について COP-A2B Emergency Stop Button Control Box Remote Control is engineered to provide fast, efficient emergency stop functions that can be activated remotely or locally. This device integrates seamlessly with various automated systems to halt operations instantly, preventing accidents and minimizing downtime. Featuring durable construction and intuitive design, it supports enhanced control with remote activation capabilities, making it suitable for machinery, conveyor belts, assembly lines, and production systems where safety is paramount.

動作原理

The COP-A2B control box works on a simple but reliable principle: when the emergency stop button is pressed—either directly on the control box or via its remote control—the control circuit immediately interrupts power to connected machinery or equipment. This interruption forces an instant cessation of all mechanical movements to prevent injury or damage. The design ensures that once activated, the system stays off until manually reset, avoiding accidental restart and ensuring compliance with safety regulations.

主要コンポーネント

緊急停止ボタン: Large, red, mushroom-shaped for easy activation by hand or palm.

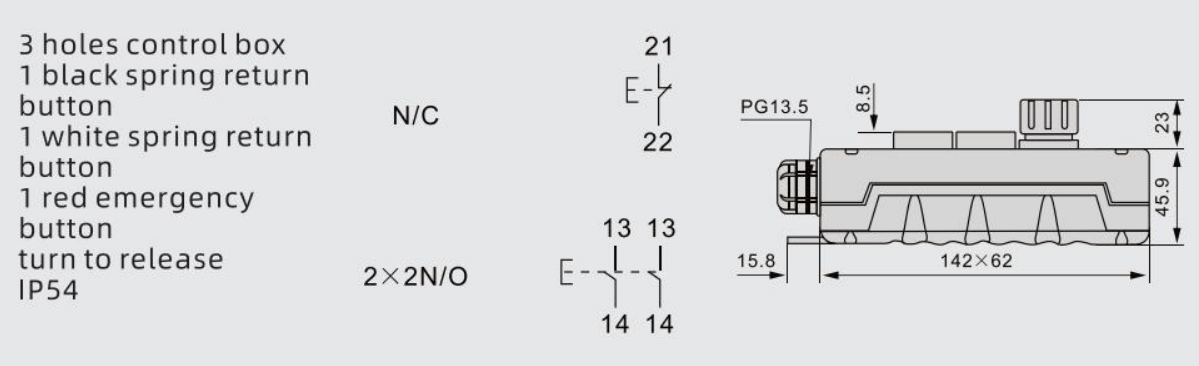

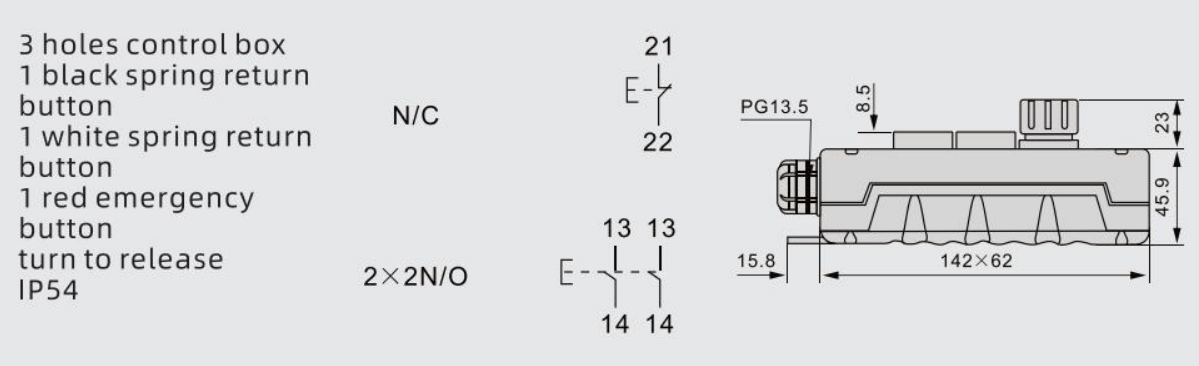

Control Box Housing: Durable, impact-resistant enclosure with IP-rated protection.

Remote Control Module: Wireless transmitter enabling remote emergency stop commands.

Electrical Relay: Acts as the switch to cut power output on activation.

Indicator Light (optional): Shows system status for easy monitoring.

Reset Mechanism: Manual reset switch to restore normal operation post-emergency.

メリットとデメリット

メリット

Quick and reliable emergency stop function that can be triggered remotely.

Improves workplace safety in hazardous industrial environments.

Robust, IP-rated enclosure prevents damage from dust and moisture.

Easy to install and integrate with existing control systems.

Reduces risk of equipment damage and personnel injury.

Manual reset ensures controlled restart after emergencies.

デメリット

Requires periodic maintenance to ensure button responsiveness.

Remote control limited by wireless signal range and potential interference.

May need customization for specific machinery compatibility in complex systems.

Installation and Maintenance Steps

Installation:

Mount the control box firmly in an accessible and visible location near the equipment.

Connect wiring from the control box to the emergency power cut circuits of the machinery following the product wiring diagram.

Pair and test the remote control functionality to confirm signal reception.

Label the emergency stop button clearly for quick identification.

Conduct a system test to verify shutdown and reset processes.

Maintenance:

Regularly inspect the emergency stop button for wear and damage.

Test remote control signal strength and replace batteries as needed.

Clean the control box surface and ensure no dust or debris obstructs components.

Verify electrical connections quarterly for corrosion or looseness.

Perform functional tests monthly to keep the emergency stop mechanism responsive.

製品用途

Industrial manufacturing assembly lines

Conveyor systems in warehouses and distribution centers

Heavy machinery operation in factories

Automated packaging and processing machines

Robotics safety shutdown systems

Remote-controlled machinery emergency stops

今すぐ見積もりを依頼する

24時間以内にご返信いたします。