GOS38A04インクリメンタルロータリエンコーダは、要求の厳しい産業オートメーション環境における精密な動作と位置のフィードバック用に設計されています。堅牢な38mmシャフトとカスタマイズ可能な最大600パルス/回転(PPR)の分解能を特長とするこのエンコーダは、速度、位置、および方向を検出するアプリケーションに理想的な信頼性と精度の高いAB矩形信号を提供します。耐久性を考慮して設計されたこのエンコーダは、頑丈な構造と安定した出力信号で多様な設置に対応し、多様なオートメーションシステムやモーションコントロールシステムで長期間にわたって性能を発揮します。

主な特徴

ヘビーデューティ仕様のシャフト径38mm。

最大600 PPRまでカスタマイズ可能な分解能による精密測定

高ノイズ耐性を備えた標準AB矩形波出力信号

産業環境に適した堅牢な構造

時計回り、反時計回り両方の回転検知に対応

リファレンスマーキングと原点復帰のためのゼロパルス(Zチャンネル)(オプション

製品の利点

高い精度と再現性でシステムの信頼性を向上

振動や衝撃に強い耐久性のある機械設計

柔軟な出力オプションにより、PLC、コントローラ、産業用ドライブとの統合が容易

過酷な条件下でも安定した性能を発揮する長寿命設計

低い始動トルクが摩耗を減らし、ギアボックスとモーターの寿命を延ばす

メンテナンスが容易な設計による費用対効果の高いソリューション

製品モデルとその意味

| G | 0 | S | 38 | □ | A | 04 | 1000 T | 3 | 2M | ||||

| カテゴリー 製品 | 製品の種類 | フォーム メインシャフト | 輪郭 製品 | メインのサイズ シャフト、シャフトホール | アウトレット シーリングフォーム | 概要構成 | 決議 | 出力形式 | 出力信号 | ケーブル | |||

| G:インクリメンタル タイプ | 0:megneto- 電気 | S:ソリッドシャフト | 38:φ38mm | φ6mm | A:サイドアウトレットゴム | 04:4概要 構造4 | 10,20,50, 60,100, 200,360, 400,500 600,800, 1000,1024,1200, 2000,2048,2500,3000,3600, 4096 | T:プッシュプル出力 L:5Vドライブ出力 A:24Vドライブ出力 | 1相信号 2:AB相AB信号 3:ABZ相ABZ信号 4:位相ABA/B/信号 5:ABZA/B/Z/相信号 | デフォルト 2m 2mでない場合、ラベリングは十分である。 | |||

