GLS50Hロータリーエンコーダは、要求の厳しい機械やオートメーションアプリケーション向けに設計された、信頼性の高い一貫した回転フィードバックを提供します。堅牢な構造と多彩な出力オプションで設計されたこのエンコーダは、安定した速度信号と位置信号を提供し、スムーズなモーショントラッキングとシステム効率をサポートします。耐久性に優れた設計と設置の容易さにより、幅広い産業環境に適しています。

主な特徴

安定したパルス信号を出力する高分解能インクリメンタル出力

埃、湿気、振動から保護する頑丈な密閉筐体

TTLおよびオープンコレクタ出力形式をサポートし、柔軟な統合を実現

標準フランジ取り付けとシャフトカップリングで取り付けが簡単

プレミアムベアリングが長寿命を実現

幅広い電圧入力範囲により、さまざまな電源要件に対応

製品の利点:

信頼性の高い安定した動作フィードバックを提供し、操作の一貫性を強化

過酷な環境下でもダウンタイムを最小限に抑える頑丈な設計

柔軟な出力と取り付けオプションでシステム統合を合理化

限られたスペースに設置可能なコンパクトサイズ

低メンテナンス要件により、システム全体の稼働時間を向上

製品モデルとその意味

| G | L | S | 50 | □ | H | 1000 | T | 3 | 2M | ||||

| カテゴリー 製品 | 製品の種類 | フォーム メインシャフト | 輪郭 製品 | メインのサイズ シャフト、シャフトホール | アウトレット シーリングフォーム | 決議 | 出力形式 | 出力信号 | ケーブル | ||||

| G:インクリメンタル・タイプ | L:光電子 トリシティ | S:ソリッドシャフト | 50:φ50ミリ | □:Φ8mm | H:リアアウトレット・プラスチック | 10,20,50, 60,100, 200,360, 400,500, 600,800, 1000,1024,1 200,2000,20 48,2500,300 0,3600,4096 | C:オープンコレクタ出力 T:プッシュプル出力 L:5V 5Vドライブ出力 A:24Vドライブ出力 | 1:A相信号 2:AB相信号 3:位相ABZ信号 4:位相ABA/B/信号 6:ABZA/B/Z/相信号 | デフォルト 2m ライン、非2m用、 レッテル貼りで十分 | ||||

配線表

| ラインカラー | C/F/T出力信号 | ラインカラー | L/A出力信号 | |

| ブラウン | ブイシーシー | ブラウン | ブイシーシー | |

| 青 | GND | |||

| 青 | GND | |||

| ブラック | A段階 | |||

| 禿 | A段階 | ホワイト | Bフェーズ | |

| 範囲 | Z相 | |||

| ホワイト | Bフェーズ | |||

| 赤 | A段階 | |||

| オレンジ | Z相 | 灰色 | B相 | |

| イエロー | Z相 | |||

| シールド | F -G | |||

| シールド | F -G |

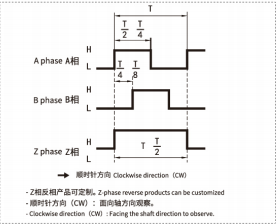

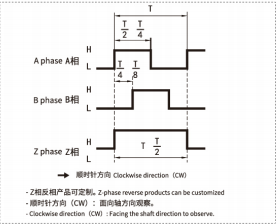

出力位相差

相補出力NPNコレクタオープン回路出力

ロングライン・ドライブ出力

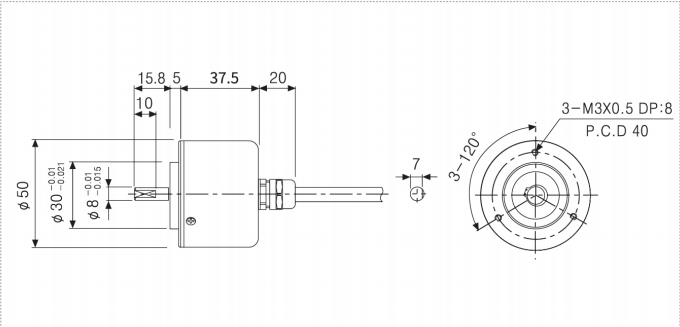

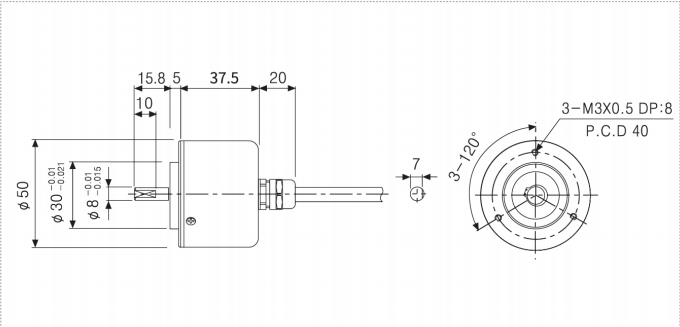

機械図面(mm)

インストールとメンテナンス:

付属のカップリングまたはアダプターを使用して、GLS50H エンコーダをシャフトにしっかりと取り付けてください。

機械的ストレスや不正確な読み取りを避けるため、シャフトのアライメントが適切であることを確認してください。

提供された回路図に従って正確に配線を接続し、電源と信号が正しいことを確認する。

本格的な配備の前に、お使いの制御システムで出力信号のテストを実施してください。

ホコリやゴミが溜まらないように、エンコーダ本体を定期的に清掃してください。

ハードウェアおよび接続部を定期的に点検し、推奨に従ってベアリングに注油する。

詳細な製品用途

GLS50Hエンコーダは、以下のような様々なアプリケーションに適しています:

コンベアとマテリアルハンドリングシステムによる速度と位置の監視

信頼性の高いモーション信号を必要とするロボットおよびオートメーション機器

工程同期のための包装機と印刷機

エレベーター、エスカレーター、リフトのスムーズで安全なシャフト監視

ブレード位置フィードバックのための風力タービンのような再生可能エネルギーシステム

厳しい環境での農業機械と重機

信頼性の高い回転検知を必要とする医療機器および検査機器

GLS50H のようなロータリーエンコーダは、自動システムや機械システム全体のモーションフィードバックの信頼性を向上させる上で重要なコンポーネントです。エンコーダ技術の進歩は、厳しい条件下での継続的な動作を保証するために、耐環境性とシグナルインテグリティの向上に重点を置いています。アライメントや配線精度などの適切な取り付け技術は、エンコーダの寿命と性能に大きく影響します。また、エンコーダを最新のデジタル制御プラットフォームと統合することで、予知保全とシステム診断が可能になり、よりスマートで効率的な機械操作への道が開かれます。

今すぐ見積もりを依頼する

24時間以内にご返信いたします。