GOS5008A01インクリメンタルロータリエンコーダは、さまざまな機械やオートメーションシステムに適した堅牢な設計で、信頼性の高い回転フィードバックを提供します。複数の出力形式と高い耐久性を提供するこのエンコーダは、効率的なモーショントラッキングのための一貫した速度と位置データを保証します。堅牢な構造と統合の容易さにより、厳しい操作環境にも高い適応性を発揮します。

主な特徴

安定したパルス信号を出力する高分解能インクリメンタル出力

埃、湿気、振動から保護する頑丈な密閉設計

TTLおよびオープンコレクタ出力形式をサポートし、多様なシステム統合に対応

標準的なフランジ取り付けとシャフトカップリングによる簡単な取り付け

プレミアム・ベアリングと密閉型エンクロージャーによる長寿命化

各種電源に対応する広い電圧入力範囲

製品の利点:

モーション・モニタリングの精度を高めるため、信頼性の高い安定したフィードバックを提供

耐久性に優れた構造により、過酷な使用環境下でのダウンタイムを最小限に抑えます。

柔軟な取り付けと出力オプションにより、容易な適応性を実現

リアルタイムの回転データを提供することで、機械の効率を向上

コンパクトな設計で、スペースに制約のある装置セットアップに対応

製品モデルとその意味

| G | 0 | s | 50 | 08 | A | 01 | 1000 | C | 3 | 2M | |||

| カテゴリー 製品 | 製品の種類 | フォーム メインシャフト | 輪郭 製品 | メインシャフト、シャフト穴のサイズ | アウトレット シーリングフォーム | 概要構成 | 決議 | 出力形式 | 出力信号 | ケーブル | |||

| G:インクリメンタル タイプ | O:メガネット電力 | S:ソリッドシャフト | 50:φ50ミリ | 08:φ8mm | A:サイドアウトレットゴム | 01:1の概要 構造1 | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024, 1200,2000 2048,2500, 3000,3600, 4096 | F:相補出力 L:5Vドライブ出力 A:24Vドライブ出力 | 1:位相信号 2:AB相信号 3:位相ABZ信号 4:位相ABA/B/信号 6:ABZA/B/Z/相信号 | デフォルト 2m 2mでない場合、ラベリングは十分である。 | |||

配線表

| ラインカラー | C/F/T出力信号 | ラインカラー | L/A出力信号 | |

| ブラウン | ブイシーシー | ブラウン | ブイシーシー | |

| 青 | GND | |||

| 青 | GND | |||

| ブラック | A段階 | |||

| ブラック | A段階 | ホワイト | Bフェーズ | |

| オレンジ | Z相 | |||

| ホワイト | Bフェーズ | |||

| ブラックレッド | A段階 | |||

| オレンジ | Z相 | ホワイトレッド | Bフェーズ | |

| オレンジレッド | Z相 | |||

| シールド | F -G | |||

| シールド | F -G |

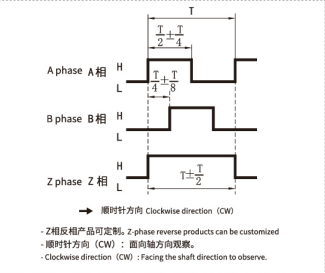

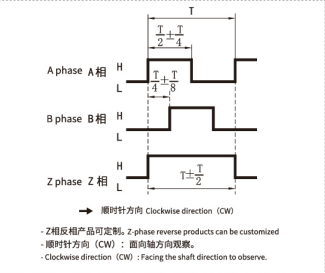

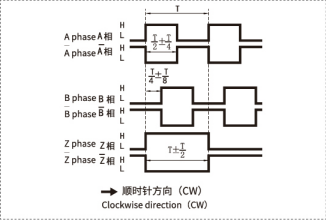

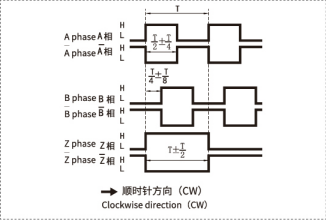

出力位相差

相補出力

ロングライン・ドライブ出力

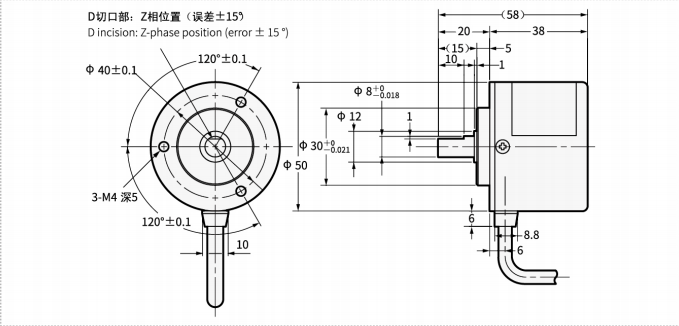

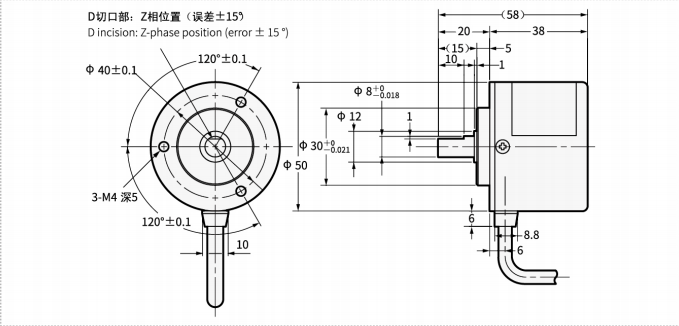

機械図面(mm)

インストールとメンテナンス:

付属のカップリングまたはアダプタを使用して、GOS5008A01 エンコーダを装置のシャフトにしっかりと取り付けます。

機械的ストレスや信号の不正確さを避けるため、エンコーダシャフトの位置合わせは慎重に行ってください。

提供された回路図に基づいて配線を接続し、電源と信号が正しく接続されていることを確認する。

本運転の前に、コントロールシステムまたはモニタリングシステムで出力信号をテストしてください。

エンコーダのハウジングを定期的に清掃し、ほこりや汚れの付着を防いでください。

取り付け金具および電気接続部を定期的に点検し、推奨される潤滑剤を塗布する。

詳細な製品用途

以下のような様々な機器や環境に適している:

正確な速度と位置のフィードバックを必要とするコンベアとマテリアルハンドリングシステム

一貫したモーションデータを必要とするロボットや自動機器

同期化と品質管理のための印刷・包装機械

信頼性の高いシャフト回転監視のためのエレベーターとエスカレーターシステム

ブレード位置トラッキング用風力タービンを含む再生可能エネルギー・アプリケーション

厳しい環境条件にさらされる農業機械や重機械

信頼性の高いモーションフィードバックを必要とする医療機器および検査機器

GOS5008A01 のようなロータリーエンコーダは、モーション精度と信頼性を向上させることで、自動化システムを進歩させる上で極めて重要です。エンコーダのシーリング技術と信号処理における継続的な技術革新は、過酷な環境と厳しいアプリケーションでの性能を強化し続けています。エンコーダの寿命と出力品質を最大限に高めるには、シャフトの位置合わせや配線の完全性など、適切な取り付けが重要な役割を果たします。さらに、エンコーダを最新のデジタル制御システムに統合することで、予知保全と性能分析が可能になり、よりスマートで効率的な機械運転に貢献します。

今すぐ見積もりを依頼する

24時間以内にご返信いたします。