The GOS38E incremental rotary encoder delivers exceptional precision and durability for industrial automation and motion control applications. Engineered with robust IP67-rated housing, this encoder excels in harsh environments with strong dust and water resistance. It features multiple pulse resolutions and reliable push-pull signal output, offering stable and accurate position and speed feedback. Ideal for motors, conveyor systems, robotics, and packaging machinery, the GOS38E supports seamless integration thanks to its compact 38mm diameter and versatile mounting options.

Key Features:

Incremental encoder with high resolution options (up to 5000 P/R) for fine motion detection

IP67 rated protection ensures superior resistance against dust and water ingress

Compact 38mm diameter housing fits tight mechanical spaces

Wide supply voltage range from 5V to 24V DC for flexible compatibility

Push-pull output signals enable robust electromagnetic interference resistance

High-frequency response for precise speed and position measurements

Solid shaft and hollow shaft variants available

Rugged design suitable for industrial environments

Wide operating temperature range covers typical industrial conditions

製品の利点:

High precision and reliable incremental signals improve machine control accuracy

Robust IP67 housing extends product life in challenging applications

Compact size supports installation in space-constrained setups

Flexible output formats and multiple resolutions for customized configuration

Easy integration with various automation systems and motor controls

Durable construction reduces downtime and maintenance costs

製品モデルとその意味

| G | 0 | S | 38 | E | 600 | F | 3 | 2M | ||||

| カテゴリー 製品 | 製品の種類 | フォーム メインシャフト | 輪郭 製品 | メインのサイズ シャフト、シャフトホール | アウトレット シーリングフォーム | 決議 | 出力形式 | 出力信号 | ケーブル | |||

| G:インクリメンタル タイプ | O:megneto- 電気 | S:ソリッドシャフト | 38:φ38mm | φ6mm | E:side outlet metal | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,5000 | C:open collector output F:相補出力 T:プッシュプル出力 L:5Vドライブ出力 A:24Vドライブ出力 | 1:位相信号 2:AB相信号 3:位相ABZ信号 4: phase ABA/B/ signal 6:ABZA/B/Z/相信号 | デフォルト 2m 2mでない場合、ラベリングは十分である。 | |||

配線表

ラインカラー | C/F出力信号 | – | ラインカラー | L/A出力信号 |

| 赤 | ブイシーシー | 赤 | ブイシーシー | |

| ブラック | GND | |||

| ブラック | GND | |||

| グリーン | A段階 | |||

| グリーン | A段階 | ホワイト | Bフェーズ | |

| イエロー | Z相 | |||

| ホワイト | Bフェーズ | |||

| ブラウン | 相 | |||

| イエロー | Z相 | 灰色 | B相 | |

| オレンジ | Z相 | |||

| シールド | F -G | |||

| シールド | F -G |

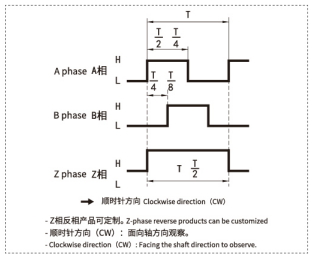

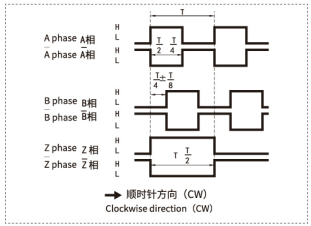

出力位相差

出力/NPNコレクタオープン回路出力

ロング・ライン・ドライブ出力

機械図面(mm)

Installation & Maintenance:

Ensure the mounting surface is clean and free of debris before installation.

Align the encoder shaft carefully with the driven shaft to avoid misalignment. Use flexible couplings if necessary to reduce mechanical stress.

Secure the encoder with supplied mounting hardware to minimize vibrations.

Connect power supply within 5-24V DC range, observing polarity and grounding best practices.

Connect the output signals (A, B, Z channels) to control system input while shielding cables from electromagnetic noise.

Routine maintenance includes periodic cleaning to remove dust buildup and inspection of electrical connections for tightness.

Avoid exposing the encoder to extreme shocks or chemical contaminants.

Replace the encoder promptly if signal instability or mechanical damage occurs.

Application Scenarios:

Industrial motors for precise rotational position feedback

Conveyor systems requiring speed monitoring and control

Robotics for accurate joint and axis movement detection

Packaging machinery for synchronization and counting operations

Printing machines to monitor roller rotation speed and position

Automated assembly lines for precise motion control

今すぐ見積もりを依頼する

24時間以内にご返信いたします。