配線表

| ラインカラー | T出力信号 | – | ラインカラー | L/A出力信号 |

| ブラウン | ブイシーシー | ブラウン | ブイシーシー | |

| 青 | GND | |||

| 青 | GND | |||

| ブラック | A段階 | |||

| ブラック | A段階 | ホワイト | Bフェーズ | |

| オレンジ | Z相 | |||

| ホワイト | Bフェーズ | |||

| ブラックレッド | 相 | |||

| オレンジ | Z相 | ホワイトレッド | B相 | |

| オレンジレッド | Z相 | |||

| シールド | F -G | |||

| シールド | F -G |

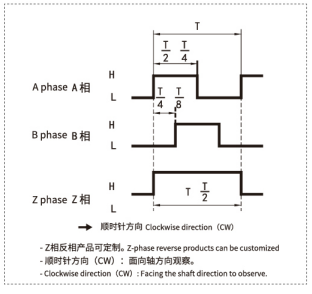

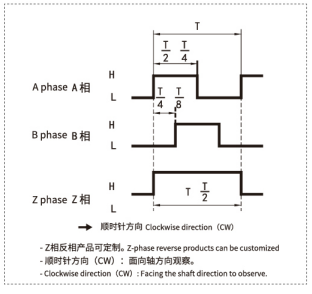

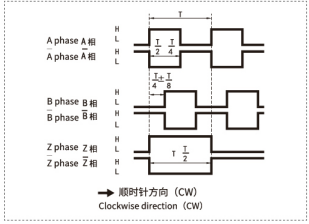

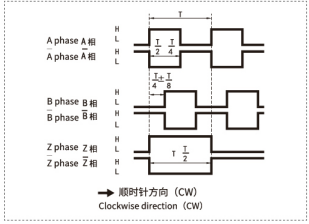

出力位相差

プッシュプル出力

ロングライン・ドライブ出力

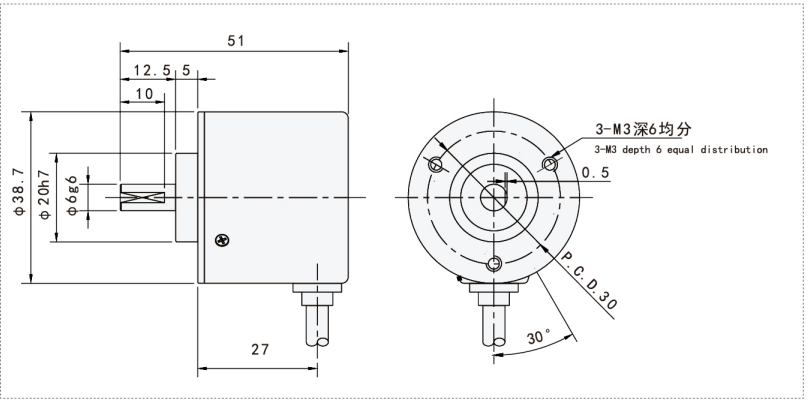

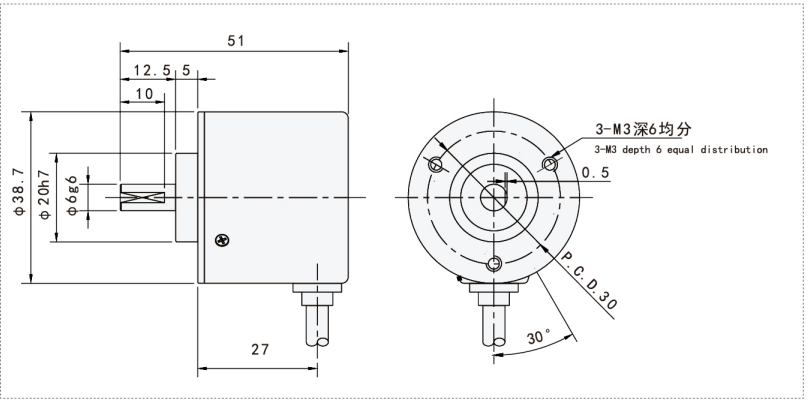

機械図面(mm)

設置手順とメンテナンス

エンコーダシャフトを回転機器のシャフトにしっかりと固定し、機械的ストレスを避けるために適切なアライメントを確保します。

エンコーダ出力ケーブルを制御システムの入力に接続し、ABZの信号仕様に従って配線を確認します。

カスタマイズが可能な場合は、希望する分解能とパルスカウントを設定する。

信号出力と方向検出精度を確認するため、初期回転テストを行う。

定期的にエンコーダと接続部に汚れ、ゴミ、摩耗がないか点検し、最適な機能を維持するために優しく清掃してください。

取扱説明書で指定されている場合は、ベアリングに注油する(ほとんどのモデルは密閉式でメンテナンスフリー)。

アプリケーション

正確な角度位置フィードバックを必要とする産業オートメーションとロボット工学

工具の位置決めと速度制御のためのCNC機械

正確なモーションモニタリングのためのコンベアシステムと包装機

同期化された速度および位置検出のための印刷機械

高精度の回転フィードバックを必要とする医療機器用機器

モーター位置確認用エレベーターとエスカレーター

今すぐ見積もりを依頼する

24時間以内にご返信いたします。