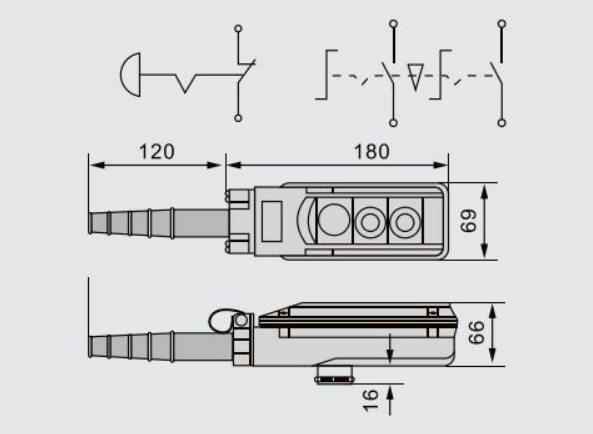

天井クレーンの遠隔操作とは? 端的に言えば、だ、 COP-AS3 天井クレーンの遠隔操作は、オペレーターが携帯機器を使用して離れた場所からクレーンを管理できるワイヤレスシステムです。オペレーターは、コントロールキャビンに縛り付けられたり、ケーブルでつながれたりする代わりに、遠隔操作装置を使用します。 無線周波数 (RF)トランスミッターで、クレーンに取り付けられたレシーバーに直接コマンドを送信する。

このセットアップにより、自由に動き回ることができ、安全性を損なうことなく、より良い視界と、より安全な昇降・横行作業のコントロールが可能になる。

主な特徴

特徴 説明 ワイヤレス操作 ケーブルをなくし、機動性を向上 リアルタイム制御 素早いレスポンスと正確な動き レンジ 一般的な動作距離は100~200m セキュリティ 信号の暗号化により不正使用を防止 汎用性 各種クレーンに対応

クレーンの制御システムのアップグレードをお考えなら、遠隔制御技術が賢い選択です。お客様のニーズに合わせたソリューションについては、お気軽にお問い合わせください。

天井クレーンの遠隔操作の仕組み この技術の核心は、2つの部品間のコミュニケーションにある:

送信機 :ボタン、ジョイスティック、またはレバーを備え、オペレーターが使用するハンドヘルド機器。レシーバー :クレーンに設置し、無線コマンドを正確な機械的動作に変換します。送信機のボタンを押したり、ジョイスティックを動かしたりすると、暗号化された無線信号が送信され、受信機が瞬時に解読します。その後、受信機がモーターやブレーキを駆動してクレーンの構成部品を動かし、荷を持ち上げたり、下ろしたり、横切ったりします。

テクニカル・ハイライト

テクノロジー 目的 自動周波数ホッピング 他のワイヤレス機器からの干渉を回避 暗号化 許可されたトランスミッターのみがクレーンを制御できるようにします。 リアルタイム信号モニタリング 切断を検知してクレーンを安全に停止 長距離走行 200mまでの一般的な範囲をサポート

このような技術的な安全策を組み合わせることで、以下のことが保証されます。 信頼性の高いセキュアなコントロール 毎回ご興味がおありですか?お客様の業務に最適な範囲と機能を備えたシステムを選ぶお手伝いをいたします。

天井クレーン遠隔操作のメリット 1.安全性の向上 遠くから操作する: 動いている荷物、危険地帯、挟まれやすい場所には近づかないこと。より良い視界: 自由に動いて、最も安全でクリアな角度を見つけ、荷物をコントロールする。ケーブルもなく、つまずくこともない: ワイヤレスは職場の危険を減らす。即座にシャットダウン: 緊急停止ボタンはリモコンに内蔵されており、素早く操作できる。2.効率と生産性の向上 より速い荷役作業: 即座に対応することで、ロードサイクルを短縮することができる。ダウンタイムが少ない: オペレーターはキャビンに乗り降りする必要がない。マルチマシン・コントロール: 複数のクレーンを操作できるリモコンもあります。3.より高い精度と柔軟性 ファインコントロール: ジョイスティックは小さく繊細な動きを可能にする。カスタムセットアップ: システムは、特定のタイプのクレーンや作業ニーズに合わせることができる。4.コスト削減 人件費の削減: 業務管理に必要な労働者の数が減る。摩耗の軽減: 精密なコントロールは、機械的な負担を軽減する。保険給付: より安全なオペレーションは保険料を下げることができる。簡単に紹介しよう:

ベネフィット インパクトの例 安全性 40%、ワイヤレス・サイトでのクレーン事故報告が減少 効率性 最大30%のサイクルタイム短縮 コスト削減 メンテナンスと人件費の削減

現場の安全性と生産性の向上をお考えですか?ワイヤレス制御パッケージについてご相談ください!

天井クレーンのリモコンの種類 シンプルな操作性をお求めの方にも、高度な機能をお求めの方にも、最適なリモートタイプがあります:

タイプ 説明 最適 プッシュボタンリモート 基本的な機能を操作するための耐久性のあるボタン 基本的なリフト作業 ジョイスティック・リモート 精密な多軸アナログ制御 複雑で繊細な荷役 タンデムコントロール 複数クレーンの同期制御 チームワークが必要な重い/厄介な荷物 カスタムソリューション オートメーションシステムとの統合に対応 ユニークな産業用ワークフロー

適切なリモートの選択は、ワークフローの効率に劇的な影響を与えます!

主な安全機能 安全性が最も重要です。最新のリモコンには

自動リンク監視: リモコンが圏外の場合、クレーンを停止します。暗号化された認証: クレーンを操作できるのは登録ユーザーだけです。緊急停止: 一回押すと、すべてのクレーンの動きが即座に停止する。周波数ホッピング: ノイズの多い環境でも信号をクリアに保ちます。オペレーターのトレーニングとサポート ベンダーは多くの場合、安全な使用を最大化するためのトレーニングを提供している。安全機能 目的 レンジモニタリング リモコンエリア外での操作を防止 アクセス・コントロール 不正使用の防止 緊急停止ボタン 緊急時に即座にシャットダウン 信号の暗号化 信号のハッキング/妨害から保護

クレーン制御装置をアップグレードする際は、常に認証された安全機能を優先してください。選定にお困りですか?お問い合わせください!

オーダーメイドのソリューションについては、今すぐお問い合わせください! 信頼性の高い当社の天井クレーンリモートコントロールで、クレーン作業をアップグレードしましょう。産業効率化のために設計されたワイヤレスクレーン制御システムで、安全性と生産性を高めてください。

業界を超えたアプリケーション 天井クレーンのリモコンは、その威力を遺憾なく発揮している:

製造: 組立ラインで重い部品を動かす建設: 梁と材料を正確に配置する。倉庫管理とロジスティクス 狭い場所での箱の取り扱いを効率的に。重工業: 造船所、製鉄所、発電所では、非常に大きなものや危険なものを管理している。産業 使用例 製造業 組立ラインでの部品取り扱い 建設 現場でのビーム位置決め 倉庫管理 パレットの積み上げと取り出し 製鉄所 溶鋼の安全な移動

アップグレードの準備はお済みですか?私たちの専門家は、あなたの特定の業界向けのソリューションをカスタマイズすることができます。

天井クレーン遠隔操作の将来動向 クレーン制御の世界は急速に進化しています。目が離せない:

スマートコントロール: リアルタイムデータと予知保全のためのIoTとの統合。オートメーション: より多くのクレーンが半自動で働き、人間が遠隔監視するようになるだろう。ユーザーインターフェースの強化: タッチスクリーン、ビデオフィードバック、ボイスコマンドも近いうちに登場するかもしれない。トレンド 潜在的なメリット IoTインテグレーション モニタリング、診断、安全性データの向上 半自律運転 効率の向上とヒューマンエラーの削減 高度なユーザーインターフェース コントロールとトレーニングが容易

天井クレーン・リモコン COB-61C テクノロジーは、安全性と効率性のギャップを埋めます。移動性と精度でオペレーターに力を与え、力仕事をより安全でスムーズなプロセスに変え、最終的には産業全体の生産性を向上させます。

新たなスタートを切るにせよ、既存のシステムをアップグレードするにせよ、ワイヤレスクレーン制御を採用することは、業務の将来に対する賢明な投資です。

よくあるご質問 一般的な最大制御範囲は? システムや環境にもよるが、通常は100~200メートル程度。

ワイヤレス・コントロールの安全性は? 暗号化、緊急停止、リンク監視などの機能により、信頼性の高い運用が可能です。

ボタン式リモコンとジョイスティック式リモコンの使い分けは? 単純なオン/オフの作業ならボタンで十分だし、正確で多方向への動きならジョイスティックが優れている。

このリモコンはすべてのクレーンタイプに対応していますか? ほとんどのシステムは様々なクレーン(EOT、ガントリー、ジブ)をサポートしていますが、互換性は常に確認してください。